|

Production

and Operations Management

MGT613

VU

Lesson

13

We have covered

certain important concepts

like standardization and

mass customization,

through

which

organizations as well as governments are

able to address the requirements of a

broad customer

population.

It is important now to understand how

design strategies are applied and

how to differentiate

between

product and service design. There are

certain common features to both. An

effective operations

manager

should know both about

goods and services. It is also

important to understand that a

good

design

should address the issues

relating to cost, performance and

quality.

DESIGN

STRATEGIES

Design

strategies have one common characteristic, which is to

achieve customer satisfaction, along

with

reasonable

profit in a way which does

not go beyond the organizations

manufacturing abilities. An

exaggerated

example being that if an

automobile car manufacturing

organization's design department

decides

to design a truck. This would

probably mean testing the

organizations manufacturing

capability,

as

the organization would not be have the

infrastructure to manufacture a

truck.

Some

of the common design strategies

are

1.

Design for Manufacturing

(DFM):

The

designers' consideration of the

organization's

manufacturing

capabilities when designing a

product. The more general term design

for

operations

encompasses services as well as

manufacturing. Manufacturability is the

ease of

fabrication

and/or assembly which is

important for:

i.

Cost

ii.

Productivity

iii.

Quality

2.

Design for Assembly (DFA):

Design focuses on reducing the number of

parts in a product

and

on

assembly methods and

sequence.

3.

Design for Disassembly (DFD):

Design focuses on facilitating the

disassembly in a logical and

an

exact reverse sequential manner to the

assembly methods and

sequence.

4.

Design for Recycling (DFR) :

Design allows and facilitates the

recovery of material of materials

and

components from used products

for reuse. The designers'

consideration of the

organization's

manufacturing capabilities when

designing a product. The more general

term

design

for operations encompasses services as

well as manufacturing.

5.

Design for Remanufacturing:

Using some of the components of the

old products in the

manufacture

of new products. Remanufactured products are

sold at 30 to 50% of the price

of

new

product .e.g. Printers, copiers, cameras,

PCs and Cell/Telephones. This

can be done by

original

equipment manufacturer or a competitor or end

user ( in the latter case

its called

cannibalization)

It

is important now to learn as an

Operations Manager the concept of

Recycling. Recycling is in

simple

words

recovering materials for future

use. The common recycling

reasons are

Cost

savings

Environment

concerns

Environment

regulations

Design

for recycling is a design strategy that

facilitates the recovery of materials and

components of old

products

in the manufacture/assembly of new products. The focus

here is to design components

that

would

allow for disassembly and

reuse or even CANABALIZATION.

Robust

Design

Robust

Design: Design that results

in products or services that can

function over a broad range

of

conditions.

The idea is to have consistent, safe and

reliable operations with no excuse

for environmental

characteristics.

E.g. Automobiles/Products produced for

European conditions may not

perform well in

Pakistan

because of different environmental

conditions. Similarly if you happen to

visit an industrial

53

Production

and Operations Management

MGT613

VU

area,

please make sure that

you have a proper OSHA

standard safety boot available to

you. In Pakistan

certain

automobile manufacturers do not comply

with the safety boot requirements for

all its workers

working

at the assembly plants. A non OSHA

compliant safety boot can

probably cause more harm

resulting

in foot amputation

etc.

Taguchi

Approach To Robust

Design

Genichi

Taguchi, a Japanese Manufacturing

Engineer pioneered and championed the

concept of

reduction

in the variability factor in

manufacturing process. His approach

helped manufacturing

organizations

to isolate and eliminate

waste. This approach resulted in quality

improvement and cost

reduction.

With

the aid of the Taguchi Approach we

can determine the factors that

are controllable and those

not

controllable

along with their optimal

levels relative to major

product advances.

The

defining characteristics for the

Taguchi approach include:

Design

a robust product

Insensitive

to environmental factors either in

manufacturing or in use.

Central

feature is Parameter

Design.

An

added concept to Taguchi

Approach is the Degree of Newness. Degree of

newness is an incremental

enhancement

of certain quality based performance

features for the product.

The various ways in

which

degrees

of newness can be achieve

include

1.

Modification of an existing

product/service

2.

Expansion of an existing

product/service

3.

Clone of a competitor's

product/service

4.

New product/service

5.

