|

SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS |

| << MICROEMULSION TECHNIQUES:Significance of Packing Parameter |

| NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials >> |

Chapter

- 8

SYNTHESIS

BY SOLID STATE

DECOMPOSITION

S.

Navaladian

INTRODUCTION

Synthesis

of materials is an important part in

materials science and chemistry

because the

properties

of materials vary drastically

based on their synthetic

method. Even the

stability

of

the material varies based on

method by which it is synthesized. By

varying synthetic

methods,

surface area, pore size,

crysatallite size, allotropes,

morphology, presence of

impurities,

defects and other oxidation state of

the metal can also be varied.

Hence, their

potential

to certain applications vary

drastically. For example, in

catalysis, catalyst

with

high

surface area is preferred to

achieve high conversion. So,

synthetic method that

yield

high

surface of the catalyst is adopted. A

lot of methods are known in

the synthesis of

materials

of various applications in different

fields, still efficient and

cost-effective

methods

are being developed.

DECOMPOSITION

METHODS

Decomposition

is one of the methods known in

the synthesis of various

materials.

In

this

method,

a solid or liquid is heated to

its decomposition temperatures to obtain

the solid of

interest.

For example, sugar can be decomposed in

an inert atmosphere to get the

carbon

material

(solid-to-solid). Decomposition of

titanium isopropoxide (a liquid) in

air

atmosphere

is used to get the titanium

dioxide (TiO2)

(liquid-to-solid). Ni(CO)4, a

volatile

complex

can be decomposed to get Ni metal

(vapour-to-solid). In this particular

chapter,

solid

state decomposition is considered.

Solid-State

Decomposition

Decomposition

of any material occurs due to

its instability when the

particular conditions

are

applied. Also, it depends

upon the activating source. These

activating sources can be

thermal,

photochemical, microwave and γ-radiation.

For example chemical

compound

which

need high temperatures to decompose can

be photochemically decomposed

with

ease

at room temperature. Particularly,

the decomposition of AgBr to Ag can be

achieved

by

thermal modes only at 1330�C

but it can be easily decomposed at

room temperature

under

visible light. As we know,

this principle is used in

photography. Thus, based on

the

activating

sources, solid-state decomposition can be

classified into the

following

8.2

Synthesis

by Solid State

Decomposition

decomposition

methods (1) thermal

decomposition, (2) Microwave-assisted and

(3)

Photochemical

decomposition.

Thermal

Decomposition Methods

In

general, thermal decomposition

methods are chosen for

synthesis of metal

oxides.

Decomposable

precursors which posses low

decomposition temperature are

preferred for

the

synthesis because at high

temperatures, sintering is also high. So

materials formed

will

have poor surface area and

large crystallite size.

Decomposition temperature of

any

compounds

is mainly decided by the

redox properties of the

compound. In general, salts

of

the silver with easily

utilizable organic moiety can be

decomposed at lower

temperatures.

Various materials such as

metal, metal oxides, mixed

metal oxides and

metals

chalogenides have been synthesized

using decomposition

method.

Synthesis

of Metals

100

a

b

95

90

85

80

75

70

40

60

80

100 120 140 160

180 200

ο

Temperature

( C )

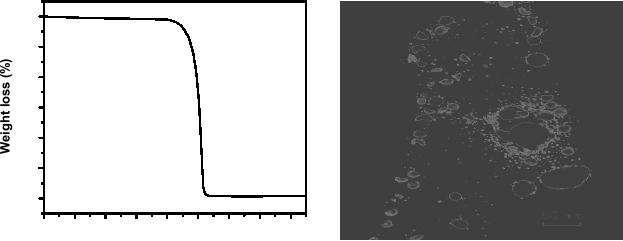

Fig.

8.1. TGA profile of silver

oxalate and (b) silver

nanoparticles synthesized by

decomposition

of silver oxalate

[1].

