|

SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY |

| << CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES |

| COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES >> |

Chapter

- 16

SOME

CONCEPTUAL DEVELOPMENTS IN SYNTHESIS

IN

CHEMISTRY

Joyce

DSouza

INTRODUCTION

Synthesis

of materials play a crucial

role in designing and discovering

new materials and

also

in providing better and less cumbersome

methods for preparing known

chemicals.

Most

of the ten million or so

chemical compounds that are

known today, can be

classified

into

a relatively small number of

subgroups or families.

More

than 90 percent of the

compounds are organic

compounds. In turn,

organic

compounds

can be further subdivided into a

few dozen major families

such as the

alkanes,

alkenes, alkynes, alcohols, aldehydes,

ketones, carboxylic acids, and amines.

An

important

subset of organic compounds

include biochemical compounds

with four major

families:

carbohydrates, proteins, nucleic acids,

and lipids.

Because

of their unique properties,

multi-carbon compounds exhibit

extremely large

variety

and the range of application of organic

compounds is enormous. They

form the

basis

of important constituents of many

products and apart from a very

few exceptions,

they

form the basis of all

earthly life processes. The

different shapes and

chemical

reactivities

of organic molecules provide an

astonishing variety of functions,

like those of

enzyme

catalysts in biochemical reactions of

live systems. The autopropagating

nature of

these

organic chemicals is what

life is all about. Products

such as plastics,

synthetic

fibres,food,

explosives, paints and pigments,

pharmaceuticals and pesticides and

many

others

have become readily

available through the

dynamic development of

organic

synthesis.

Inorganic

compounds are typically

classified into one of five

major groups: acids,

bases,

salts, oxides, and others. A

large class of compounds

discussed in inorganic

chemistry

textbooks are coordination

compounds. Examples range from

species that are

strictly

inorganic, such as

[Co(NH3)6]Cl3,

to organometallic compounds such

as

Fe(C5H5)2 (ferrocene)and

extending to bioinorganic compounds,

such as the hydrogenase

enzymes.

Major classes of inorganic

compounds that are studied

under materials

science

tend

to be polymeric (non-molecular) and

refractory, and often are of

commercial interest

16.2

Some

Conceptual Developments in Synthesis in

Chemistry

such

as a)alloys: brass, bronze, stainless

steel; b)semiconductors : silicon ,

gallium

arsenide;

c)superconductors : yttrium barium copper

oxide .

SYNTHETIC

ORGANIC CHEMISTRY

Synthetic

organic chemistry is an applied

science as it borders engineering

involving

design,

analysis, and/or construction of

work for practical purposes.

Organic synthesis of

a

novel compound is a problem

solving task, where a

synthesis is designed for a

target

molecule

by selecting optimal reactions from

optimal starting materials.

Complex

compounds

can have several reaction

steps that sequentially

build the desired

molecule.

The

synthesis proceeds by utilizing

the reactivity of the

functional groups in

the

molecule.

For example, a carbonyl

compound can be used as a nucleophile by

converting

it

into an enolate, or as an electrophile,

and the combination of the

two is called the

aldol

reaction.

Designing practically useful syntheses

always requires conducting

the actual

synthesis

in the laboratory. The

scientific practice of creating

novel synthetic routes

for

complex

molecules is called total

synthesis.

There

are several strategies to design a

synthesis. The modern method

of

retrosynthesis,

developed by E.J. Corey, starts with

the target molecule and splices it

to

pieces

according to known reactions.

The pieces, or the proposed

precursors, are

further

spliced

until ideally inexpensive and

available starting materials

are reached. Then,

the

retrosynthesis

is written in the opposite direction to

give the synthesis. A

"synthetic tree"

can

be constructed, because each

compound and also each precursor

have multiple

syntheses.

Retrosynthetic

Analysis

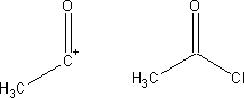

Disconnection:

A retrosynthetic step involving

the breaking of a bond to

form two (or

more)

synthons.

Synthon

Synthetic

equivalent

Synthetic

Strategies in Chemistry

16.3

Retron:

A minimal molecular substructure

that enables certain

transformations.

Retrosynthetic

tree: A directed acyclic

graph of several (or all)

possible retrosyntheses of

a

single target.

Synthon:

An idealized molecular fragment. A

synthon and the

corresponding

commercially

available synthetic equivalent

are shown below:

Target:

The desired final

compound.

Transform:

The exact reverse of a synthetic

reaction; the formation of

starting materials

from

a single product.

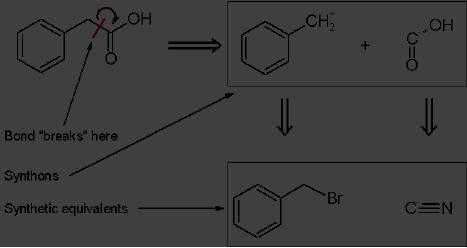

An

example will allow the

concept of retrosynthetic analysis to be

easily understood.

In

planning the synthesis of

phenylacetic acid, two

synthons are identified.

A

nucleophilic

"-COOH" group, and an electrophilic

"PhCH2+"

group. Of course, both

synthons

do not exist per se;

synthetic equivalents corresponding to

the synthons are

reacted

to produce the desired

product. In this case, the

cyanide anion is the

synthetic

equivalent

for the -COOH

synthon, while benzyl

bromide is the synthetic

equivalent for

the

benzyl synthon.

The

synthesis of phenylacetylene determined

by retrosynthetic analysis is

thus:

1.

PhCH2Br

+ NaCN → PhCH2CN +

NaBr

2.

PhCH2CN

+ 2 H2O → PhCH2COOH + NH3

16.4

Some

Conceptual Developments in Synthesis in

Chemistry

STRATEGIES

Functional

Group Strategies:

Manipulation of functional groups can

lead to significant

reductions

in molecular complexity.

Stereochemical

Strategies:

Numerous chemical targets have

distinct stereochemical

demands.

Stereochemical transformations (such as

the Claisen rearrangement

and

Mitsunobu

reaction) can remove or transfer

the desired chirality thus

simplifying the

target.

Structure-Goal

Strategies: Directing

a synthesis towards a desirable

intermediate can

greatly

narrow the focus of an

analysis. This allows

bidirectional search

techniques.

Transform-based

Strategies:

The application of transformations to

retrosynthetic

analysis

can lead to powerful reductions in

molecular complexity.

Unfortunately,

powerful

transform-based retrons are

rarely present in complex molecules, and

additional

synthetic

steps are often needed to

establish their

presence.

Topological

Strategies:

The identification of one or more

key bond disconnections

may

lead

to the identification of key

substructures : Disconnections that

preserve ring

structures

are encouraged; Disconnections

that create rings larger

than 7 members are

discouraged.

SYNTHETIC

INORGANIC CHEMISTRY

Advances

in inorganic chemistry have

made significant contributions to

modern living.

For

instance, synthetic fertilizers

manufactured from inorganic

chemicals have

increased

worldwide

crop production. Inorganic

substances used to fabricate

silicon chips help

power

the global information age.

Metal alloys are used in

automobiles and aircraft to

make

them lighter and stronger. Companies

use inorganic compounds to

fabricate

concrete,

steel, and glass--materials used to

construct buildings, infrastructure, and

other

public

works around the world. In

the United States, 10 of the

11 most commonly

produced

chemicals are derived from

inorganic elements. These 10 inorganic

chemicals

(presented

below in descending order of production)

are used in a wide variety

of

applications.

Sulfuric acid is used to make

fertilizers, synthetic fibers, and

metals.

Synthetic

Strategies in Chemistry

16.5

Nitrogen

is used in recovering underground

petroleum deposits, in the production

of

ammonia,

and as a blanketing material for

shipping perishables such as fruits

and

vegetables.

Oxygen is used in the

production of steel and plastics, in

medical

applications,

and in rocketry. Lime is used in

the manufacture of steel and

cement.

Ammonia

is combined with sulfuric acid to make

ammonium sulfate the most

important

of

the synthetic fertilizers.

Sodium hydroxide is used in

the manufacture of paper,

soap,

detergents,

and synthetic fibers, and is also a

caustic material used as a

drain cleaner.

Chlorine

is used to manufacture vinyl

chloride plastic, to disinfect

drinking water, and to

bleach

paper during manufacturing.

Phosphoric acid is used to give

soft drinks a tart

flavor

and to make fertilizers. Sodium carbonate is

used in the production of

glass, paper,

and

textiles. Nitric acid is used to make

synthetic fibers, such as

nylon; explosives,

such

as

nitroglycerin and TNT (trinitrotoluene); and is also

combined with ammonia to

make

fertilizer.

Because

of its direct relevance to

products of commerce, solid

state inorganic

chemistry

has been strongly driven by

technology. Applications discovered in

the 20th

century

include zeolite and platinum-based

catalysts for petroleum processing in

the

1950's,

high-purity silicon as a core component

of microelectronic devices in the

1960's,

and

"high temperature" superconductivity in

the 1980's. The invention of

X-ray

crystallography

in the early 1900s by

William Lawrence Bragg enabled

further

innovation.

Although some inorganic

species can be obtained in pure

form from nature,

most

are synthesized in chemical

plants and in the

laboratory.

