|

Production

and Operations Management

MGT613

VU

Lesson

43

PROJECT

MANAGEMENT

Learning

Objectives

After

completing our lectures 43 and 44, we

should be able to understand the

Behavioral aspects of

projects

in terms of project personnel and the

project manager. We should be able to

appreciate the

nature

and importance of work breakdown

structure in Project Management. We

should develop a

working

knowledge of PERT/CPM techniques.

Construct

simple network diagrams and try to

assimilate the kind of information that a

PERT or

CPM

analysis can provide. And last

but not the least we should

be able to analyze networks

with

probabilistic

times and describe activity "crashing"

and solve some problems.

Projects

Projects

are unique, one-time

(temporary) operations designed to accomplish a

specific set of

objectives

in a limited time frame.

This

property of being a temporary and a

one-time venture contrasts

with operations,

which

are permanent or semi-permanent ongoing

functional work to create the

same product or

service

over-and-over again.

The

management of these two

systems is often very

different and requires varying technical

skills

and

philosophy, hence requiring the

development of project

management

Project

Management

Project

Management is the organizing and managing

resources in such a way that

these resources

deliver

all the work required to complete a

project within defined

scope, time, and cost

constraints.

A

project is a temporary and

one-time endeavor undertaken to create a

unique product or service.

Distinguishing

characteristics of Project

Management

1.

How is it different?

Limited

time frame

Narrow

focus, specific objectives

Less

bureaucratic

2.

Why is it used?

Special

needs

Pressures

for new or improves products or

services

3.

Project Management has the

following important key

metrics

Time

Cost

Performance

objectives

Key

Success Factors

What

are the Key Success

Factors.

1.

Top-down commitment

2.

Having a capable project

manager

3.

Having time to plan

4.

Careful tracking and

control

5.

Good communications

Project

Management has certain major

administrative issues, such

as

1.

Executive responsibilities

2.

Project selection

3.

Project manager selection

4.

Organizational structure

196

Production

and Operations Management

MGT613

VU

5.

Organizational alternatives

6.

Manage within functional

unit

7.

Assign a coordinator

8.

Use a matrix organization

with a project leader

Project

Management normally involves the

knowledge of Project management

tools, Work

breakdown

structure, Network diagram, Gantt

charts and Risk

management.