Synthesis

of metallic silver can be achieved

using silver formate, silver

oxalate, oleate,

maleate

and fumarate and their decomposition

temperature is 93, 140, 287,

170 and 280

�C

respectively (1 and 2). Recently

silver dodecanate, myristate and

palmitate also have

been

utilized for the synthesis

of silver nanopartices. Decomposition of

these silver

compounds

yield various gaseous

products like CO, CO2 and

organic residues. In the

case

of silver oxalate decomposition to Ag

metal and CO2 are

produced. Hence, this

is

one

of the methods known for

the production pure CO2. In

the case of silver

oxalate

Synthetic

Strategies in Chemistry

8.3

decomposition,

reaction was carried out in a

water medium under refluxing

conditions at

under

N2 atmosphere

with a capping agent (poly

(vinyl alcohol)) (Fig. 8.1).

TGA of the

silver

oxalate, given in Fig. 8.1

(a) shows the sharp

decomposition at around 140 �C.

The

corresponding

weight loss is due to the loss of two

moles of CO2.

TEM image of Ag

nanoparticles

synthesized by decomposition of silver

oxalate is given in Fig.

8.1(b). The

average

particle is around 7

nm.

Metal

Oxides

Metal

oxides can also be synthesized by

decomposition of certain precursors

like

hydroxides,

oxalates, hydroxyl carbonates, hydroxyl

sulphates and carbonates. In

general,

the

direct calcination of metal

salt such as nitrates and

sulphates is not carried out

to

synthesis

the metal oxides in order to

avoid the impurities and

heterogeity of the

materials.

Synthesis

of Magnesia

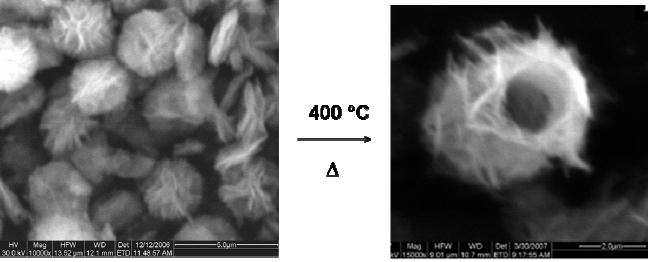

The

decomposition of magnesium

hydroxycarbonate (Mg5(CO3)4(OH)2)

yields

magnesium

oxide (MgO). In this

particular case, the

morphology of the precursor

is

flower

like particle of 3 �m. After

calcinations at 400 �C, MgO

with tube-like

morphology

is obtained as shown in Fig.

8.2.

ο

Mg5 (CO3 )4 (OH)2 400→

5

MgO +

4CO2 + H2O

C

(a)

(b)

Fig.

8.2 SEM image of (a)

magnesium hydroxycarbonate and (a)

MgO [3].

8.4

Synthesis

by Solid State

Decomposition

Similarly

MgSO4.5Mg(OH)2.2H2O

also yields the MgO by

decomposition, but

the

complete

decomposition needs temperature above 800

�C.

In this case, morphology

of

the

particles is strip-like. In general,

MgO is synthesized decomposing the

Mg(OH)2 in

the

air. But MgO synthesized in

the presence of air shows

less surface area than

that of

MgO

synthesized in nitrogen atmosphere. This

is due to the high amount of

sintering in

presence

of oxygen.

Synthesis

of Matel Oxides from Oxalate

Precursors

Due

to the low temperature

decomposition of metal oxalates,

oxalate precursors are

most

widely

used for syntheses of metal

oxides. Nickel,

copper, iron and zinc oxides

can be

synthesized

directly decomposing their

oxalate precursor. Nickel

oxalate precursor has

yielded

nickel oxide with sizes

around 9 nm at 450 �C. Fe2O3 has

been synthesized by

thermal

decomposition of ferrous oxalate at 415

�C.

When copper oxalate has

been

decomposed

in air at 300 �C for 1 h

mesoporous CuO microspheres have been

obtained

(Fig.

8.3). Zinc oxalate has

yielded ZnO particles of size

around 55 nm. In all these

cases,

the

formation of CO and CO2 are

the by products. Zinc

acetate also decomposes and

yields

the zinc oxide at 600 �C.

Stoichiometric barium titanate

(BaTiO3)

is synthesized

by

thermal decomposition of bariumtitanyl

oxalate at 600 �C.

Fig.

8.3. Copper oxide micropshere

obtained by the decomposition of copper

oxalate [4].