There

is much chemical ingenuity in

the synthesis of solid

materials. While

tailor-

making

of materials of the desired

structure and properties remains

the main goal of

solid

state

chemistry and material science, it is

not always possible. However, a

rational

approach

to the synthesis of solids

may be evolved which

requires an understanding of

the

principles of crystal chemistry, and of

thermodynamics, phase equilibria and

reaction

kinetics.

Synthetic

Strategies

Various

types of chemical reactions

have been used for

the synthesis of solid

materials.

Some

of common reactions employed

for the synthesis inorganic

solids are listed

below:

16.6

Some

Conceptual Developments in Synthesis in

Chemistry

(1)

decomposition

B(s) + C(g)

A(s)

(2)

combination

C(s)

A(s) +

B(g)

(3)

metathetic [combining (1) and

(2) above]

C(s)

+

D(g)

A(s) +

B(g)

(4)

addition

C(s)

A(s) +

B(s)

C(s)

A(s) +

B(l)

C(s)

A(g) +

B(g)

(5)

exchange

AY(s)

+

BX(s)

AX(s) +

BY(s)

AY(s)

+

BX(g)

AX(s) +

BY(g)

More

complex reactions involving

more than one type of

reaction are also

commonly

employed

in solid state synthesis.

For example, in the

preparation of complex oxides, it

is

common

to carry out thermal

decomposition of a compound followed by

oxidation (in air

or

O2 )

essentially in one step:

CaMnO3(s) + 2CO2(g)

2Ca0.5Mn0.5CO(s)

+ 1/2 O2(g)

O2

MgO(s)

+ Cr2O3(s)

MgCr2O4(s)

Specific

reagents and reaction conditions

are employed to carry out

various processes

such

as reduction, oxidation and halogenation

in the synthesis of

solids.

Synthetic

Strategies in Chemistry

16.7

Reduction

of oxides, for instance, may

be carried out

in

an atmosphere of (flowing) pure or dilute

hydrogen or CO.

�

by

heating oxides in argon or

nitrogen for the purpose of

lowering the oxygen

�

content

by

application of vacuum at an appropriate

temperature (vacuum annealing

or

�

decomposition

at low pressures)

The

obvious means of reducing

solid compounds by hydrogen is

employed not only

for

reducing

oxides, but also halides and

other compounds. Thermal

decomposition of metal

halides

also yields lower

halides:

2MO(s)

+ H2O(g)

M2O3(s) + H2(g)

(eg.

M = Fe)

ABO2.5(s)

+ 1/2H2O(g)

ABO3(s) + H2(g)

(e.g.

LaCoO3)

MCl2(s) + HCl(g)

MCl3(s) + H2(g)

(eg.

M = Fe)

heat

(eg.

M = Fe)

MX2 +

1/2X2

MX3

Reduction

of oxides and halides can also be

accomplished by reacting with

elemental

carbon

or with a metal.

3MCl2 (e.g. M = Nd, Fe)

2MCl3 +

M

3MCl3(s) + M'Cl3(g)

3MCl4 +

M'(s)

(e.g.

M = Hf, M' = Al)

M2O3

+ 3M

5MO

(e.g.

M = Nb)

Inorganic

Synthetic Methods

Some

Conceptual Developments in Synthesis in

Chemistry

16.8

Inorganic

synthetic methods can be classified

roughly according to the

volatility or

solubility

of the component reactants. Soluble

inorganic compounds are

prepared using

the

methods of organic

synthesis.

Techniques

employed in Inorganic

synthesis

Oven

techniques: For

thermally robust materials,

high temperature methods are

often

employed.

For example, bulk solids

are prepared using tubular

furnaces, which allow

reactions

to be conducted up to ca. 1100

�C. Special equipment e.g. ovens

consisting of a

tantalum

tube through which an

electric current is passed, can be

used for even

higher

temperatures

up to 2000 �C.

Melt

methods: If

volatile reactants are involved,

the reactants are often put

in an

ampoule

that is evacuated and then sealed.

The sealed ampoule is then

put in an oven and

given

a certain heat treatment to melt

the reactants together and then

later anneal the

solidified

melt.

Solution

methods: Solvents

are used to prepare solids

by precipitation or by

evaporation.

At

times the solvent is used

hydrothermally, i.e. under

pressure at temperatures higher

than

the normal boiling point. A

variation on this theme is

the use of flux methods,

where

a

salt of relatively low

melting point is added to

the mixture to act as a high

temperature

solvent

in which the desired

reaction can take place.

Gas

reactions: Many

solids react readily with

reactive gases like

chlorine, iodine,

oxygen

etc. Others form adducts

with gases like CO or

ethylene. Such reactions are

often

carried

out in a tube that is open

ended on both sides and

through which the gas is

passed

A

special case of a gas reaction is a

chemical transport reaction

which entails the

reversible

conversion of nonvolatile chemical

compounds into volatile

derivatives. This

method

may also be used as a process

for purification and crystallization of

non-volatile

solids.

These are often carried out

in a sealed ampoule to which a

small amount of a

transport

agent, e.g. iodine is added.

The ampoule is then placed in a

zone oven. This is

essentially

two tube ovens attached to

each other which allows a

temperature gradient to

be

imposed. The volatile derivative

migrates through a sealed, evacuated

glass tube

heated

in a tubular furnace. Elsewhere in

the tube where the

temperature is held at a

different

value, the volatile

derivative reverts to the

parent solid and the

transport agent is

released.

The transport agent is thus

catalytic. The technique

requires that the two

ends of

Synthetic

Strategies in Chemistry

16.9

tube

be maintained at different temperatures.

Such a method can be used to

obtain the

product

in the form of single

crystals suitable for

structure determination by

X-ray

diffraction.

Air

and moisture sensitive

materials:

Many solids are hygroscopic

and/or oxygen

sensitive.

Many halides e.g. are very

'thirsty' and can only be studied in

their anhydrous

form

if they are handled in a

glove box filled with

dry (and/or oxygen-free)

gas, usually

nitrogen.

Synthetic

Methods

A

large variety of inorganic

solid materials has been

prepared in recent years by

traditional

ceramic method, which

involves mixing and grinding

powders of the

constituent

oxides, carbonates and such

compounds and heating them at

high

temperatures

with intermediate grinding

when necessary. The low-temperature

chemical

routes,

however, are of greater interest so as to

have better control of the

structure,

stoichiometry

and phase purity. Noteworthy

chemical methods of synthesis

include the

precursor

method, coprecipitation, combustion

method, the gel method,

topochemical

methods

and high-pressure methods. Some of

the methods are outlined

below.

1.

Ceramic Method

The

most common method of

preparing solid materials is by

reaction of the

component

materials

in the solid state at

elevated temperatures. Several

oxides, sulphides,

phosphides,

have been prepared by this

method. Knowledge of the

phase diagram is

generally

helpful in fixing the

desired composition and conditions

for synthesis.

Platinum,

silica and alumina containers

are generally used for

the synthesis of

metal

oxides,

while graphite containers

are employed for sulphides

and other chalcogenides as

well

as pnictides. If one of the constituents

is volatile or sensitive to the

atmosphere, the

reaction

is carried out in sealed evacuated

capsules. Most ceramic preparations

require

relatively

high temperatures which are

generally attained by resistance

heating. Electric

arc

and skull techniques give temperatures up

to 3300 K while high- power

CO2 lasers

give

temperatures up to 4300 K.

The

ceramic method suffers from

several disadvantages. They are:

1.

When no melt is formed

during the reaction, the

entire reaction has to occur

in

the

solid state, initially by a

phase boundary reaction at

the points of contact

between the

Some

Conceptual Developments in Synthesis in

Chemistry

16.10

components

and later by diffusion of the

constituents through the

product phase. As the

reaction

progresses, diffusion paths become

increasingly longer and the

reaction rate

slower.

The product interface

between the reacting

particles acts as a barrier.

The reaction

can

be speeded up to some extent by

intermittent grinding between

heating cycles.

2.

There is no simple way of

monitoring the progress of

the reaction in the

ceramic

method. It is only by trial and

error (by carrying out

X-ray diffraction and

other

measurements

periodically) that one decides on

appropriate conditions that lead

to

completion

of the reaction. Because of

this difficulty, one frequently

ends up with

mixtures

of reactants and products.

3.

Separation of the desired product

from these mixtures is

generally difficult, if

not

impossible.

4.

It is sometimes difficult to obtain a

compositionally homogeneous product

by

the

ceramic technique, even when

the reaction proceeds almost

to completion.

In

spite of such limitations, ceramic

techniques have been widely

used for the

synthesis

of solid materials. Mention

must be made, among others,

of the use of this

technique

for the synthesis of rare

earth mono-chalcogenides such as

SmS and SmSe. The

method

involves heating the

elements, first at lower temperatures

(870-1170 K) in

evacuated

silica tubes; the contents

are then homogenized, sealed

in tantalum tubes and

heated

to around 2300 K.

Various

modifications of the ceramic

technique have been employed

to overcome

some

of the limitations. One of

these relates to decreasing the diffusion

path lengths. In a

polycrystalline

mixture of reactants, the individual

particles are approximately 10 m

in

size,

representing diffusion distances of

roughly 10,000 unit cells. By

using freeze-

drying,

spray-drying, coprecipitation, and

sol-gel and other techniques, it is

possible to

reduce

the particle size to a few

hundred �ngstr�ms and thus

effect a more

intimate

mixing

of the reactants.