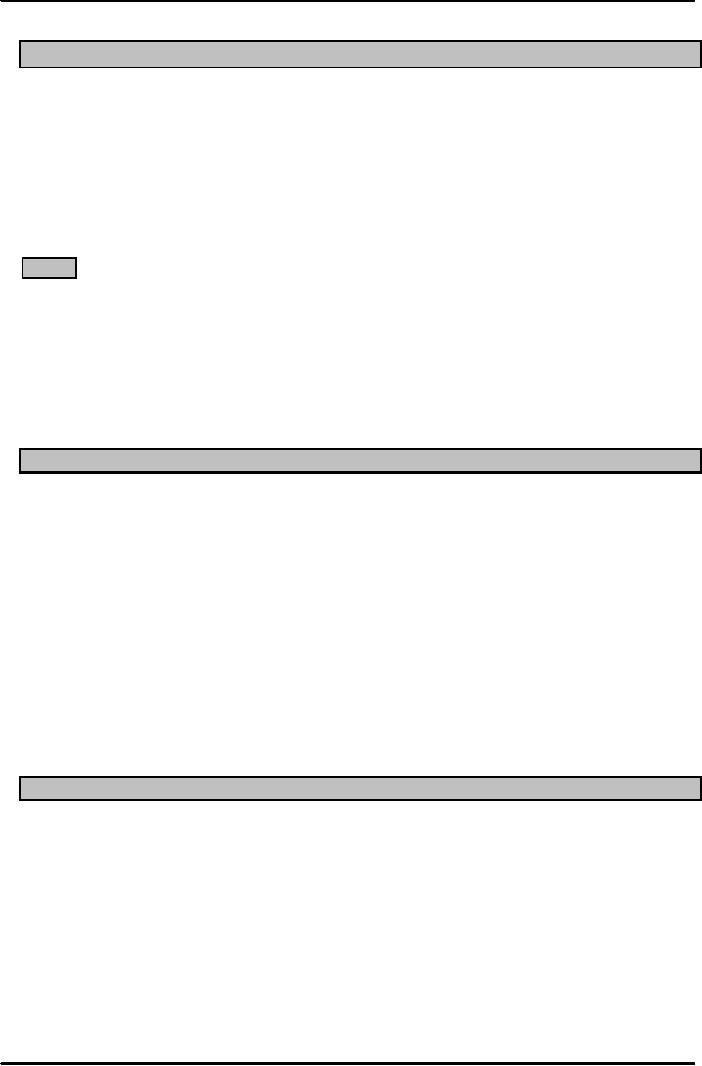

Project

Management: Hospital

We

are given the task of

setting up a hospital facility in

our community. The plan is

to set up both

medicine

and surgery facilities related to all

important fields of medicine and

surgery. The project

Managers

are required to list the possible

activities in the form of

Planning

and Scheduling (Gantt Chart)

and Network Diagram AON and AOA

Activities

M

AP

M

JU

JU

A

SE

O

N

DE

Gantt

chart

A

R

AY

N

L

U

P

CT

O

C

Locate

new facilities

Interview

staff

Hire

and train

staff

Select

and order

Machinery

Remodel

and install

machines

Start

Attending Patient

Project

Management: Hospital Construction and

Operation Activities

include:

Locate

new facilities

Interview

staff

Hire

and train staff

Select

and order Machinery

Remodel

and install phones

Start

Patient Examination/startup

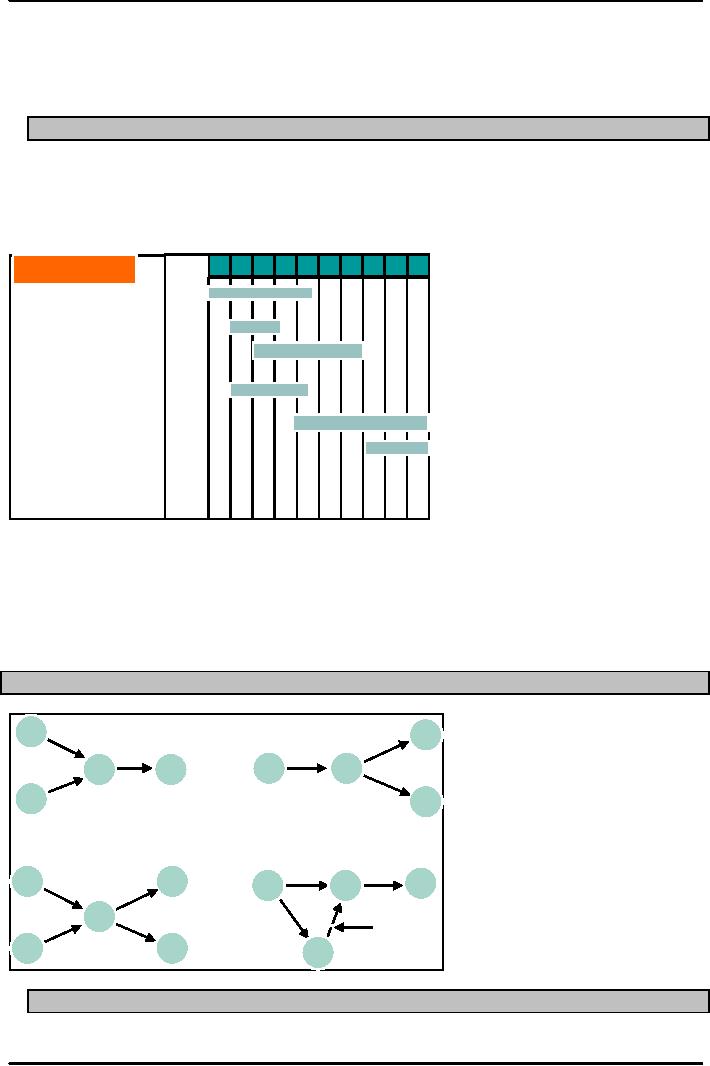

Network

Diagrams and Conventions

a

b

a

c

c

b

a

c

a

c

Dummy

b

activity

b

d

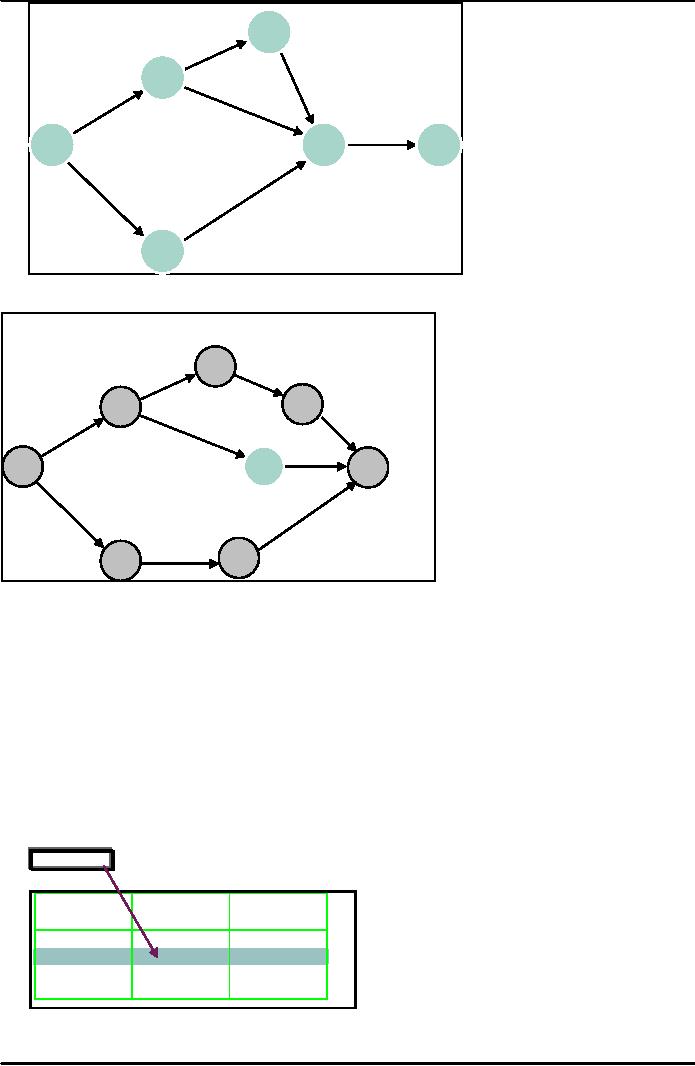

Project

Network Activity on

Arrow

197

Production

and Operations Management

MGT613

VU

Order

4

furnitur

Furniture

2

Locate

setup

facilitie

Remodel

1

5

6

Move

in

Intervie

Hire

and

train

3

Project

Network Activity on

Node

Order

furniture

Furniture

Locate

2

setup

facilities

6

1

Move

Remodel

In

5

S

7

Hire

and

Interview

train

4

3

Activity

on Arrow: The Network

diagram convention in which arrows

designate

activities.

Activity

on Node: The Network diagram

convention in which the nodes

designate

the

activities.

Activities:

Project steps that consume

or utilize resources (and or

time).

Events:

The starting and finishing of

activities designated by nodes in the

Activity

on

Arrow notation.

Path:

Sequence of activities that

leads from the starting node to the

finishing node

Critical

path: The longest path;

determines expected project

duration

Critical

activities: Activities on the critical

path

Slack:

Allowable slippage for path;

the difference the length of path and the

length

of

critical path

Critical

Slack

Path

Length

(weeks)

1-2-3-4-5-6

18

2

1-2-5-6

20

0

1-3-5-6

14

6

198

Production

and Operations Management

MGT613

VU

Project

Life Cycle

The

Project Life Cycle comprises

of a new concept idea for a

unique activity which is

then

evaluated

through feasibility reports, planned

with certain sequence of

activities, execution of

activities

and terminated after the

project has been completed

or shelved due to certain

unavoidable.

What

is important is to note that

all stages of Project Life

Cycle are administered and

handled by

competent

Project Management team or

Project Managers.

