|

ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMERíS AND PRODUCERíS RISK |

| << QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart |

| AGGREGATE PLANNING:Demand and Capacity Options >> |

Production

and Operations Management

MGT613

VU

Lesson

28

ACCEPTANCE

SAMPLING

Acceptance

sampling is an important form of

inspection applied to lots or

batches of items before or

after

a process, to judge conformance with

predetermined standards. Similarly

Sampling plans are

the

plans

that specify lot size,

sample size, number of samples,

and acceptance/rejection criteria

Single-sampling

Double-sampling

Multiple-sampling

Single

Sampling Characteristics

One

random is drawn from each

lot.

Every

item in the sample is

examined

Each

item after examination is

classified good or

defective.

If

the sample contains more than a specified

number of defectives say c, then that

lot is

rejected.

Double

Sampling Plan Characteristics

Takes

care of limitation of Single

Sampling Plan by taking another

sample if results of

the

initial

sample are

inconclusive.

If

results from second sample

also indicate poor quality

than the lot is rejected or

otherwise

decision

reached on the basis of both

samples.

A

double sampling plan specifies the

lot size, the size of the

initial sample, accept/reject

criteria

for

the initial sample, the size of the

second sample and a single

acceptance number.

With

double sampling plan, 2 values

are specified for number of

defective items, a lower

level

c1

and an upper level c2. E.g.

if we have c1 equal to 2 and c2 to 7, if number of

defects is

smaller

than c1 than sampling is

terminated and lot is

accepted.

If

defects are greater than c2,

than lot is rejected.

If

its between c1 and c2 then second

sample is selected and compared to a

third value c3 which

can

be 8 and if the cumulative defects

from 1 and 2 does not

exceeds c3, the lot is

accepted.

CHOOSING

A PLAN

Cost

and time are prime determinants of

choosing a plan.

Primary

considerations are number of samples

needed and total number of

observations

required.

Single

sample has only one

sample but large sample

size.

Where

the cost to obtain a sample is

high than cost of analyzing

the sample, single sample

plan

is

followed.

Where

inspection costs are higher

than costs of obtaining the

sample, multiple samples

are

carried

to ensure that a good or bad

result can help terminate

the sample testing thus

ensuring

savings

in inspection cost.

Multiple

Sampling Plans

Similar

to double sampling plan but

allows more than two

samples.

A

sampling plan will specify

each sample size and two

limits for each

sample.

The

values increase with number of

samples.

If

the cumulative number of defects ( in

current and previous samples)

exceed the upper

limit,

then

sampling is terminated and the lot is

rejected.

If

defects les than

permissible, lot is

accepted.