In

spray-drying, suitable constituents

dissolved in a solvent are sprayed in

the form of

fine

droplets into a hot chamber.

The solvent evaporates

instantaneously, leaving

behind

an

intimate mixture of reactants, which on

heating at elevated temperatures gives

the

product.

Synthetic

Strategies in Chemistry

16.11

In

freeze-drying, reactants in a common

solvent are frozen by

immersing in liquid

nitrogen

and the solvent is removed at

low pressures.

In

coprecipitation, the required

metal cations taken as

soluble salts (e.g. nitrates)

are

coprecipitated

from a common medium,

usually as hydroxides, carbonates,

oxalates,

formats

or citrates. In actual practice, one

takes oxides or carbonates of

the relevant

metals,

digests them with an acid

(usually HNO3)

and then the precipitating reagent

is

added.

After filtering the

precipitate and drying, it is heated to

the required temperature

in

a

desired atmosphere to produce the

final product. For example,

tetraethylammonium

oxalate

has been used to prepare

superconducting YBa2Cu408.

The decomposition

temperatures

of the precipitates are generally

lower than the temperatures

employed in

the

ceramic method.

2.

Combustion Method

Combustion

synthesis or self-propagating

high-temperature synthesis makes

use of a

highly

exothermic reaction between

the reactants to produce a flame due to

spontaneous

combustion

which then yields the

desired product or its

precursor in finely divided

form.

Borides,

carbides, oxides, chalcogenides and other

metal derivatives have been

prepared

by

this method. In order for

combustion to occur, one has to ensure

that the initial

mixture

of reactants is highly dispersed and has

high chemical energy. For

example, one

may

add a fuel and an oxidizer

when preparing oxides by the

combustion method,

both

these

additives being removed

during combustion to yield

only the product or

its

precursor.

Thus, one can take a mixture of nitrates

(oxidizer) of the desired

metals along

with

a fuel (e.g. hydrazine,

glycine or urea) in solution, evaporate

the solution to

dryness

and

heat the resulting solid to

around 423 K to obtain spontaneous

combustion, yielding

an

oxidic product in fine

particulate form. Even if

the desired product is not

formed

immediately

after combustion, the fine

particulate nature of the

product facilitates

its

formation

on further heating. In order to

carry out combustion

synthesis, the

powdered

mixture

of reactants (0.1-100 m particle size) is

generally placed in an appropriate

gas

medium

which favours an exothermic

reaction on ignition. The

combustion temperature

is

anywhere between 1500 and 3500 K,

depending on the reaction.

The advantages of

this

method

are that

Some

Conceptual Developments in Synthesis in

Chemistry

16.12

reaction

times are very short since

the desired product results

soon after the

�

combustion.

a

gas medium is not always

necessary.

�

This

is so in the synthesis of borides,

silicides and carbides where

the elements are

quite

stable

at high temperatures. Combustion in a

nitrogen atmosphere yields nitrides.

Nitrides

of

various metals have been

prepared in this manner.

Azides have been used as

sources of

nitrogen.

The following are some

typical combustion

reactions:

MoSi2 +

7MgO

MoO3 +

2SiO2

+

7Mg

WC

+ Al2O3

WO3 + C +

2Al

TiB2 +

5MgO

TiO2 +

B2O3

+

5Mg

N2

N2

TaN

Ta2N

Ta

after

burning

Most

of the ternary or quaternary

oxides can also be prepared by this

method. All the

superconducting

cuprates have been prepared by

this method, although the

resulting

products

in fine particulate form

have to be heated to an appropriate high

temperature in a

desired

atmosphere to obtain the final

cuprate. Table 16.1 lists

typical materials

prepared

by

the combustion

method.

Synthetic

Strategies in Chemistry

16.13

Table

1. Typical materials prepared by

the Combustion method

Oxides

BaTiO3,

LiNbO3,

PbMoO4

Carbides

TiC,

Mo2C,

NbC

Borides

TiB2,

CrB2,

MoB2,

FeB

MoSi2,

TiSi2,

ZrSi2

Silicides

Phosphides

NbP,

MnP, TiP

WS2, MoS2, MoSe2,

TaS2

Chalcogenides

Hydrides

TiH2, NdH2

3.

Precursor Method

Synthesis

of complex oxides by the

decomposition of compound precursors

has been

known

for some time. For

example, thermal decomposition of

LaCo(CN)6.5H20

and

LaFe(CN)6.6H20 in air

readily yields LaCoO3 and

LaFeO3

respectively.

BaTiO3

can be

prepared

by the thermal decomposition of

Ba[TiO(C204)2],

while LiCrO2

can be

prepared

from

Li[Cr(C2O4)2(H20)2].

Ferrite spinels of the

general formula MFe204

(M-Mg, Mn,

Ni,

Co)

are prepared by the thermal

decomposition of acetate precursors of

the type

M3Fe6(CH3COO)1703OH.12C5H5N.

Chromites of type MCr204

are

obtained by the

decomposition

of (NH4)2M(CrO4)2.6H20. Carbonates of

metals such as

calcium,

magnesium,

manganese, iron, cobalt,

zinc and cadmium are all

iso-structural, possessing

the

calcite structure. We can therefore

prepare a large number of carbonate

solid solutions

containing

two or more cations in

different proportions.

Carbonate

solid solutions are ideal

precursors for the synthesis of

monoxide solid

solutions

of rock-salt structure. The

facile formation of rock-salt

oxides by the

decomposition

of carbonates of calcite structure is due

to the close (possible

topotactic)

relationship

between the structures of

calcite and rock-salt. The

monoxide solid

solutions

can

be used as precursors for

preparing spinels and other

complex oxides.

Besides

monoxide

solid solutions, a number of

ternary and quaternary oxides of

novel structures

16.14

Some

Conceptual Developments in Synthesis in

Chemistry

can

be prepared by decomposing carbonate

precursors containing the

different cations in

the

required proportions. A number of

ternary and quaternary metal

oxides of perovskite

and

related structures can be prepared by

employing hydroxide, nitrate and

cyanide solid

solution

precursors as well.

4.

Topochemical Reactions

A

solid state reaction is said

to be topochemically controlled when

the reactivity is

controlled

by the crystal structure

rather than by the chemical

nature of the

constituents.

The

products obtained in many

solid state decompositions

are determined by

topochemical

factors, especially when the

reaction occurs within the

solid without the

separation

of a new phase. In topotactic

solid state reactions, the

atomic arrangement in

the

reactant crystal remains

largely unaffected during

the course of the reaction,

except

for

changes in dimension in one or more

directions. Dehydration of WO3.H20

or

MoO3.H20 to

give WO3

or

MoO3

is one such

reaction. Dehydration of many

other

hydrates

such as VOPO4.2H20

and HMoO2PO4.H20 is also

found to be topotactic.

Intercalation

reactions are generally

topotactic in nature. Decomposition of

V2O5

to

form

V6O13

is a similar

reaction. The reduction of

NiO to nickel metal

proceeds

topochemically.

a)Dehydration

of Mo1_xWxO3.H2O

Mo1_xWxO3 solid solutions can be

prepared by the ceramic

method (by heating

MoO3

and

WO3 in

sealed tubes at around 870 K) or by the

thermal decomposition of

mixed

ammonium

metallates. These methods, however, do

not always yield

monophasic

products

owing to the difference in

volatilities of MoO3 and WO3.

Therefore, it was

sought

to prepare Mo1_xWxO3

by

topochemical dehydration of the

hydrates, the process

being

very gentle. MoO3.H2O and

WO3.H2O

are isostructural and the

solid solutions

between

the two hydrates are

prepared readily by adding a

solution of MoO3 and WO3

in

ammonia

to hot 6M HNO3. The hydrates Mo1_xWxO3.H2O

crystallize in the

same

structure

as MoO3.H2O and

WO3.H2O

with a monoclinic unit cell.

The hydrate solid

solutions

undergo dehydration under

mild conditions (around 500 K)

yielding

Mo1_xWxO3

which

crystallizes in the ReO3-related structure of WO3. The ReO3 structure

of

MoO3 is metastable and is produced only by

topotactic dehydration under

mild

conditions.

This preparation of

ReO3-1ike MoO3 by

mild chemical processing is

Synthetic

Strategies in Chemistry

16.15

significant.

Bulk quantities of MoO3 in

the ReO3

structure

have been prepared by

mild

dehydration

of the hydrate.

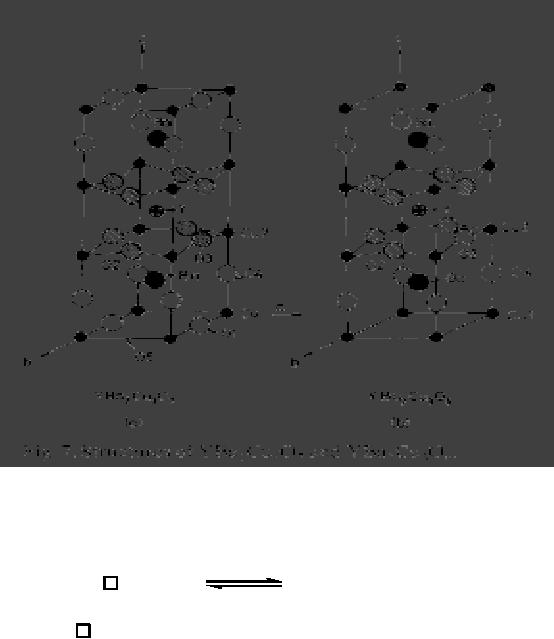

b)Reduction

of perovskite oxides

Reduction

of the high temperature

superconductor YBa2Cu307 to YBa2CuO6 (Fig. 16.7) is

a

topochemical process.