Degree of Design Change

Phases

in Product Development Process

A

manufacturing organization when

carrying out design of a product

goes through the following

phases.

1.

Idea

generation

2.

Feasibility

analysis

3.

Product

specifications

4.

Process

specifications

5.

Prototype

development

6.

Design

review

7.

Market

test

8.

Product

introduction

9.

Follow-up

evaluation

Idea

Generation often captures

what we have already discussed as

reverse engineering.

Reverse

engineering

is the dismantling and inspecting of a

competitor's product (or any

other manufacturers old

or

existing product) to discover

product improvements.

Research

& Development (R&D) is the organized

efforts to increase scientific

knowledge or product

innovation

& may involve:

Basic

Research advances knowledge

about a subject without near-term expectations

of

commercial

applications.

Applied

Research achieves commercial

applications.

Development

converts results of applied research

into commercial

applications.

54

Production

and Operations Management

MGT613

VU

Concurrent

Engineering

Concurrent

engineering is the bringing together of

engineering design and manufacturing

personnel

early

in the design phase.

Concurrent

Engineering Advantages

Manufacturing

Personnel are able to

identify production capabilities and

capacities .They have

thus

the

opportunity to inform the design group

about the suitability of certain

materials on the flipsides

the

designer would know the suitability of

certain designs in aiding in

cost reduction and

quality

improvement

in production/assembly process.

Early

opportunities for design or procurement of

critical tooling, some of

which might have long

lead

times. This can result in a

major shortening of the product

development process, which

should

be

a key competitive advantage.

Early

consideration of the Technical

Feasibility of a particular design or a

portion of a design. Again

this

can avoid serious problems

during production. The

emphasis can be on problem

resolution

instead

of conflict resolution.

Concurrent

Engineering Disadvantages

Long

standing existing boundaries between design and

manufacturing can be difficult

to

overcome.

Simply bringing a group of

people together and thinking

that they will be able

to

work

together effectively is probably

naÔve.

There

must be extra communication and

flexibility if the process is to work,

and these can be

difficult

to achieve.

Computer-Aided

Design

Computer-Aided

Design (CAD) is product design

using computer graphics.

increases

productivity of designers, 3 to 10

times

creates

a database for manufacturing

information on product

specifications

provides

possibility of engineering and cost

analysis on proposed designs

Modular

Design

Modular

design is a form of standardization in

which component parts are

subdivided into modules

that

are

easily replaced or interchanged. It

allows:

Easier

diagnosis and remedy of failures

Easier

repair and replacement

Simplification

of manufacturing and assembly

A

concept idolized in the IT industry

for software

development

Service

Design

Service

is an act and service delivery system

focuses on facilities, processes and

skills.

Many

services are bundled with

products, like oil change

would require you to pay

for the oil canister as

well.