130

Production

and Operations Management

MGT613

VU

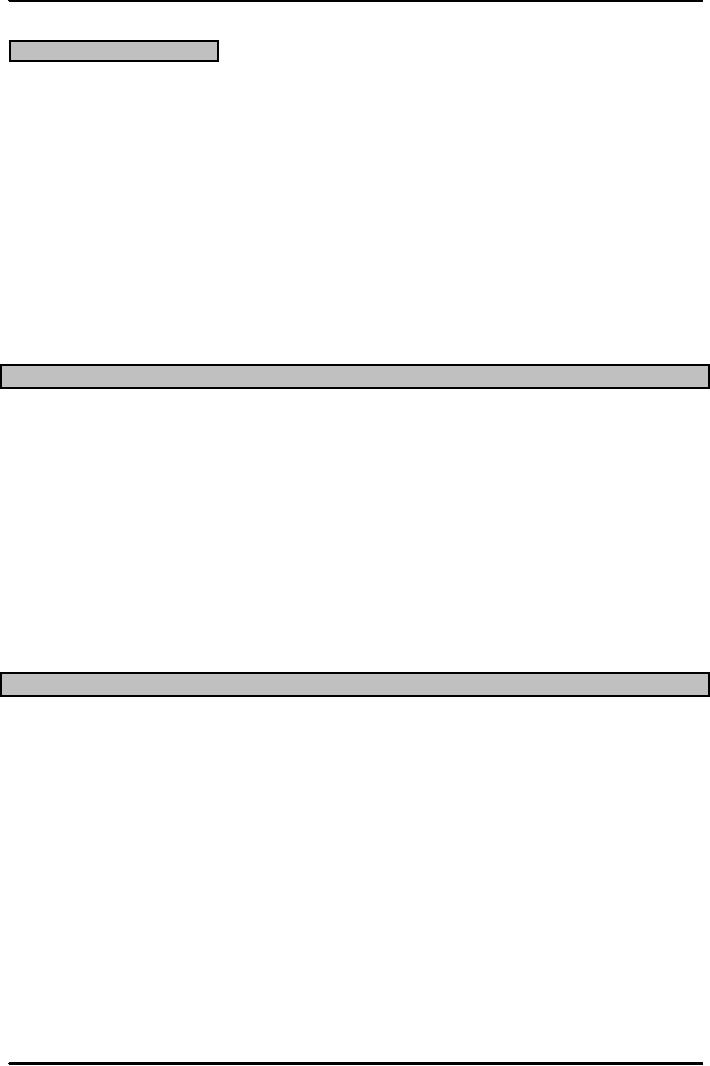

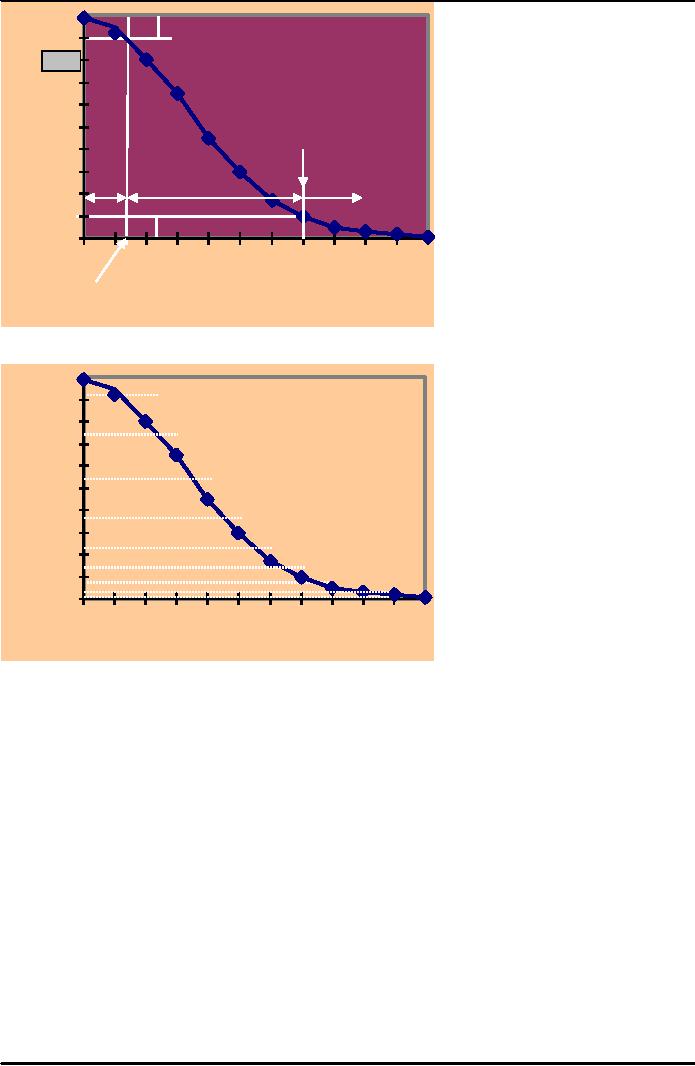

OPERATING

CHARACTERISTIC CURVE

Important

criteria of sampling plan

are how it discriminates between lots of

high and low quality.

The

ability of a Sampling Plan to

discriminate is described by its

OC.

The

degree to which a sampling

plan discriminates between good and bad

lots is a function of

steepness

of the curve

The

ideal plan would require

100 % inspection of each

lot.

OC

Curves

P

100%

R

OC

Curves come in

O

various

shapes

B

depending

on the

A

75%

sample

size and risk of

B

α

and

β

errors

I

L

50%

I

This

curve is more

T

discriminating

Y

O

25%

This

curve is less

F

discriminating

A

C

C

E

.03

.06

.09

P

T

Lot

Quality (Fraction

Defective)

I

N

G

L

O

T

The

Perfect OC Curve

The

Perfect OC Curve

Pr

100%

o

ba

bil

ity

75%

This

curve distinguishes

of

perfectly

between good

A

and

bad lots.

cc

ep

50%

ti

n

What

would allow you

g

to

achieve a curve like

L

25%

this?

ot

.03

.06

.09

Lot

Quality (Fraction

Defective)

OC

Curve Terms

131

Production

and Operations Management

MGT613

VU

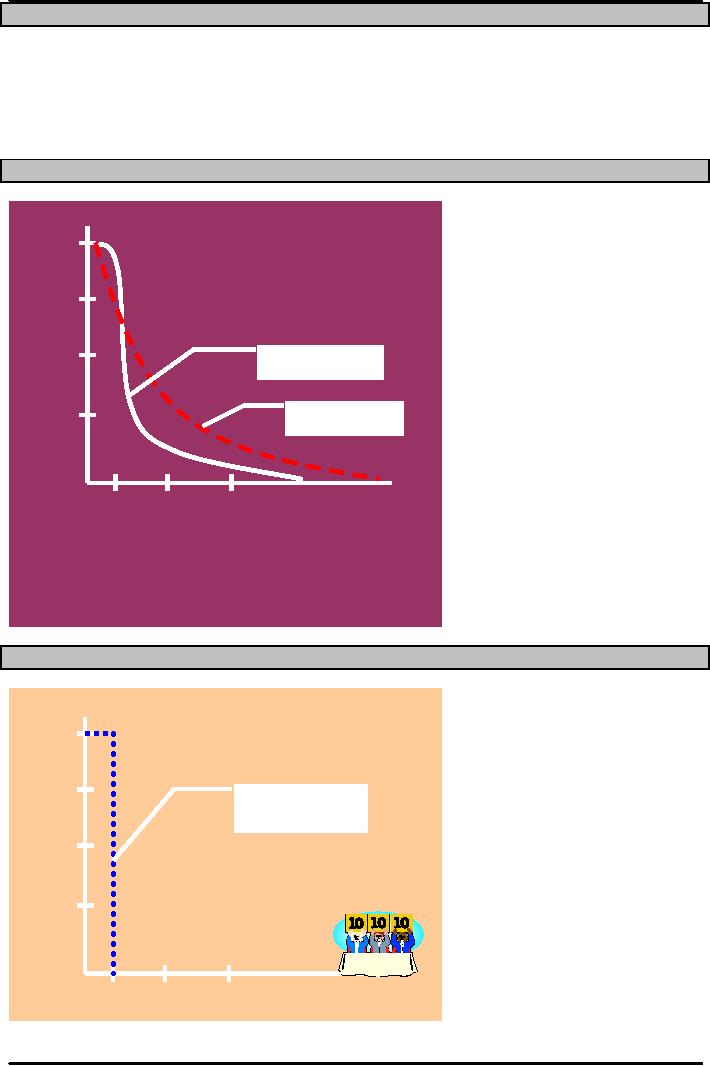

Acceptable

Quality Level (AQL):

Percentage of defective items a customer

is willing to accept

from

you

(a property of mfg.

process)

Lot

Tolerance Percent Defective

(LTPD): Upper limit on the

percentage of defects a customer

is

willing

to accept ( a property of the

consumer)

Average

Outgoing Quality (AOQ):Average of

rejected lots and accepted

lots

Average

Outgoing Quality Limit

(AOQL):Maximum AOQ for a range of

fractions defective

OC

The

curve shows the probability

that use of the sampling

plan will result in lots

with various

fractions

defective

being accepted. The graph

shows that the lot with 3

percent defects ( a fraction of 0.03)

would

have

a probability of about 0.9

being accepted , 90%. And

1-0.9 =0.1 ( 10% being

rejected)

As

the lot quality decreases, the

probability of acceptance decreases,

although the relationship is

not

linear.

OC

Definitions on the Curve

Pr

100%

α

=

0.10

o

90%

ba

bil

ity

75%

of

A

cc

ep

50%

ti

n

g

L

25%

LTPD

ot

AQL

β

=

0.10

Indifferent

Good

Bad

.03

.06

.09

Lot

Quality (Fraction

Defective)

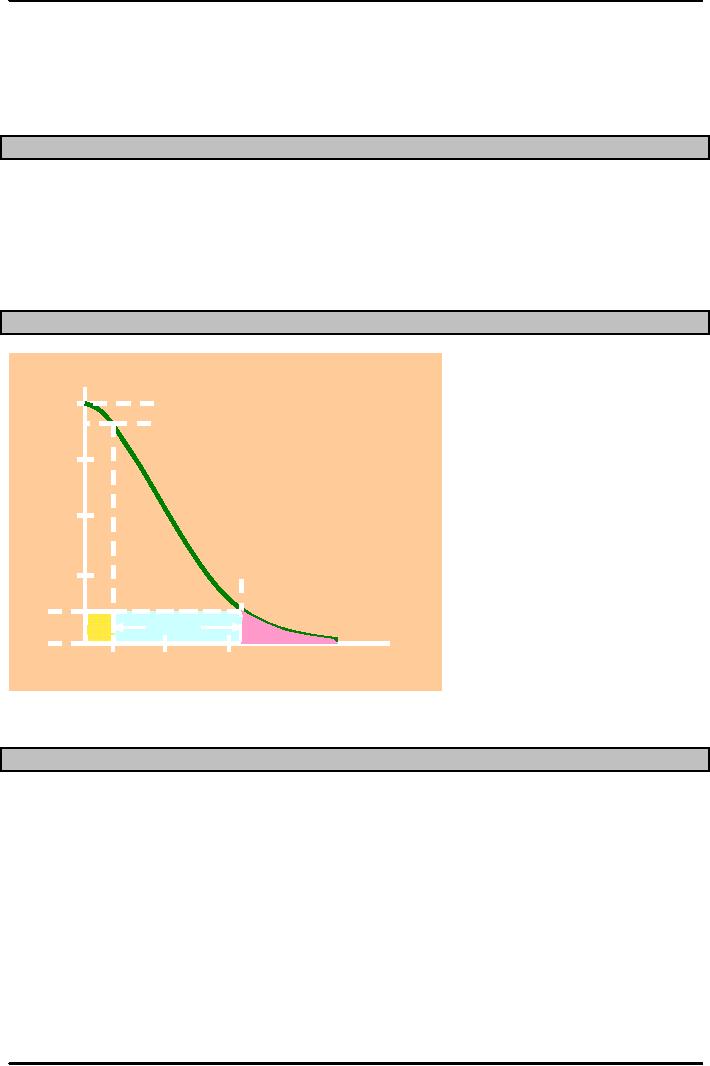

OPERATING

CHARACTERISTIC CURVE

132

Production

and Operations Management

MGT613

VU

1

Pr

0.9

ob

0.8

ab

0.7

ilit

0.6

y

0.5

of

0.4

ac

0.3

ce

0.2

3

0.1

pti

0

ng

0

.05

.10

.15

.20

.25

Lot

quality (fraction

DECISION

CRITERIA

1.00

P

Idea

R

O

B

A

B

I

L

I

Not

very

T

Discriminatin

Y

OF

A

C

C

"Good

"Bad

E

P

T

I

0

N

G

LOT

Lot

quality (fraction

Sampling

Terms

Acceptance

quality level (AQL): the

percentage of defects at which

consumers are willing to

accept

lots

as "good"

Lot

tolerance percent defective (LTPD): the

upper limit on the percentage of

defects that a

consumer

is willing to accept

Consumer's

risk: the probability that a

lot contained defectives

exceeding the LTPD will

be

accepted

Producer's

risk: the probability that a

lot containing the acceptable

quality level will be

rejected

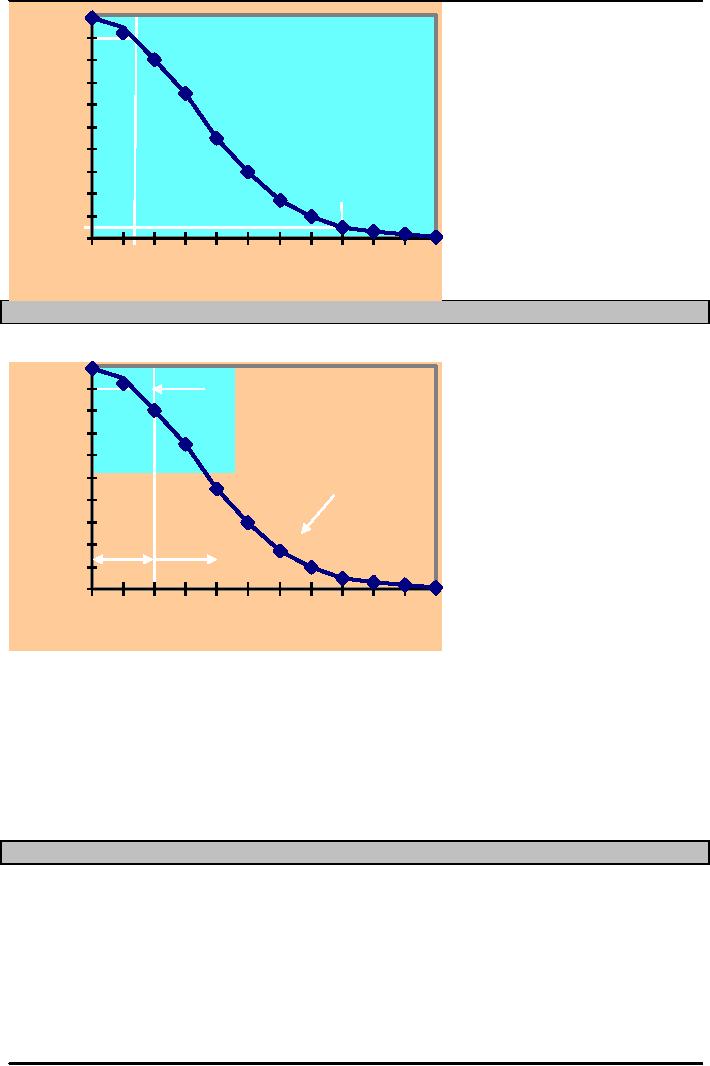

CONSUMER'S

AND PRODUCER'S RISK

133

Production

and Operations Management

MGT613

VU

1

α=

Proba

0.9

bility

of

0.8

accepti

ng

lot

0.7

0.6

0.5

LTP

0.4

0.3

Indifferen

"Bad

"Good

0.2

0.1

β=

0

.05

.10

.15

.20

.25

0

Lot

quality (fraction

defective)

AQ

1

.913

0.

Pr

0.

.736

ob

0.

ab

0.

.544

ilit

0.

y

0.

.375

of

0.

.244

ac

0.

.149

ce

.086

0.

pt

0

an

.1

.3

.4

.5

.20

0

Fraction

defective in lot

Average

Quality is the Average outgoing

quality (AOQ): Average of inspected

lots (100%) and un

inspected

lots

134

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMERíS AND PRODUCERíS RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model