M

Feasibilit

A

N

A

Plannin

G

Concep

E

M

E

Executio

N

T

Terminatio

Planning

and Scheduling involves the

following key decisions:

Deciding

which projects to implement

Selecting

a project manager

Selecting

a project team

Planning

and designing the

project

Managing

and controlling project

resources

Deciding

if and when a project should be

terminated

Responsibilities

of a Project Manager

Project

Manager is normally considered responsible

for:

Project

Management

Responsible

for: Technical and Financial

Analysis

Project

Manager is normally considered to have

qualification such as

PMP

certification

CFM,

CFA and CFP

certification

Project

Manager should be skilled

enough to carryout or supervise the

calculation of

Financial

Evaluation and Investment

Analysis

Cost

Benefit Analysis

Project

Managers should be able to focus on

Ethical Issues and

avoid:

Temptation

to understate costs

Withhold

information

Misleading

status reports

Falsifying

records

Compromising

workers' safety

Approving

substandard work

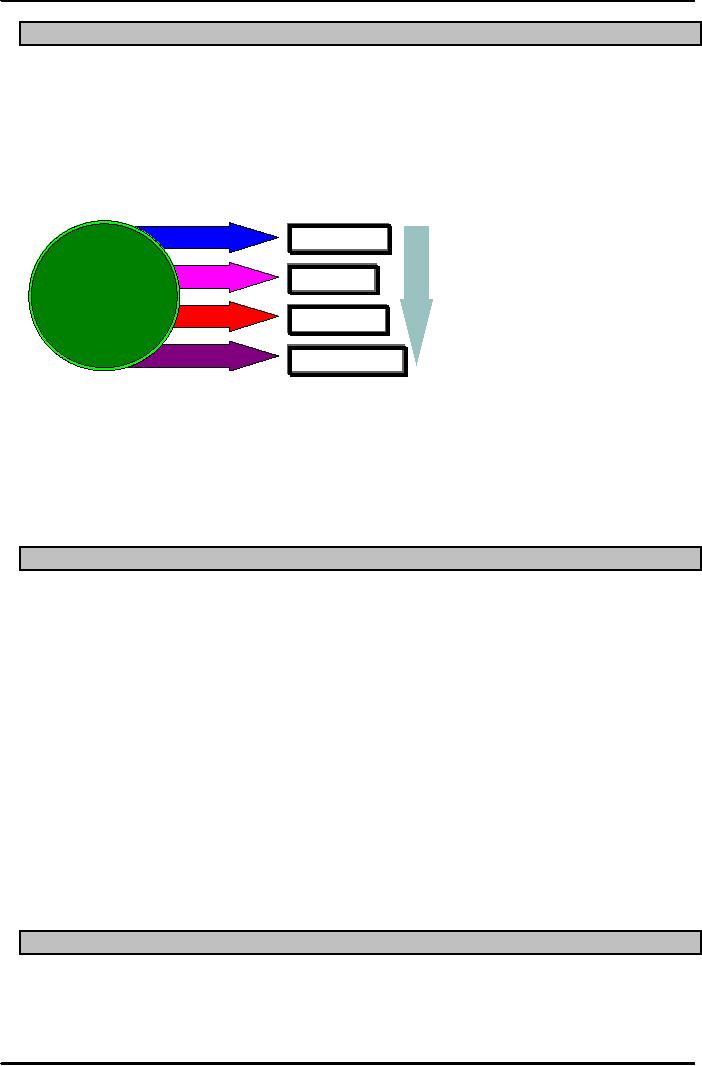

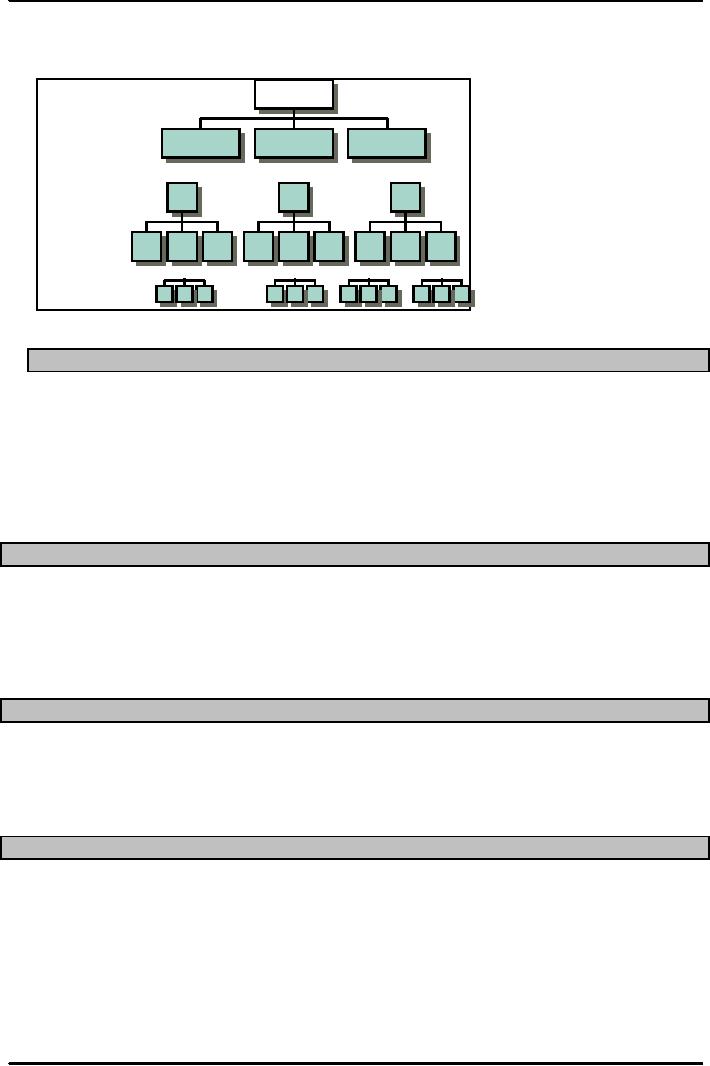

Work

Breakdown Structure

A

project is different that operations due

to its unique nature. A good

project management practice

is

to breakdown the project into

sublevel or group of similar

activities. These sublevel or

group of

similar

activities is called Work

Breakdown Structure.

199

Production

and Operations Management

MGT613

VU

The

work breakdown structure usually

represents a Parent Child

Activity with

the

relationship between a parent and child

level being easily

identifiable. The work break

down

structure

allows a project manager to

incorporate more administrative control

over the project

activities.

Project

Level

1

Level

2

Level

3

Level

4

PERT

and CPM

PERT:

Program

Evaluation and Review

Technique

CPM:

Critical

Path Method

1.

Graphically

displays project

activities

2.

Estimates

how long the project will

take

3.

Indicates

most critical

activities

4.

Show

where delays will not affect

project

Advantages

of PERT

1.

Forces

managers to organize

2.

Provides

graphic display of

activities

3.

Identifies

4.

Critical

activities