A good service design involves

The

physical resources needed

which are somewhat Explicit

Services

The

goods that are purchased or

consumed by the customer which

are the services that

we

call

the implicit services

Operations

Manager should be aware of the

fact that service is something

that is done to or for a

customer

and service delivery system

are the required facilities,

processes, and skills needed to

provide

a

service, also the words used are

product bundle and service package. We

should know that the

product

bundle

is the combination of goods and services

provided to a customer and service

package is the

physical

resources needed to perform the

service

55

Production

and Operations Management

MGT613

VU

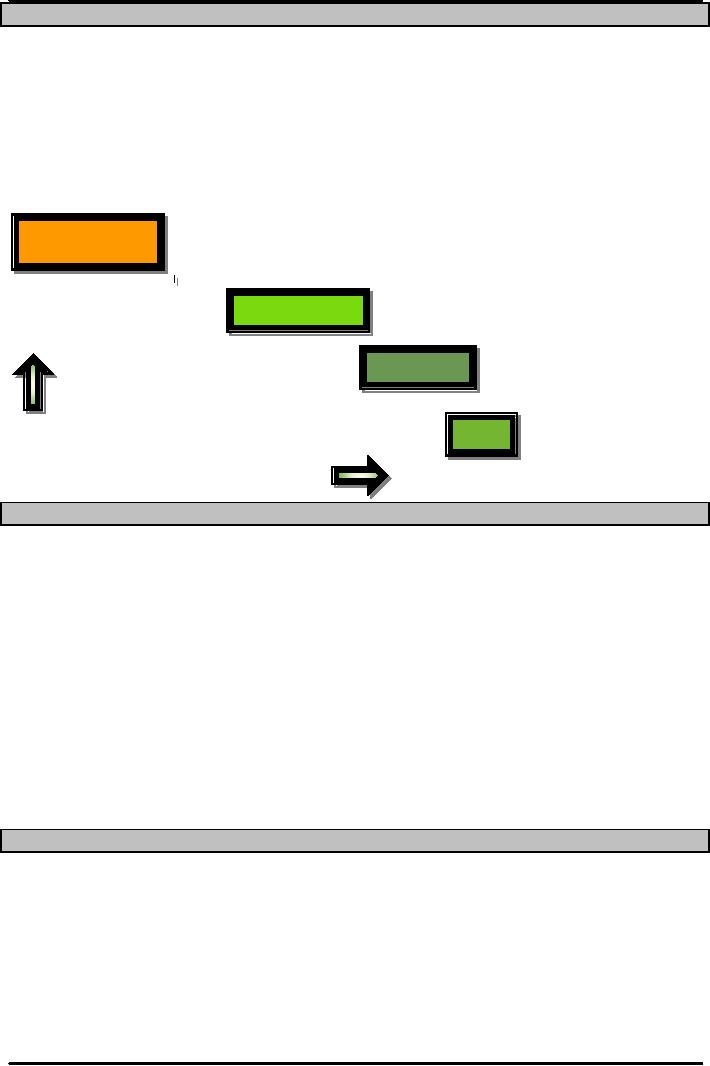

Good

Service Spectrum

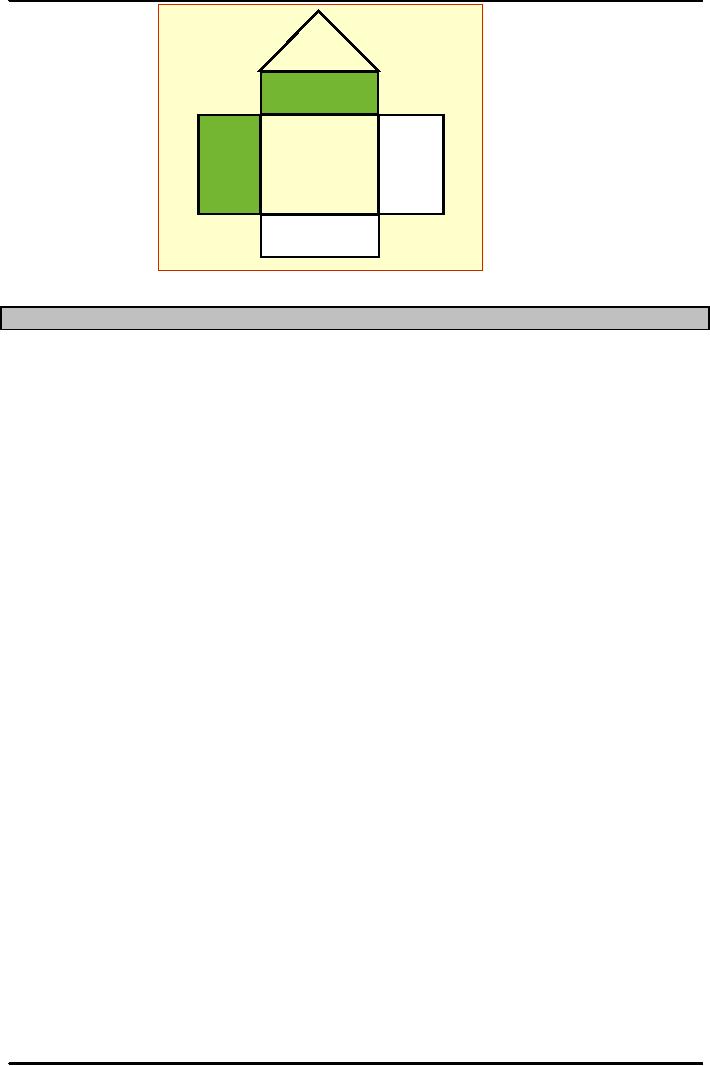

Operations

Managers often end up

answering whether a certain

activity falls under

product

manufacturing

or service development. The figure

below tries to capture the concept of the

whole

spectrum/band

of Goods and Services. The

spectrum or band has on Y axis the

control on goods and on

X

axis the control on

services.