Synthetic

Strategies in Chemistry

8.5

Metal

Chalcogenides

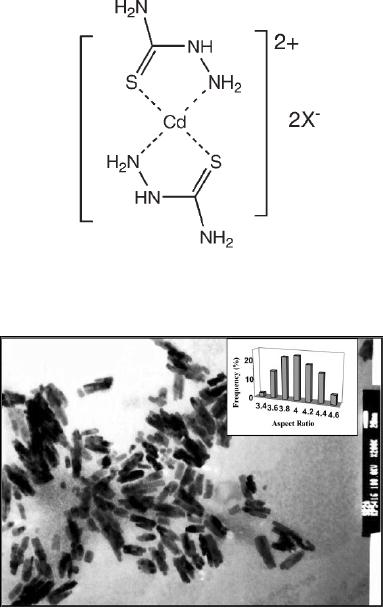

Cd(II)complex

of thiosemicarbazide and selenosemicarbazide are

thermally decomposed

to

obtain CdS and CdSe. In

typical procedure 500 mg of cadmium

tetramethylthiourea

complex

was mixed with 182 mg of

thiosemicarbazide ligand, dispersed

well in 3 ml tri-

n-octylphosphine

oxide (TOPO). This precursor

mixture was injected into

TOPO (5 g) at

300

�C.

The resulting orange yellow

solution was maintained at 300 �C for

about 1 h and

then

cooled to 70 �C. TEM image of

CdS nanorods formed are

shown in Fig. 8.4. In

this

case

the thicknesses of the rods formed

are 15 nm and aspect ratio is

3-4.

Cadmium

thiosemicarbazide

Fig.

8.4. CdS nanorods

synthesized by decomposition of cadmium

thiosemicarbazide [5]

8.6

Synthesis

by Solid State

Decomposition

Microwave-assisted

Decomposition

In

general, microwave is used to

quicken the reactions. The

main advantages of

microwave

assisted processes are: (i)

the rate of the reaction is

increased by orders of

magnitude,

(ii) the initial heating

process is rapid, and (iii)

microwaves induce the

generation

of localized high temperatures at

reaction sites, which enhances

the reaction

rates.

Moreover, microwave-based syntheses are

energy efficient. Hence,

microwave is

used

in the synthesis of materials as

well as organic

compounds.

Synthesis

of Metals

Decomposition

of silver oxalate has been

carried out by using

microwave radiation in

ethylene

glycol and diethylene glycol.

Formation of silver nanoparticles

has been

observed

in 60 s in the case of ethylene

glycol. In the case of

diethyelene glycol,

only

after

75 s of irradiation, the formation of

silver nanoparticles has

been observed. Ag

nanoparticle

formed in ethylene glycol

medium is given in Fig. 8.5

(a). Formation of

anisotropic

nanoparticle is observed in the case of

75 s of microwave irradiation (see

for

example

Fig. 8.5 (a)).

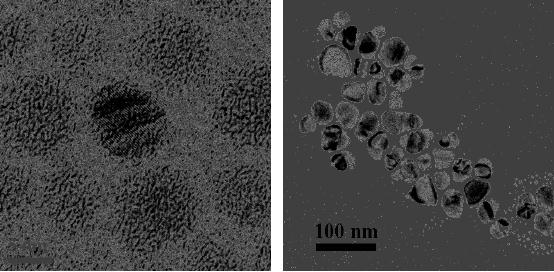

a

b

Fig.

8.5. TEM images of Ag nanoparticles

formed in (a) 60 s and (b) 75 s of

microwave

irradiation

[6].

Synthesis

of Metal Oxides

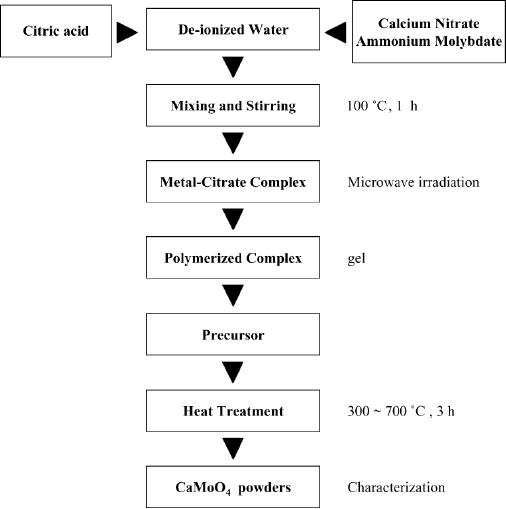

CaMoO4 has been synthesized at

low temperatures by a modified

citrate complex

method

using

microwave irradiation. Synthesizing

mixed metal oxides at low

temperatures is a

Synthetic

Strategies in Chemistry

8.7

tedious

process an it needs high

temperatures. As a result, the

resulting material has

poor

surface

area and larger crystallite

size. For this kind of

purpose, microwave can be used

to

effectively bring down the

temperature required for the

formation of mixed

metal

oxides.