5.

Slack

activities

Limitations

of PERT

1.

Important

activities may be

omitted

2.

Precedence

relationships may not be

correct

3.

Estimates

may include a fudge

factor

4.

May

focus solely on critical

path

Project

Scope and Scope Creep

Project

Scope refers to the total work

needed out of a project. The

primary tool required to

describe

Project

Scope is the Work Breakdown Structure.

Often projects suffer from an

irritant known as

scope

creep.

Scope creep is the unnecessary

extension of project scope

which does not allow the

project to be

completed

within budget and with in

the time limits. Organizations

incorporate special management

techniques

to isolate and eliminate

scope creep. Senior

Management is advised and trained by

outside

consultants

to avoid decisions which lead to

increase in business scope

creep or technical scope

creep.

Technical

Scope creep ( like Gold

plating) is the unfortunate tendency of

technical side to add

certain

avoidable

and costly features in their

products ( services or softwares) to make

their product or service

more

powerful and attractable to the

customers. Business Scope

creep (often called customer

pleasing)

200

Production

and Operations Management

MGT613

VU

is

the tendency of the business managers to

over do the customer relationship

with their customers.

A

pragmatic

strategy to avoid scope creep is to be

judicious to the original project

scope and religiously

avoid

uncalled for business or

technical additions that may

incorporate scope

creep.

Summary

We

learnt the Project Management

concept to be different and unique

from operations side. Operations

represent

a repetition of same activities

while projects represent execution of

unique activities.

However

there

exist similarities which

include administration of activities by

project manager in a similar

fashion

to

the activities performed by the operations manager. We

discussed the Network Diagrams, an

Hospital

example

Project in terms of Gantt

Chart, Work Breakdown Structure and

job responsibilities of a

Project

Manager.

201

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMERíS AND PRODUCERíS RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model