5.

Intercalation Compounds

Intercalation

reactions of solids involve the

insertion of a guest species (ion or

molecule)

into

a solid host lattice without

any major rearrangement of

the solid structure:

x[host]

(guest)x[host]

x(guest)

+

stands

for a vacant lattice

site.

where

Tungsten

and molybdenum bronzes, AxWO3 and AxMoO3

(A=K,

Rb, Cs) are generally

prepared

by reaction of the alkali

metals with the host

oxide. Electrochemical

methods

are

also employed for these

preparations. A novel reaction

that has been employed

to

prepare

bronzes which are otherwise

difficult to obtain involves

the reaction of oxide

host

with

anhydrous alkali

iodides:

16.16

Some

Conceptual Developments in Synthesis in

Chemistry

Mo1-xWxO3

+

y(AI)

→

Ay.Mo1-xWxO3

+

y/2

I2

Atomic

hydrogen has been inserted

into many binary and ternary

oxides. Recently,

iodine

has

been intercalated into the

superconducting cuprate, Bi2CaSr2Cu2O8,

causing an

expansion

of the c-parameter of the unit

cell, without destroying the

superconductivity.

6.

Sol-gel Method

The

sol-gel method is a wet

chemical method and a multi-step

process involving

both

chemical

and physical processes such as

hydrolysis, polymerization, drying

and

densification.

The name "sol-gel" is given to

the process because of the

distinctive

increase

in viscosity which occurs at a

particular point in the

sequence of steps. A sudden

increase

in viscosity is the common

feature in sol-gel processing, indicating

the onset of

gel

formation. In the sol-gel

process, synthesis of inorganic

oxides is achieved

from

inorganic

or organometallic precursors (generally

metal alkoxides). The

important

features

of the sol-gel techniques

are better homogeneity compared

with the traditional

ceramic

method, high purity, lower

processing temperature, more uniform

phase

distribution

in multicomponent systems, better size and

morphological control,

the

possibility

of preparing new crystalline and

non-crystalline materials, and lastly

easy

preparation

of thin films and coatings.

The sol-gel method is widely

used in ceramic

technology.

The important steps in

sol-gel synthesis are:

Hydrolysis.

The process of hydrolysis

may start with a mixture of

a metal alkoxide and

water

in a solvent (usually alcohol) at

the ambient or a slightly

elevated temperature.

Acid

or base catalysts are added

to speed up the

reaction.

Polymerization.

This step involves

condensation of adjacent molecules

wherein H2O

and

ROH

are eliminated and metal

oxide linkages are formed.

Polymeric networks grow

to

colloidal

dimensions in the liquid

(sol) state.

Gelation.

In this step, the polymeric

networks link up to form a

three-dimensional

network

throughout the liquid. The

system becomes somewhat

rigid, characteristic of a

gel.

The solvent as well as water

and alcohol remain inside

the pores of the

gel.

Aggregation

of smaller polymeric units to

the main network continues

progressively on

aging

the gel.

Synthetic

Strategies in Chemistry

16.17

Drying.

Here, water and alcohol are

removed at a moderate temperature (less

than 470

K),

leaving a hydroxylated metal

oxide with residual organic

content. If the objective

is

to

prepare a high surface area

of aerogel powder with low

bulk density, the solvent

is

removed

supercritically.

Dehydration.

This step is carried out

between 670 and 1070 K to drive off

the organic

residues

and chemically bound water,

yielding a metal oxide with

up to 20%-30%

microporosity.

Densification.

Temperatures in excess of 1270 K are

used to form the dense

oxide

product.

Many

complex metal oxides are

prepared by a modified sol-gel

route without

actually

preparing

metal alkoxides. For

example, a transition metal

salt solution is converted

into

a

gel by the addition of an appropriate

organic reagent. In the case of

cuprate

superconductors,

an equimolar proportion of citric acid is

added to the solution of

metal

nitrates,

followed by ethylene diamine

until the solution attains a

pH of 6-6.5. The blue

sol

is concentrated to obtain the

gel. The xerogel is obtained

by heating at approximately

420

K. The xerogel is decomposed at an

appropriate temperature to obtain

the cuprate.

The

sol-gel technique has been

used to prepare sub-micrometre

metal oxide powders

with

a narrow particle size

distribution and unique particle

shapes (e.g. A12O3,

TiO2,

ZrO2,

Fe2O3). Uniform

SiO2

spheres

have been grown from

aqueous solutions of

colloidal

SiO2.

Small metal clusters (e.g.

nickel, copper, gold) have

been prepared by in

situ

chemical reduction of metal

salts. Metal-ceramic composites

(e.g.Ni-AI2O3,

Pt-ZrO2)

can

also be prepared in this manner. By

employing several variants of

the basic sol-gel

technique,

a number of multicomponent oxide systems

have been prepared. Typical

of

these

are: SiO2-B2O3,

SiO2-TiO2,

SiO2-ZrO2,

SiO2-A12O3, ThO2-UO2

. A variety

of

ternary

and still more complex

oxides have been prepared by

this technique.

Different

types

of cuprate superconductors have also

been prepared by this

method. These include

YBa2Cu307,

YBa2Cu408,

Bi2CaSr2Cu208

and Pb2Sr2Ca

1 -xYxCu3O8.

6.

Alkali Flux Method

The

use of strong alkaline media,

either in the form of solid

fluxes or molten (or

aqueous)

solutions,

has enabled the synthesis of

novel oxides. The alkali

flux method stabilizes

higher

oxidation states of the

metal by providing an oxidizing

atmosphere. Alkali

16.18

Some

Conceptual Developments in Synthesis in

Chemistry

carbonate

fluxes have traditionally

been used to prepare

transition metal oxides such

as

LaNiO3. A good

example of an oxide synthesized in a

strongly alkaline medium is

the

pyrochlore,

Pb2(Ru2-xPbx)O7-y where

Pb is in the 4 + state; this oxide is a

bifunctional

electrocatalyst.

The procedure for

preparation involves bubbling

oxygen through a

solution

of lead and rubidium salts in strong KOH at 320 K.

The so-called

alkaline

hypochlorite

method is used in many instances.

For example, La4NiOl0 was prepared by

bubbling

Cl2 gas through a NaOH

solution of lanthanum and nickel

nitrates.

YBa2Cu408

has

been prepared by using a Na2CO3-K2CO3 flux in a flowing

oxygen

atmosphere.

KOH melt has been used to

prepare superconducting Ba1-xKxBiO3.

7.

Electrochemical Method

Electrochemical

methods have been employed

to advantage for the synthesis of

many

solid

materials. Typical of the

materials prepared in this

manner are metal

borides,

carbides,

silicides, oxides and sulphides.

Vanadate spinels of formula

MV2O4

as well

as

tungsten

bronzes have been prepared

by the electrochemical route.

Tungsten bronzes are

obtained

at the cathode when current is

passed through two inert

electrodes immersed in a

molten

solution of the alkali metal

tungstate, A2WO4 and WO3;

oxygen is liberated at

the

anode.

Blue molybdenum bronzes have

been prepared by fused salt

electrolysis. Mono-

sulphides

of uranium, gadolinium, thorium and

other metals are obtained

from a solution

of

the normal valent metal

sulphide and chloride in an NaC1-KCI

eutectic. LaB6,

is

prepared

by taking La2O3 and B2O3

in an

LiBO2-LiF melt and using

gold electrodes.

Crystalline

transition metal phosphides are

prepared from solutions of

oxides with alkali

metal

phosphates and halides. Superconducting

Bal-xKxBiO3

has

been prepared

electrochemically.

Although

the electrochemical method is

old, the processes involved

in the synthesis

of

various solids are not

entirely understood. Generally one

uses solvents whose

decomposition

potentials are high (e.g.

alkali metal phosphates, borates,

fluorides, etc.).

Changes

in melt composition could

cause limitations in certain

instances.

8.

High Pressure Methods

The

use of high pressures for

solid state synthesis has

become increasingly common

in

recent

years. With the development of

high-pressure technology, commercial

equipment

permitting

simultaneous use of both

high-pressure and high-temperature

conditions has

Synthetic

Strategies in Chemistry

16.19

become

available. For the 1-10

kbar pressure range, the

hydrothermal method is

often

employed.

In this method, the reaction

is carried out either in an open or a

closed system.

In

the open system, the solid

is in direct contact with

the reacting gas (F2,

O2 or N2)

which

also serves as a pressure intensifier. A

gold container is generally

used in this type

of

synthesis. This method has

been used for the

synthesis of transition metal

compounds

such

as RhO2,

PtO2

and Na2NiF6

where

the transition metal is in a

higher oxidation

state.

Hydrothermal

high pressure synthesis

under closed system conditions

has been employed

for

the preparation of higher-valence

metal oxides. An internal

oxidant such as KClO3 is

added

to the reactants, which on decomposition

under reaction conditions

provides the

necessary

oxygen pressure. For example,

pyrochlores of palladium(IV) and

platinum(IV),

Ln2M207,

(Ln = rare earth) have been

prepared by this method (970

K, 3 kbar).