A flow chart for the

synthesis of CaMoO4 is

given Scheme 8.1. In this

case, citric

acid

makes a complex with the

metal ions and due to the

presence of the citrate,

the

formation

of the nanoparticles is observed. This

method is also known as citric

acid

combustion

method. The corresponding

nanoparticles of CaMoO4 formed

are shown in

Fig.

8.6.

Scheme

8.1. Flow chart of the

synthesis of CaMoO4 by

microwave assisted route

[9]

8.8

Synthesis

by Solid State

Decomposition

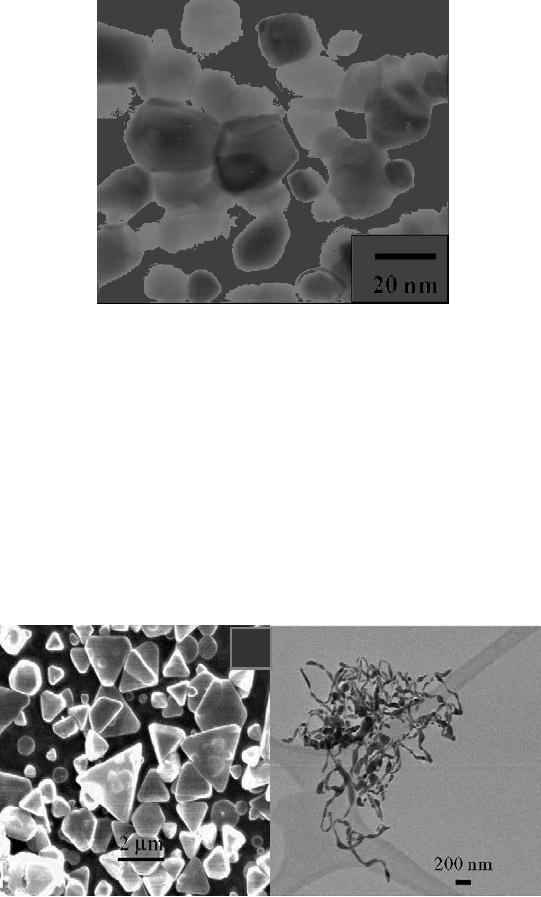

Fig.

8.6. TEM image of CaMoO4 nanoparticle

synthesized at 600 �C for 3 h

[9]

Photochemical

Decomposition Method

Synthesis

of Metals

Silver

nanowires have been

synthesized using photographic

principles. In this case,

AgBr

is

reduced by in presence of a fluorescent

light and followed by the

development of the

film.

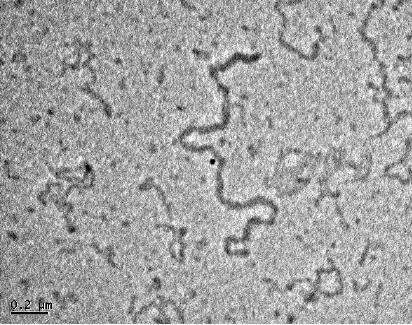

TEM images AgBr and Ag nanowires

formed from this process

are shown in Fig

8.7.

a

b

Fig.

8.7. TEM images of (a) AgBr

and (b) Ag nanowire

[10]

Synthetic

Strategies in Chemistry

8.9

Synthesis

of Metal Oxides

Iron

oxide Nanoparticles

Nanoparticles

of iron oxide have been

synthesized by decomposing

Fe(CO)5 under

ultraviolet

light. During the

photolysis, decomposition of

Fe(CO)5 takes

place to form

nanoparticles

of iron metal and further it

turns into iron oxide due to

the instability of

iron

nanoparticles.