This

is to help understand how a purely

manufacturing organization would

handle a services

assignment

as

well as how the operations manager

would effectively handle

both products as well as

services.

Steel

Production

Automobile

Manufacturing

Auto/Appliance

Repair

Manual

Car Wash

Teaching

Increasing

Increasing

Goods

Control

Service

Content

Difference

between Product and Service Design

1.

Products are Tangible and

generally services are

intangible. Services give

peace of mind which

is

again an intangible

thing.

2.

Services are created and

delivered at the same time,

haircut, car wash. Services

like these if not

properly

designed are instantly discovered by the

customers.

3.

Services highly visible to

customers and should be designed with

that in mind. This adds

an

extra

dimension to process design, one that is

absent in product design.

4.

Services cannot be inventoried. This

poses on restriction on flexibility and

leads to an increased

importance

in capacity design.

5.

Location important to service design. In

fact design of services and choice of

location are often

closely

linked.

6.

Services have low barrier to

entry. Some services (Non

Information Technology BASED)

have

lower

barriers to entry and exit.

This places an additional

pressure on service design to be

innovative

and cost effective.

Phases

in Service Design

Service

Design process requires the thorough

understanding of what the service should

be and how it

should

be delivered and that too

with in certain standardized

specifications or requirements.

1.

Conceptualize

2.

Identify

service package components

3.

Determine

performance specifications

4.

Translate

performance specifications into design

specifications

5.

Translate

design specifications into delivery

specifications

56

Production

and Operations Management

MGT613

VU

A

good operations manager should be

able to see the compatibility between

design requirements for a

product

or a service.

Service

Blueprinting

Service

blueprinting is a method used in service design to

describe and analyze a proposed service. It is

a

useful tool for

conceptualizing a service delivery

system

Major

Steps in Service Blueprinting

1.

Establish boundaries and decide on the level of detail

that is needed.

2.

Identify steps involved and

describe them. If there is an existing

process, get an input

from

those

who do it.

3.

Prepare a flowchart of major

process steps.

4.

Identify potential failure

points. Incorporate features

that minimize the chances of

failures.

5.

Establish a time frame for service

execution and estimate of

variability in processing

time

requirements.

Time is a fundamental determinant of

cost, so establishing a time

standard for

service

is important.

6.

Analyze profitability. Customer

waiting time is important,

leading to negative

profitability

Characteristics

of Well Designed Service Systems

A

well designed service system should be

consistent with the organization's

vision as well as mission. It

should

be user friendly, robust, easy to

sustain, cost effective and

should bring value to

customers.

A

good and well design should

create an effective linkage between back

operations and front

operations.

It should aim for a single

unifying theme. It should

ensure reliability and high

quality.

An

operations manager often faces

challenge of a poor service design. The

reasons of a poor service

design

include variable requirements, difficult

to describe requirements, high volume of

customer

contact.

These challenges can be overcome easily

with the aid of defining a standardized

requirement

that

would be addressed by the service, make

simpler requirements and handle

only limited number of

customers

at each service station or

outlet.

The

House of Quality

It

makes a lot more sense to

introduce the concept of quality in

product and service design here.

We

already

know a superior product

enjoys a broader customer base

because of its superior

quality.

Similarly

a service is a customer encounter. A

popular managerial view is

that the Quality

Function

should

be deployed at the source or at the design

stage. We also should know

what Quality Function

Deployment

is. Two common answers being

that it is the voice of the customer

(which always sets a

standard

for the service organization to follow)

and the second one being that it

should be in the form of

a

house of quality

57

Production

and Operations Management

MGT613

VU

Correlation

matrix

Design

requirements

Customer

Relationshi

Competitive

require-

assessment

p

ments

Specification

s

or

Conclusion

How

organization can improve

their product or service design is based

purely on how much they

are

willing

to invest in Research & Development(R

&D). Organizations should shift

some emphasis away

from

short term performance to long term Performance. They

should work towards continual

and

gradual

improvements instead of the big bang approach.

This is clearly an example of

Japanese

incremental

modification approach to the contrasting

American philosophy of introducing a

different

model.

Whatever may be the approach, a good

design should aim to provide a

reduced product life

cycle.

58

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMERíS AND PRODUCERíS RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model