(H30)Zr2(PO4)3

and a family

of zero thermal expansion ceramics

(e.g. Ca0.5Ti2P3O12)

have

also been prepared hydrothermally.

Another good example is the

synthesis of

borates

of aluminium, yttrium and such

metals wherein the sesquioxides

are reacted with

boric

acid. Oxyfluorides have been

prepared in HF medium [75].

Zeolites are

generally

prepared

under hydrothermal conditions in

the presence of alkali. The

alkali, the silica

component

and the source of aluminium are

mixed in appropriate proportions and

heated.

The

reactant mixture forms a

hydrous gel which is then

allowed to crystallize

under

pressure

for several hours to several

weeks between 330 and 470 K. In a

typical

synthesis,

AI2O3.3H20

dissolved in concentrated NaOH

solution (20 N) is mixed

with a

1

N

solution

of

Na2SiO3.9H20

to

obtain

a

gel

(of

composition

2.1Na2O.Al2O3.2.1SiO2.60H2O )

which is then crystallized to

give zeolite A. The Na2O-

SiO2-Al2O3-H2O

system yields a large number

of materials with the

zeolitic framework.

Under

alkaline conditions, aluminium is present

as Al(OH)4 anions. The OH-

ions act as

a

mineralizing catalyst while

the cations present in the reactant

mixture determine the

kinds

of zeolite formed.

Besides

water, some inorganic salts

are also encapsulated in some zeolites.

Several

zeolite

structures are found in the

K2O-SiO2-Al2O3-H2O

system as well. Li2O,

however,

does

not give rise to many

microporous materials. Group IIA

cations yield several

zeolitic

products.

16.20

Some

Conceptual Developments in Synthesis in

Chemistry

Zeolitization

in the presence of organic

bases is useful for

synthesizing silica-rich

zeolites.

Silicalite with a tetrahedral

framework enclosing a three-dimensional

system of

channels

(defined by 10 rings wide

enough to absorb molecules up to

0.6 nm in diameter)

has

been synthesized by the

reaction of tetrapropylammonium (TPA)

hydroxide and a

reactive

form of silica between 370 and 470 K.

The precursor crystals have

the

composition

(TPA)20.48SiO2.H20 and the

organic cation is removed by

chemical reaction

or

thermal decomposition to yield

microporous silicalite which

may be considered to be a

new

polymorph of SiO2.

The clathrasil (silica

analogue of a gas hydrate),

dodecasil-1H, is

prepared

from an aqueous solution of

tetramethoxysilane and N(CH3)4OH;

after the

addition

of aminoadamantane, the solution is treated

hydrothermally under nitrogen

for

four

days at 470 K. The use of template

cations has enabled the

synthesis of a variety of

zeolite

materials. Cations such as

(NMe4)+

fit snugly into the

cages (e.g. sodalite cages

of

sodalite

and SAPO or gmelinite cages of

zeolites omega). Neutral organic amines

have

also

been used (e.g. in the

synthesis of ZSM-5). Many

new microporous

materials,

including

those based on AlPO4 (analogue of SiO2),

gallosilicates and

aluminogerminates

(analogues

of aluminosilicates), have been prepared.

AlPO4-based

materials are

prepared

by

the crystallization of gels formed by

adding an organic template to a

mixture of active

alumina,

H3PO4

and water at a

pH of 5-8 around 470 K. Pressures in

the range 10-150

kbar

are commonly used for

solid-state synthesis. In the

piston-cylinder apparatus

consisting

of a tungsten carbide chamber and a

piston assembly, the sample is

contained

in

a suitable metal capsule surrounded by a

pressure-transducer (pyrophyllite). Pressure

is

generated

by moving the piston through

the blind hole in the

cylinder. A microfurnace

made

of graphite or molybdenum is incorporated

in the design. Pressures up to 50

kbar

and

temperatures up to 1800 K are readily

reached in a volume of 0.1

cm3 using this

design.

In the anvil apparatus, first

designed by Bridgman, the sample is

subjected to

pressure

by simply squeezing it between

two opposed anvils. Although

pressures of

around

200 kbar and temperatures up to 1300 K are

reached in this technique, it is

not

popular

for solid-state synthesis since

only milligram quantities can be

handled. An

extension

of the opposed anvil

principle is the tetrahedral

anvil design, where

four

massively

supported anvils disposed

tetrahedrally ram towards

the centre where

the

sample

is located in a pyrophyllite medium

together with a heating

arrangement. The

Synthetic

Strategies in Chemistry

16.21

multi-anvil

design has been extended to

cubic geometry, where six

anvils act on the

faces

of

a pyrophyllite cube located at the

centre. The belt apparatus

provides the best

high-

pressure-high-temperature

combination for solid-state

synthesis. This apparatus,

which

was

used for the synthesis of

diamonds some years ago is a

combination of the

piston-

cylinder

and the opposed anvil designs.

The apparatus consists of two

conical pistons

made

of tungsten carbide, which ram

through a specially shaped

chamber from opposite

directions.

The chamber and pistons are

laterally supported by several steel

rings making

it

possible routinely to reach fairly high

pressures (around 150 kbar) and

high

temperatures

(approximately 2300 K). In the

belt apparatus, the sample is contained

in a

noble

metal capsule (a BN or MgO container is

used for chalcogenides) and

surrounded

by

pyrophyllite and a graphite sleeve, the

latter serving as an internal

heater. In a typical

high-pressure

run, the sample is loaded, the

pressure raised to the

desired value and

then

the

temperature increased. After holding

the pressure for about 30

min, the sample is

quenched

(400 Ks-1) while still under

pressure. The pressure is released

after the sample

has

cooled at room

temperature.

High-pressure

methods have been used

for the synthesis of several

materials that

cannot

possibly be made otherwise. In

general, the formation of a

new compound from

its

components

requires that the new

composition have a lower

free energy than the

sum of

the

free energies of the

components. Pressure can aid in the

lowering of free energy

in

different

ways.

(a)Pressure

delocalizes outer d electrons in

transition-metal compounds by increasing

the

magnitude

of coupling between the d

electrons on neighbouring cations,

thereby lowering

the

free energy. A typical

example is the synthesis of

ACrO3 (A = Ca, Sr, Pb)

perovskites

and

CrO2.

(b)

Pressure stabilizes higher-valence

states of transition metals,

thus promoting the

formation

of a new phase. For example,

in the Ca-Fe-O system only

CaFeO2.5 (brown-

millerite)

is stable under ambient pressures.

Under high oxygen pressures,

iron is

oxidized

to the 4+ state and hence CaFeO3 with the perovskite

structure is formed.

(c)

Pressure can suppress the

ferroelectric displacement of cations,

thereby adding the

synthesis

of new phases. The synthesis

of A~MoO3 bronzes, for

example, requires

16.22

Some

Conceptual Developments in Synthesis in

Chemistry

populating

the empty d orbitals centred

on molybdenum; at ambient pressures,

MoO3 is

stabilized

by a ferroelectric distortion of

MoO6 octahedra up to the melting

point.

(d)

Pressure alters site-preference

energies of cations, and facilitates

the formation of new

phases.

For example, it is not possible to

synthesize A2+Mn4+O3

(A = Mg,

Co, Zn)

ilmenites

because of the strong

tetrahedral site preference of the

divalent cations. One

therefore

obtains a mixture of A[AMn]O4(spinel)

+ MnO2(rutile) under

atmospheric

pressure

instead of monophasic AMnO3.

However, the latter is

formed at high

pressures

with

a corundum-type structure in which

both the A and Mn ions are

in octahedral

coordination.

(e)

Pressure can suppress the

6s2 core

polarization in oxides containing

isoelectronic

Tl+,

Pb2+, Bi3+

cations.

For example, perovskite-type

PbSnO3 cannot be made at

atmospheric

pressure because the mixture

of PbO + SnO2 is more stable than

the

perovskite.

Thus,

solid-state reactions are

generally slow under

ordinary pressures even when

the

product

is thermodynamically stable. Pressure has

a marked effect on the

kinetics of the

reaction,

reducing the reaction times

considerably, and at the same

time giving more

homogeneous

and crystalline products. For

instance, LnFeO3,

LnRhO3

and

LnNiO3

(Ln

=

rare

earth) are prepared in a

matter of hours under

high-pressure-high-temperatue

conditions,

whereas at ambient pressure the

reactions require several days

(LnFeO3 and

LnRhO3) or

they do not occur at all

(LnNiO3

). Thus

LnFeO3

is formed in

30 min at 50

kbar.

In

several (AX)(ABX3)n series of compounds, the

end members ABX3 and A2BX4,

having

the perovskite and K2NiF4

structures

respectively, are formed at

atmospheric

pressures,

but not the intermediate

phases such as A3B2X7

and A4B3X10.

Pressure

facilitates

the synthesis of such

solids. Sr3Ru2O7

and Sr4Ru3O10

are

formed in 15 min at

20

kbar and 1300 K.

High-pressure

methods

have

been

employed

in

the

synthesis

of

novel

superconducting

cuprates. A rudimentary example is the

preparation of oxygen-excess

La2CuO4

under

high oxygen pressure. A more

interesting example is the

synthesis of the

next

homologue with two

CuO2 layers. La2Cal- xSrxCu2O6

which had

earlier been found

to

be an insulator was rendered superconducting by

heating it under oxygen

pressure.

Synthetic

Strategies in Chemistry

16.23

YBa2Cu408 was first prepared under

high oxygen pressure, but

this was soon found

unnecessary.

However, superconducting cuprates with

infinite CuO2 layers of the

type

Ca1-xSrxCuO2

or Sr1-xNdxCuO2

can only be

prepared under high

hydrostatic pressures

which

help to give materials with

shorter Cu-O bonds. It should be

noted that Ca1-

xSrxCuO2

prepared

at ambient pressure is

insulating.

9.

The pyrosol Process: a novel

chemical method for

depositing films

Pyrolysis

of sprays is a well known method

for depositing films. Thus,

one can obtain

films

of oxidic materials such as

CoO, ZnO and YBa2Cu307 by the spray pyrolysis

of

solutions

containing salts (e.g. nitrates) of

the cations. A novel

improvement in this

technique

is the pyrosol process

involving the transport and subsequent

pyrolysis of a

spray

generated by an ultrasonic atomizer.

When a high frequency (100

kHz-10 MHz

range)

ultrasonic beam is directed at a

gas-liquid interface, a geyser is formed

and the

height

of the geyser is proportional to the

acoustic intensity. Its

formation is accompanied

by

the generation of a spray,

resulting from the

vibrations at the liquid

surface and

cavitation

at the liquid-gas interface.

The quantity of spray is a

function of the

intensity.

Ultrasonic

atomization is accomplished using an

appropriate transducer made of

PZT

located

at the bottom of the liquid

container. A 500-1000 kHz

transducer is generally

adequate.

The atomized spray which

goes up in a column fixed to

the liquid container

is

deposited

onto a suitable solid substrate and

then heat treated to obtain the

film of the

material

concerned. The flow rate of

the spray is controlled by

the flow rate of air or

any

other

gas. The liquid is heated to

some extent, but its

vaporization should be avoided.

The

source

liquid contains the relevant

cations in the form of salts

dissolved in an organic

solvent.

Organometallic compounds are

often used (e.g. acetates,

alkoxides,

acetylacetonates,

etc.). Proper gas flow is

crucial to obtain satisfactory

conditions for a

good

liquid spray.

The

pyrosol process is in some

way between chemical vapour

deposition and spray

pyrolysis,

but the choice of source

compounds for the pyrosol

process is larger than

that

available

for chemical vapour

deposition. Films of a variety of

materials have been

obtained

by the pyrosol method. The

thickness of the films can be

anywhere between a

few

hundred angstroms to a few

micrometres. Films of superconducting

cuprates such as

16.24

Some

Conceptual Developments in Synthesis in

Chemistry

YBa2Cu3O7 have also been prepared by

the pyrosol process. Epitaxy

has been observed

in

films deposited onto

single-crystal substrates.

10.

Czochralski Process for Semiconductor

Materials

Semiconductors

with predictable, reliable

electronic properties are necessary for

mass

production.

The level of chemical purity

needed is extremely high

because the presence

of

impurities even in very

small proportions can have

large effects on the properties

of

the

material. A high degree of

crystalline perfection is also required,

since faults in

crystal

structure (such as dislocations,

twins, and stacking faults)

interfere with the

semiconducting

properties of the material.

Crystalline faults are a

major cause of

defective

semiconductor devices. The larger

the crystal, the more

difficult it is to achieve

the

necessary perfection. Current

mass production processes

use crystal ingots

between

four

and twelve inches (300 mm)

in diameter which are grown

as cylinders and sliced

into

wafers.

Because

of the required level of

chemical purity and the

perfection of the

crystal

structure

which are needed to make

semiconductor devices, special methods

have been

developed

to produce the initial

semiconductor material. A technique

for achieving high

purity

includes growing the crystal

using the Czochralski

process. An additional step

that

can

be used to further increase

purity is known as zone

refining. In zone refining,

part of

a

solid crystal is melted. The

impurities tend to concentrate in

the melted region,

while

the

desired material recrystalizes

leaving the solid material

more pure and with

fewer

crystalline

faults. In manufacturing semiconductor

devices involving heterojunctions

between

different semiconductor materials,

the lattice constant, which

is the length of the

repeating

element of the crystal

structure, is important for

determining the

compatibility

of

materials.

The

Czochralski process is a method of

crystal growth used to

obtain single

crystals

of

semiconductors (e.g. silicon,

germanium and gallium arsenide), metals

(e.g. palladium,

platinum,

silver, gold), salts and some

man-made (or lab) gemstones.

The most important

application

may be the growth of large

cylindrical ingots, or boules, of

single crystal

silicon.

Other semiconductors, such as

gallium arsenide, can also be grown by

this

method,

although lower defect densities in

this case can be obtained

using variants of the

Bridgeman

technique.

Synthetic

Strategies in Chemistry

16.25

High-purity,

semiconductor-grade silicon (only a

few parts per million of impurities)

is

melted

down in a crucible , which is

usually made of quartz.

Dopant impurity atoms

such

as

boron or phosphorus can be added to

the molten intrinsic silicon

in precise amounts in

order

to dope the silicon, thus

changing it into n-type or

p-type extrinsic silicon.

This

influences

the electrical conductivity of

the silicon. A seed crystal,

mounted on a rod, is

dipped

into the molten silicon.

The seed crystal's rod is

pulled upwards and rotated at

the

same

time. By precisely controlling

the temperature gradients, rate of

pulling and speed

of

rotation, it is possible to extract a

large, single-crystal, cylindrical

ingot from the

melt.

Occurrence

of unwanted instabilities in the

melt can be avoided by

investigating and

visualizing

the temperature and velocity

fields during the crystal

growth process [1].

This

process is normally performed in an

inert atmosphere, such as argon, and in

an inert

chamber,

such as quartz.

Size

of Crystals:

While the largest silicon

ingots produced today are

400 mm in diameter

and

1 to 2 metres in length, 200 mm and 300 mm diameter

crystals are standard

industrial

processes.

Thin silicon wafers are

cut from these ingots

(typically about 0.2 - 0.75

mm

thick)

and can be polished to a very high

flatness for making

integrated circuits, or

textured

for making solar

cells.

Impurity

Incorporation:

When silicon is grown by the

Czochralski method the melt

is

contained

in a silica (quartz) crucible.

During growth the walls of

the crucible dissolve

into

the melt and Czochralski

silicon therefore contains

oxygen impurities with a

typical

concentration

of 1018 cm

-3

.

Perhaps surprisingly, oxygen

impurities can have

beneficial

effects.

Carefully chosen annealing conditions can

allow the formation of

oxygen

precipitates.

These have the effect of

trapping unwanted transition

metal impurities in a

process

known as gettering. Additionally,

oxygen impurities can improve

the mechanical

strength

of silicon wafers by immobilising

any dislocations which may

be introduced

during

device processing. It has experimentally

been proved in the 1990s

that the high

oxygen

concentration is also beneficial for

radiation hardness of silicon

particle detectors

used

in harsh radiation environment (

eg. CERN's LHC/S-LHC

projects) [2, 3, 4].

Therefore,

radiation detectors made of Czochralski-

and Magnetic Czochralski-silicon

are

considered

to be promising candidates for

many future high-energy

physics

experiments.[5][6] However,

oxygen impurities can react with

boron in an illuminated

16.26

Some

Conceptual Developments in Synthesis in

Chemistry

environment,

such as experienced by solar cells.

This results in the

formation of an

electrically

active boronoxygen complex

that detracts from cell

performance. Module

output

drops by approximately 3% during the

first few hours of light

exposure [7].

The

Bridgman

technique is

a method of growing single

crystal ingots or boules.

The

method

involves heating polycrystalline

material in a container above its

melting point

and

slowly cooling it from one end

where a seed crystal is

located. Single crystal

material

is

progressively formed along

the length of the container.

The process can be carried

out

in

a horizontal or vertical geometry. It is

a popular method of producing

certain

semiconductor

crystals, such as gallium

arsenide where the

Czochralski process is

more

difficult.

Purification

process: Zone melting is

a method of separation by melting in

which a

molten

zone traverses a long ingot of

impure metal or

chemical.

Zone

refining: In

zone refining, solutes are

segregated at one end of the ingot in

order to

purify

the remainder. The molten

region melts impure solid at

its forward edge and

leaves

a

wake of purer material

solidified behind it as it moves

through the ingot. The

impurities

concentrate

in the melt, and are moved

to one end of the ingot. Zone

refining was

developed

in Bell Telephone Laboratories as a

method to prepare high

purity materials

for

manufacturing transistors. Its

early use was on germanium

for this purpose, but it

can

be

extended to virtually any

solute-solvent system having an

appreciable concentration

difference

between solid and liquid

phases at equilibrium. This

process is also known as

the

Float

zone process,

particularly in semiconductor materials

processing.

Zone

leveling : Zone

melting is also used to concentrate

the impurities for

analytical or

other

purposes. In zone leveling, the

objective is to distribute solute

evenly throughout

the

purified material, which may

be sought in the form of a

single crystal. For

example,

in

the preparation of a transistor or diode

semiconductor, an ingot of germanium is

first

purified

by zone refining. Then a

small amount of antimony is placed in

the molten zone,

which

is passed through the pure

germanium. With the proper

choice of rate of heating

and

other variables, the

antimony can be spread evenly

through the germanium.

This

technique

is also used for the

preparation of silicon for

use in computer

chips.

Heaters:

A

variety of heaters can be used

for zone melting, with

their most important

characteristic

being the ability to form

short molten zones that move

slowly and

Synthetic

Strategies in Chemistry

16.27

uniformly

through the ingot. Induction

coils, ring-wound resistance heaters, or

gas flames

are

common methods. Another

method is to pass an electric

current directly through

the

ingot

while it is in a magnetic field,

with the resulting

magnetomotive force carefully

set

to

be just equal to the weight

in order to hold the liquid

suspended. Zone melting can

be

done

as a batch process, or it can be done

continuously, with fresh

impure material being

continually

added at one end and purer material

being removed from the

other, with

impure

zone melt being removed at

whatever rate is dictated by the

impurity of the feed

stock.

Zone

Remelting: Another related

process is zone remelting, in

which two solutes

are

distributed

through a pure metal. This

is important in the manufacture of

semiconductors,

where

two solutes of opposite conductivity

type are used. For

example, in germanium,

pentavalent

elements of group V such as

antimony and arsenic produce negative

(n-type)

conduction

and the trivalent elements of

group III such as aluminium and

boron produce

positive

(p-type) conduction. By melting a

portion of such an ingot and

slowly refreezing

it,

solutes in the molten region

become distributed to form

the desired n-p and

p-n

junctions.

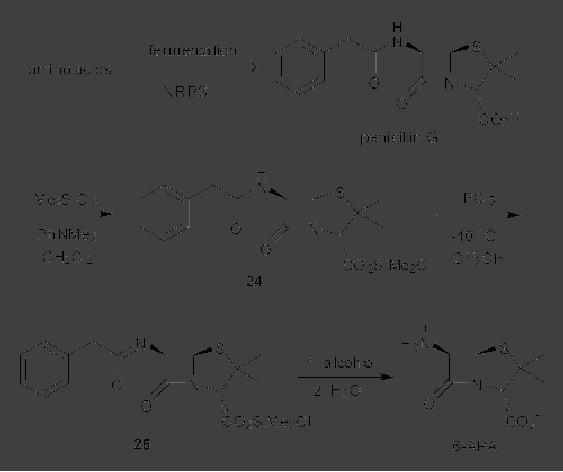

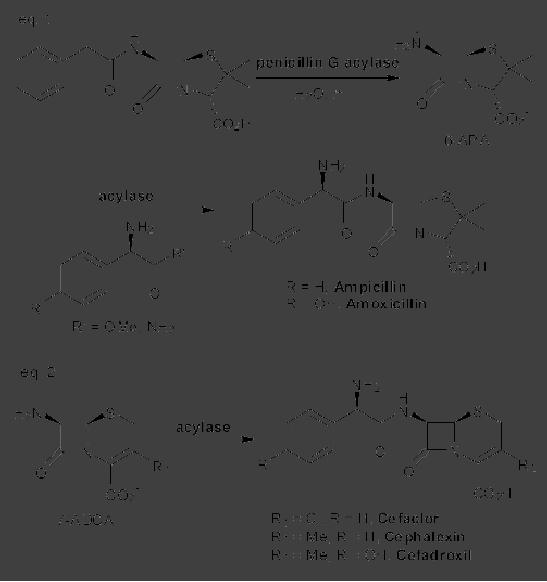

Biocatalysis

Pharmaceutical

industry has been a rapidly

growing field. About 54% of

drug molecules

are

chiral, and resolution remains an

important and cost-effective approach to

chiral

molecules.

In order to achieve a typical

enantiomeric purity of 99.5%,

resolution is often

accomplished

at the price of restricting

the overall maximum yield of

a process to 50% at

most.

While metal catalyzed reactions

have become prevalent in

recent years, their use

in

manufacturing

requires great effort to identify

appropriate catalysts, solvents and

reaction

conditions.

Reproducibility and robustness can remain a

problem, especially with

regard

to

sensitivity to substrate quality and

small variation in reaction parameters.

There is a

clear

need for new methodologies

to produce chiral molecules.

Enzymes are highly

efficient

with excellent regioselectivity and

stereoselectivity. By conducting

reactions in

water

under ambient reaction

conditions, both the use of

organic solvents and

energy

input

are minimized. Furthermore, one can

design processes with high

energy efficiency

and

safe chemistry by conducting

reactions at ambient temperature

under ambient

16.28

Some

Conceptual Developments in Synthesis in

Chemistry

atmosphere,

and atom economy can be increased by

avoiding extensive protection

and

deprotection

sequences.

Biocatalysis

is emerging as one of the greenest

technologies as a result of recent

advances

in

genomics, proteomics and pathway

engineering (large scale DNA

sequencing,

structural

biology, protein expression,

high throughput screening,

directed enzyme

evolution

and metabolic engineering). Application

of the twelve principles of

green

chemistry

can deliver higher efficiency and reduce

the environmental burden

during

chemical

synthesis.

As

the green chemistry movement gains

momentum, fresh opportunities of

research

and

development have been opened

up to improve the efficiency of

chemical processes

while

simultaneously reducing production

costs. The attention is

focused on reducing

the

use

and generation of large quantities of

hazardous substances which

frequently

accompanies

the synthesis of a pharmaceutical

agent, at each of the

numerous steps, each

of

which involve feedstocks, reagents,

solvents, and separation. The following

case

studies

depict the developments and

improvements in the synthetic

strategies of various

chemicals.

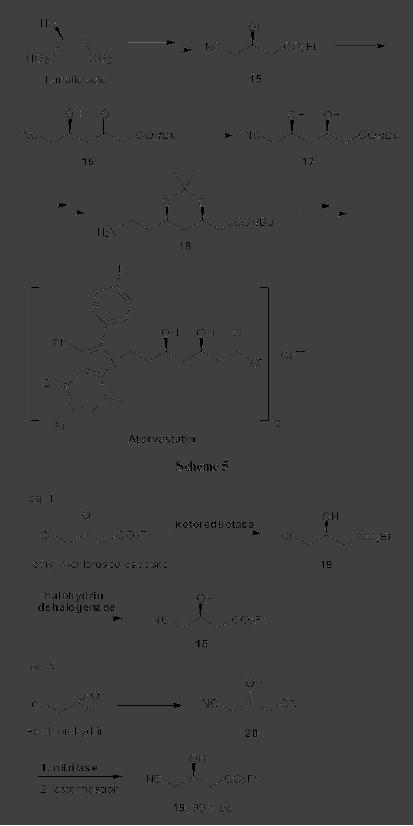

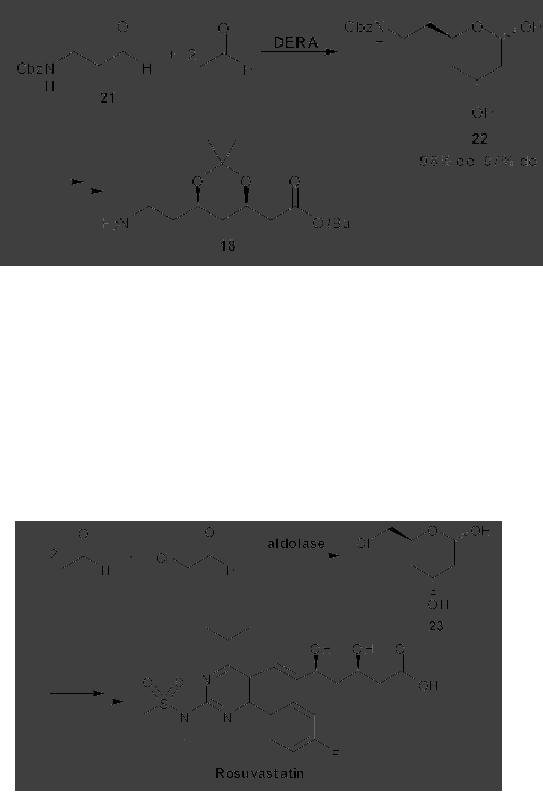

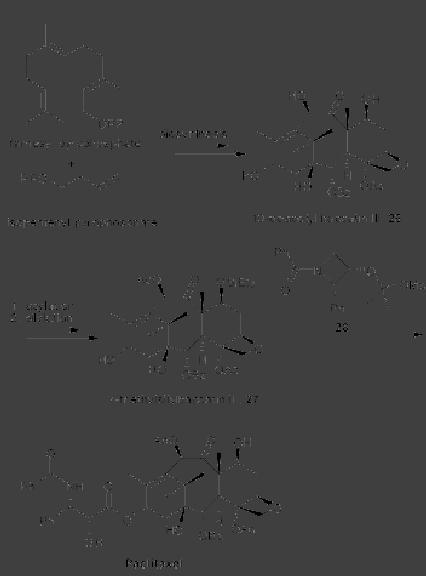

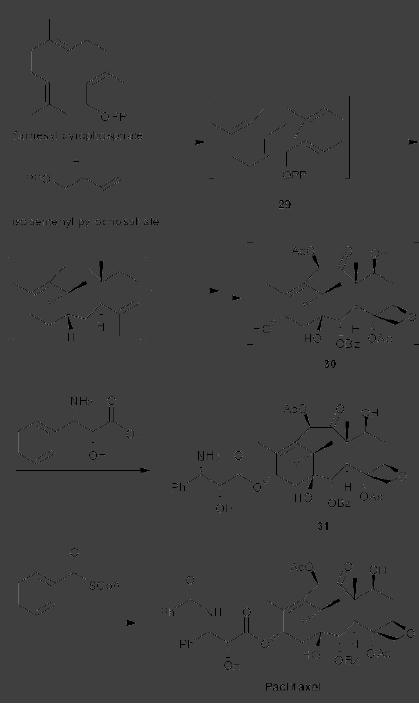

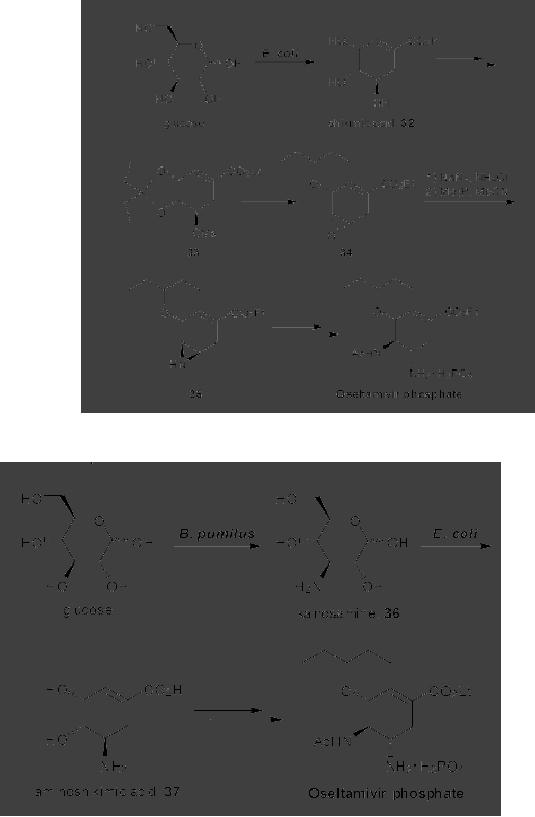

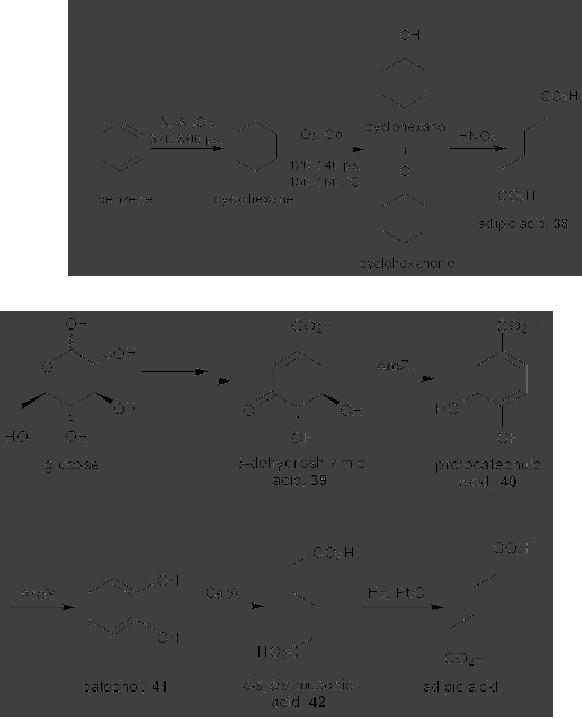

CASE

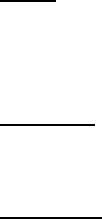

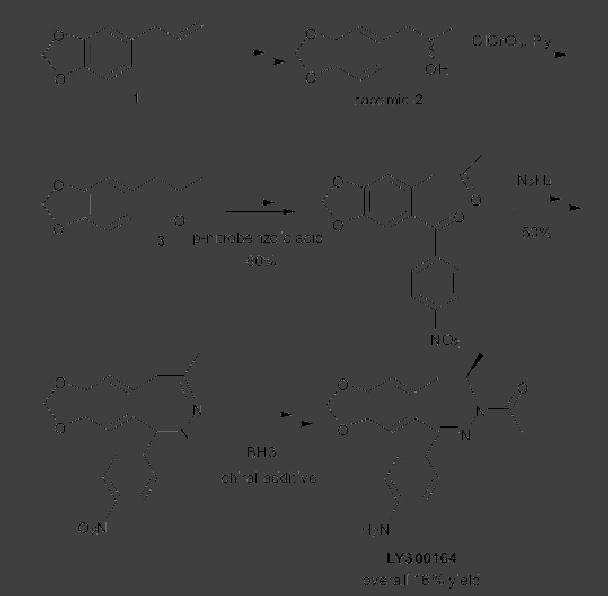

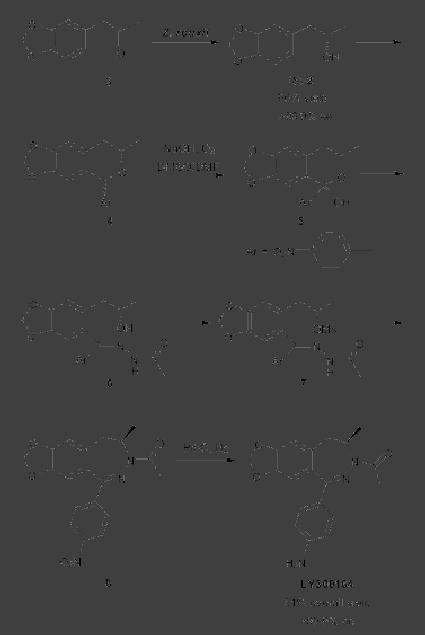

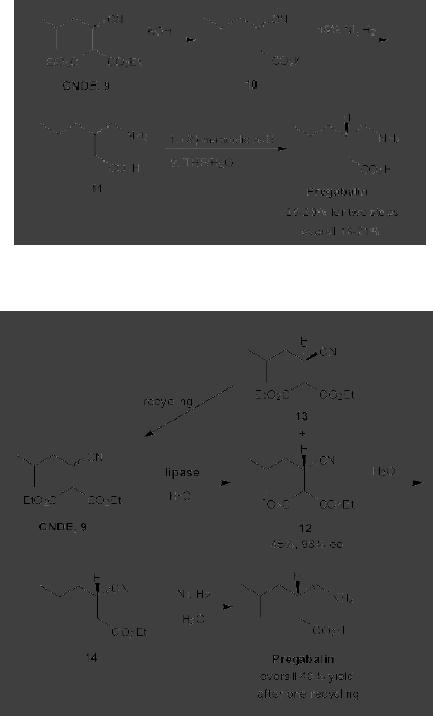

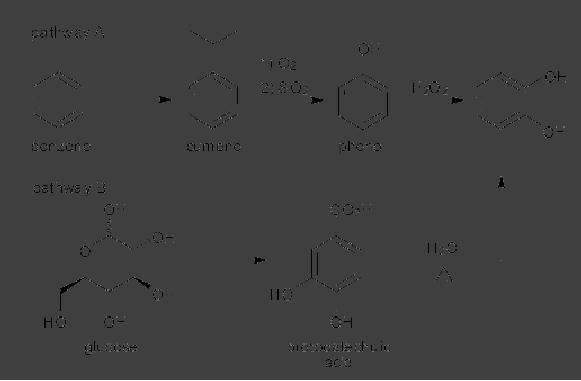

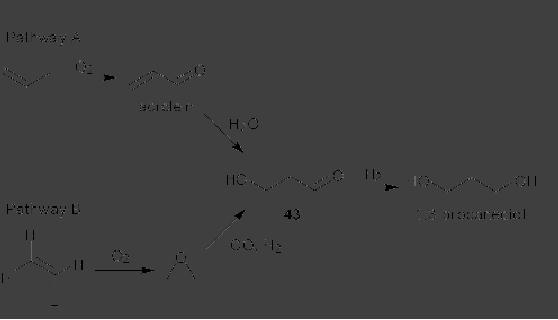

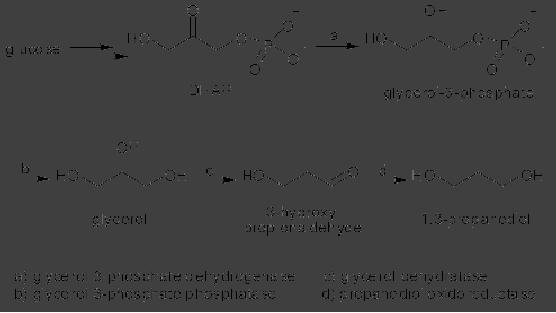

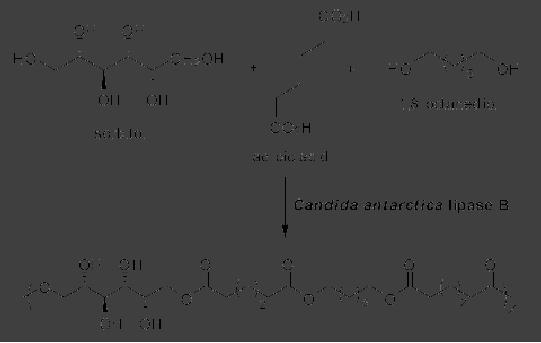

STUDY 1: Production of LY300164

(Talampanol) :

An example of the

reduction

of hazardous materials is the

use of a chemoenzymatic synthesis

for the

production

of LY300164 (Talampanol) for

treating epilepsy and

neurodegenerative

diseases.

The first generation

synthesis, which starts from

5-allyl-1,3-benzodioxole 1,

suffers

from a low yield of 16%, and