Synthesis

of EuO nanocrystals

In

a quartz vessel, Eu(NO3)3 (37.5

mM) and urea (112.5 mM) were dissolved in

methanol

(400

ml) under an N2 atmosphere,

and the solution was irradiated

with a 500-W high-

pressure

mercury arc lamp at 25�C. A

yellowish powder precipitated

after 30 min. After

24

h of irradiation, the powder was

separated by centrifugation and washed

with

methanol

several times.

Synthesis

of CdS nanorod

Fig.

8.8. TEM image of CdS nanowires

synthesized by photochemical method

[11].

CdS

nanorods have been

synthesized using cadmium

salt, DNA base pairs and

thioacetamide

(TAA). Photo-irradiation was performed by

directly placing the

cuvette

containing

the mixture of DNA, Cd salt,

and TAA solutions under 260 nm UV

light

8.10

Synthesis

by Solid State

Decomposition

irradiation

for six hours. The

initially occurring

DNA-Cd2+ complex formation

was

confirmed

by a shift in the UV-vis

spectrum of the mixed

solution compared to the

pure

DNA.

After photo-irradiation the

UV-vis spectrum was again recorded

showing the

formation

of CdS nanoparticles. Thioacetamide

acts as sulphur source in this

reaction.

The

corresponding CdS nanowires

formed are shown in TEM image in

Fig. 8.8.

SUMMARY

Solid

state decomposition methods

are important in the

synthesis of the material

both in

nano

size ranges as well as in bulk. In

the case of thermal

decomposition route,

the

compound

having lower decomposition

temperature is preferred. The

decomposition

temperature

of the compound is mainly

based on the redox potential

of cation and anion

of

the compound. Microwave-assisted

syntheses are more advantageous

than

conventional

heating due to the increased rate of

the reaction. Photochemical

synthetic

methods

are also advantageous due to fact that

the material is formed at

ambient

conditions

so that the sintering of the

materials is reduced.

REFERENCES

1.

S.

Navaladian, B. Viswanathan, R. P.

Viswanath and T. K. Varadarajan,

Nanoscale

Research Letter,

2

(2007) 44.

I.

K. Shim, Y. L. Lee, K. J. Lee, J. Joung, Materials

Chemistry and

Physics,

2.

(2008)

(in press).

3.

C.

M. Janet, B. Viswanathan, R. P. Viswanath and T. K.

Varadarajan, Journal

of

Physical

Chemistry C,

111 (2007) 10267.

4.

R.

N. Nickolov,

B.

V. Donkova, K. I. Milenova1 and D. R.

Mehandjiev,

Adsorption

Science & Technology,

24 (2006) 497.

5.

P.

S. Nair, T. Radhakrishnan, N. Revaprasadu, G. A.

Kolawole and P.

O'Brien,Chemiacl

Communication (2002)

564.

6.

S.

Navaladian, C. M. Janet, B. Viswanathan, R. P.

Viswanath and T. K.

Varadarajan,

Nanotechnology, 19 (2008) 045603.

7.

X.

Wang, J. Song, L. Gao, J. Jin, H.

Zheng and Z. Zhang, Nanotechnology

16

(2005)

37.

8.

Z.

Zhou, Q. Sun, Z. Hu, and Y.

Deng, Journal

of Physical Chemistry C,

110

(2006)

13387.

Synthetic

Strategies in Chemistry

8.11

9.

J.

H. Ryu, J.-W. Yoon, C. S.

Lim, W.-C. Oh and K. B. Shim,

Journal

of Alloys

and

Compounds, 390 (2005)

245.

10.

C.

Liewhiran, S. Seraphin, S. Phanichphant,

Current Applied Physics, 6

(2006)

499.

11.

S.

Liu, R. J. Wehmschulte, G. Lian and C. M.

Burba, Journal

of Solid State

Chemistry, 179

(2006) 696.

Table of Contents:

- INTRODUCTION TO SYNTHETIC STRATEGIES IN CHEMISTRY:POROUS MATERIALS

- SYNTHETIC METHODS BASED ON ACTIVATING THE REACTANT:HALOGENATION OF BENZENE

- METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method

- SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE

- SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE

- TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway

- MICROEMULSION TECHNIQUES:Significance of Packing Parameter

- SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS

- NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials

- THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible

- ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS

- NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC

- SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY

- SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice

- CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES

- SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY

- COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES