|

Total

Quality Management

MGT510

VU

Lesson

# 44

UNDERSTANDING

EMPOWERMENT FOR TQ AND

CUSTOMER-SUPPLIER

RELATIONSHIP

Introduction

to Empowerment

Empowerment

means giving someone

power-granting the authority to do

whatever is necessary to

satisfy

customers, and trusting employees to make the

right choices without

waiting for

management

approval.

By empowering employees, organizations

drive decision making down

to its lowest possible

level.

Empowerment allows organizations to

flatten their organizational structure

because fewer

managers

are needed to "direct and

control" employees. Many companies have

found that giving

people

throughout

the organization the power to make a

difference contributes greatly to

providing quality

products

and services to their customers.

The need to empower the entire

workforce in order for

quality

to

succeed has long been

recognized, even if it is only recently

coming into practice. Five of

Deming's

14

Points relate directly to the nation of

empowerment.

Point

6:

Institute

training

Point

7:

Teach

and institute leadership

Point

8:

Drive

out fear. Create trust.

Create a climate for

innovation

Point

10:

Eliminate

exhortations for the

workforce.

Point

13:

Encourage

education and self-improvement for

everyone

Juran

wrote that "ideally, quality

control should be delegated to the

workforce to the maximum

extent

possible."

Empowerment resembles Juran's

concept of "self-control." For employees

to practice self-

control,

they must know their

unit's goals and their actual performance and have a

means for changing

performance

if the goals are not being

met. Although it is a difficult

struggle, organizations

are

increasingly

meeting these conditions.

Empowerment is a natural extension of

employee involvement

concepts

such as worker participation in

decision making. In some

companies empowerment is used as

the

umbrella term for increasing

employee involvement in decision

making. Empowerment is more

than

another

term for involvement,

however. It represents a high

degree of involvement in which

employees

make

decisions themselves and are responsible

for their outcomes. This is

a more radical change

than

having

employees merely participate in managers' decisions,

even when they are given

some influence.

For

empowerment to occur, managers must

undertake tow major

initiatives:

·

Identify

and change organizational conditions

that make people powerless,

and

·

Increase

people's confidence that

their efforts to accomplish something

important will be

successful.

The

need to do both of these

implies that organizational

system often creates

powerless employees and

that

these systems must be

changed first. Examples of systems in

need of change are those

that specify

who

can (and cannot) make

certain types of decisions and systems of

standard operating

procedures

(and

who can override

them).

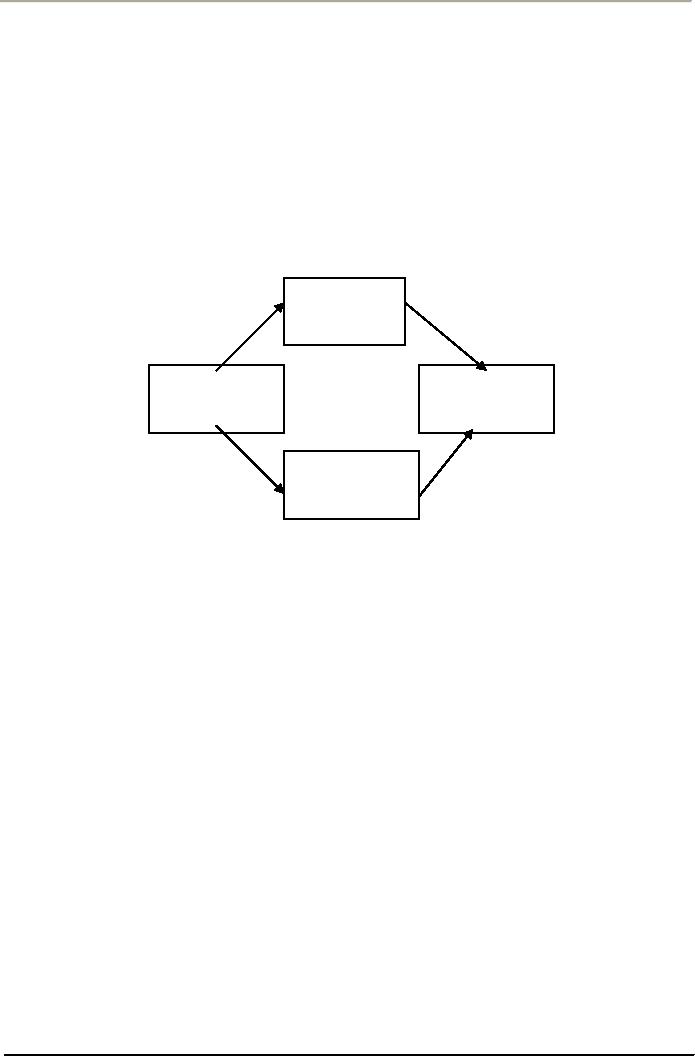

Continuum

of Employee Involvement Practices

Participation

Empowerment

Low

High

Involvement

Small

Large

Change

from Traditional Organizational

Style

175

Total

Quality Management

MGT510

VU

Even

when systems are changed to

permit empowerment, individuals who have

lived under those

systems

are not readily able to

operate in an empowered manner. The other

need for empowering

people

is

to deal with the psychological

aftereffects of powerlessness by

convincing people that they

are in fact

able

to "make a difference."

Empowerment

is an application of the teamwork

principle of total quality,

embodying "vertical"

teamwork

between managerial and non managerial

personnel. If employees are given

important

responsibilities

and the authority that goes

along with them it is more

realistic to describe

their

relationship

with management as teamwork

than it would be in hierarchical

system. After all, people

can

hardly

be seen as team members if

they only execute decisions

made by others.

How

Empowerment Leads To

Quality

Continuous

Improvement

Quality

Products

and

Customer

Empowerment

Service

Job

Satisfaction

Everyone

in organizations is an asset, albeit an

asset whose value is not

automatically realized. If

money

is

put into a closet instead of a

bank, it will not gain

interest. Employees who are put

into jobs that

are

like

being in a closet (in the

dark, isolated) similarly

will not provide value to

the organization. Giving

employees

responsibility for their own

work has led not

only to improvements in motivation,

customer

service,

and morale, but also to

improvements in quality, productivity,

and the speed of decision

making.

Principles

of Empowerment

Although

many organizations have undertaken the

journey toward empowerment, many have

become

lost

along the way. Semi empowerment just

doesn't work. Senior

managers need to ask three

critical

questions:

1.

How

can I make fewer decisions,

thereby letting others

become more involved in

managing

the

business?

2.

How

can teach others how to

make solid decisions once

they're given the

chance?

3.

How

can I recruit others to be more

aware of changes that need

to be made in order to keep

our

company competitive and then help

them feel they can make

these changes without

begging

for permission each and every

time?

This

does not mean that there

should be no limits. On the contrary,

managers must be clear on

exactly

what

responsibility and authority rests

with employees. Questions such as

"What procedures can

we

change?"

and "how much money

can we commit?" must be

answered ahead of time.

Finally, managers

must

be willing to wait for

results, as miracles do not happen

overnight.

176

Total

Quality Management

MGT510

VU

Establishment

Mutual Trust

As

Juran has put it, "The

managers must trust the

workforce enough to be willing to make

the

delegation,

and the workforce must have

enough confidence in the managers to be

willing to accept the

responsibility."

Trust is not created just by

saying you trust someone; it

must be backed up by actions.

Provide

Employees wit Business

Information

For

empowerment to succeed, it must focus on

making the organization more

competitive.

Empowerment

can contribute to organizational

performance only if employees have access to

the

necessary

information about the business and

its performance, such as their personnel

files and

resources

such as the quality improvement

budget. Information about the

employees' department or

other

subunit is particularly necessary, as

this is the level of performance that

they can affect.

Sharing

business

information with employees relates

directly to quality, customer service,

and competitiveness.

In

the absence of appropriate information,

empowered employees may squander their

power on

problems

that are not very

important. As Peter Senge

has put it, "empowering the

individual where there

is

a relatively low level of

alignment [between organizational

and employee goals] worsens

the chaos

and

makes managing . . . even more

difficult."Te criticism of misplaced goals

was often leveled at

earlier

employee-involvement efforts, such as

quality circles. Although managers

formerly blamed

employees

for having the wrong

priorities, sophisticated managers today

recognize that they

are

responsible

for providing employees with the

information necessary to develop

educated priorities.

Ensure

That Employees Are

Capable

"You

can't empower incompetence," says

one manager. If employees are going to

take on important

organizational

responsibilities, they must be prepared t

do so. To operate in an empowered, TQ

environment,

employees must possess not

only technical skills

(including statistics) but

also

interpersonal

and problem-solving skills.

Unfortunately, many people

entering the workforce today

lack

even

the most basic skills in

reading and math, let alone

these relatively advanced

skills.

Employee

capability can be ensured

through selection and training processes.

Unless the human

resource

processes are adapted to

provide capable employees, empowerment cannot

succeed, and

management's

worst nightmares will be realized.

Unfortunately, many employees are

not trained in

these

areas, which helps explain the

mixed results many

organizations have had with

empowerment.

Empowerment

also requires that employees understand

their appropriate limits of

discretion.

Don't

Ignore Middle

Management

A

well-known principle of organization

theory popularized by Deming is

that organizations are

systems.

When

changing one part of an organization, it

is necessary to consider the effects of the change on

other

parts

of the system. Thus, managers must

consider how empowering lower-level

employees will affect

middle

managers. If the needs and expectations

of middle manager are

ignored, empowerment will be

confusing

at best and disastrous at worst.

Among the roles for middle

managers in organizations

with

empowered

workforces are

·

Maintaining

focus on the organization's values,

·

Managing

solutions to system-level problems (those

that involve many functions

and

departments),

and

·

Acting

as teachers and coaches.

It's

tempting to think of middle

managers faced with empowerment efforts

as dinosaurs, rapidly

becoming

extinct because the world

has changed too quickly

for them. However, remember

that most

middle

managers are a product of

their organizations and have attained

their level of success in

an

177

Total

Quality Management

MGT510

VU

environment

that rewarded different things

than are needed from

managers now. Given a new

set of

instructions

from top management, backed up by

new performance appraisal criteria. Many

(but far

from

al) managers will be able to

make the necessary transition.

Change

the Reward System

Rarely

can substantial organizational change be

created without changing the

reward system. When

organizations

ask employees to assume new challenges

and responsibilities, the question

"What's init

for

me?" ultimately gets asked.

The reward system includes

all of the rewards that employees

receive, as

well

as the criteria for distributing

these rewards. An organization is to

its reward system like a

boat is to

its

anchor: unless the reward system is

changed, the organization may

drift a little bit in one

direction or

another,

but it won't get very

far.

It

is hard to specify exactly what

kind of reward systems will

be needed to complement empowerment.

Some

of the practices common to organizations

utilizing employee involvement

include pay-for-skills,

in

which employees' pay

increases as they learn new

job-relevant skills, and

profit sharing, in which

employees

receive bonuses related to the

profits of their

organization.

Quality

in Customer-Supplier Relationships

Businesses

have recognized that supply chain

management is crucial for

effective operations and

meeting

customer needs. A supply

chain includes the materials and

other inputs purchased

from

suppliers,

their use in the production of

goods and services, and distribution and

service to customers.

Quality

should start with the customer, and

extend back through the supply

chain to the root sources

of

procurement.

Customer-Supplier

Relationship and Total

Quality

From

the TQ perspective, every company is part of a

long chain (actually many

long chains) of

customers

and suppliers. Each company is a customer

to its suppliers and a supplier to

its customers, so

it

does not make sense to

think of a company as only one or the

other. One implication of

this concept is

that

your customer's customers are, in a

sense, your customers as

well. Sometimes a company

must

focus

on both their immediate

customers and those next in the

chain. Procter & Gamble, for

example,

works

hard to satisfy the needs of both the

people who use their

products and the retail

establishments

that

sell them, labeling the former

"consumers" and the latter

"customers."

Companies

should try to establish the same

kinds of productive relationships

with their suppliers

that

they

have with their customers. By

developing partnerships, customers and suppliers

can build

relationships

that will help them satisfy

their shared customers

further along the

customer-supplier

chain.

The idea of creating

mutually beneficial relationships

with both customers and suppliers is

a

major

departure from the traditional approach to

customer and supplier relationships

(CSRs).

The

Customer-Supplier Chain

Customer/

Customer/

Supplier

Supplier

Customer/

(Coal

Mine)

Customer/

Supplier

(Steel

mill)

Supplier

(Auto

plant)

(Car

rental agency)

178

Table of Contents:

- OVERVIEW OF QUALITY MANAGEMENT:PROFESSIONAL MANAGERIAL ERA (1950)

- TOTAL QUALITY MANAGEMENT AND TOTAL ORGANIZATION EXCELLENCE:Measurement

- INTEGRATING PEOPLE AND PERFORMANCE THROUGH QUALITY MANAGEMENT

- FUNDAMENTALS OF TOTAL QUALITY AND RATERS VIEW:The Concept of Quality

- TOTAL QUALITY MANAGEMENT AND GLOBAL COMPETITIVE ADVANTAGE:Customer Focus

- TOTAL QUALITY MANAGEMENT AND PLANNING FOR QUALITY AT OFFICE

- LEADERS IN QUALITY REVOLUTION AND DEFINING FOR QUALITY:User-Based

- TAGUCHI LOSS FUNCTION AND QUALITY MANAGEMENT

- WTO, SHIFTING FOCUS OF CORPORATE CULTURE AND ORGANIZATIONAL MODEL OF MANAGEMENT

- HISTORY OF QUALITY MANAGEMENT PARADIGMS

- DEFINING QUALITY, QUALITY MANAGEMENT AND LINKS WITH PROFITABILITY

- LEARNING ABOUT QUALITY AND APPROACHES FROM QUALITY PHILOSOPHIES

- TOTAL QUALITY MANAGEMENT THEORIES EDWARD DEMING’S SYSTEM OF PROFOUND KNOWLEDGE

- DEMING’S PHILOSOPHY AND 14 POINTS FOR MANAGEMENT:The cost of quality

- DEMING CYCLE AND QUALITY TRILOGY:Juran’s Three Basic Steps to Progress

- JURAN AND CROSBY ON QUALITY AND QUALITY IS FREE:Quality Planning

- CROSBY’S CONCEPT OF COST OF QUALITY:Cost of Quality Attitude

- COSTS OF QUALITY AND RETURN ON QUALITY:Total Quality Costs

- OVERVIEW OF TOTAL QUALITY APPROACHES:The Future of Quality Management

- BUSINESS EXCELLENCE MODELS:Excellence in all functions

- DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership

- DEVELOPING ISO QMS FOR CERTIFICATION:Process approach

- ISO 9001(2000) QMS MANAGEMENT RESPONSIBILITY:Issues to be Considered

- ISO 9001(2000) QMS (CLAUSE # 6) RESOURCES MANAGEMENT:Training and Awareness

- ISO 9001(2000) (CLAUSE # 7) PRODUCT REALIZATION AND CUSTOMER RELATED PROCESSES

- ISO 9001(2000) QMS (CLAUSE # 7) CONTROL OF PRODUCTION AND SERVICES

- ISO 9001(2000) QMS (CLAUSE # 8) MEASUREMENT, ANALYSIS, AND IMPROVEMENT

- QUALITY IN SOFTWARE SECTOR AND MATURITY LEVELS:Structure of CMM

- INSTALLING AN ISO -9001 QM SYSTEM:Implementation, Audit and Registration

- CREATING BUSINESS EXCELLENCE:Elements of a Total Quality Culture

- CREATING QUALITY AT STRATEGIC, TACTICAL AND OPERATIONAL LEVEL

- BIG Q AND SMALL q LEADERSHIP FOR QUALITY:The roles of a Quality Leader

- STRATEGIC PLANNING FOR QUALITY AND ADVANCED QUALITY MANAGEMENT TOOLS

- HOSHIN KANRI AND STRATEGIC POLICY DEPLOYMENT:Senior Management

- QUALITY FUNCTION DEPLOYMENT (QFD) AND OTHER TOOLS FOR IMPLEMENTATION

- BASIC SQC IMPROVEMENT TOOLS:TOTAL QUALITY TOOLS DEFINED

- HOW QUALITY IS IMPLEMENTED? A DIALOGUE WITH A QUALITY MANAGER!

- CAUSE AND EFFECT DIAGRAM AND OTHER TOOLS OF QUALITY:Control Charts

- STATISTICAL PROCESS CONTROL (SPC) FOR CONTINUAL QUALITY IMPROVEMENT

- STATISTICAL PROCESS CONTROL….CONTD:Control Charts

- BUILDING QUALITY THROUGH SPC:Types of Data, Defining Process Capability

- AN INTERVIEW SESSION WITH OFFICERS OF A CMMI LEVEL 5 QUALITY IT PAKISTANI COMPANY

- TEAMWORK CULTURE FOR TQM:Steering Committees, Natural Work Teams

- UNDERSTANDING EMPOWERMENT FOR TQ AND CUSTOMER-SUPPLIER RELATIONSHIP

- CSR, INNOVATION, KNOWLEDGE MANAGEMENT AND INTRODUCING LEARNING ORGANIZATION