|

Transportation Problems:MOVING TOWARDS OPTIMALITY |

| << Transportation Problems:FINDING AN INITIAL BASIC FEASIBLE SOLUTION |

| Transportation Problems:DEGENERACY, Destination >> |

Operations

Research (MTH601)

176

MOVING

TOWARDS OPTIMALITY

The

rationale behind

optimality

Given

an initial non-degenerate basic

feasible solution, a question

may arise as to how we can

find a

successively

better basic feasible

solution. This means that we

have to select an entering

variable, a leaving

basic

variable and identify the

corresponding solution. In the

transportation model, selecting an

entering variable

means

selecting a new cell in which to

make a non-zero allocation in the

transportation matrix. The principle

of

selecting

the variable which improves

the value of the objective

function (minimizes the total

transportation

cost),

at the fastest rate is still

valid. So we select an unoccupied

cell and make a unit

allotment, so that the

cost

of

transportation will decrease by

the greatest amount.

To

illustrate, suppose that in the

example 4.1 we choose arbitrarily

the cell (B, P) which is

unoccupied

and

make + 1 allotment in this cell. This new allocation automatically

violates the supply

situation and demand

requirements

of the origin B and

destination P. So changes are

required in other cells to

restore feasibility. This

necessitates

a reallocation in the cells to

restore feasibility. This necessitates a

reallocation in the cells

(B, P),

(A,

P), (A, Q) and (B,

Q). The row total and column

total will be unaltered. This idea is

illustrated in tables 17 to

19.

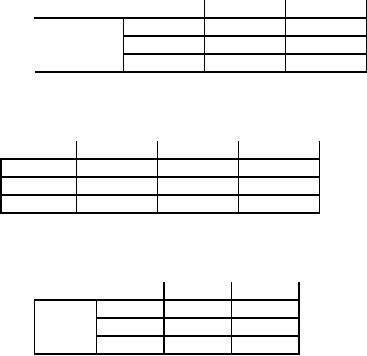

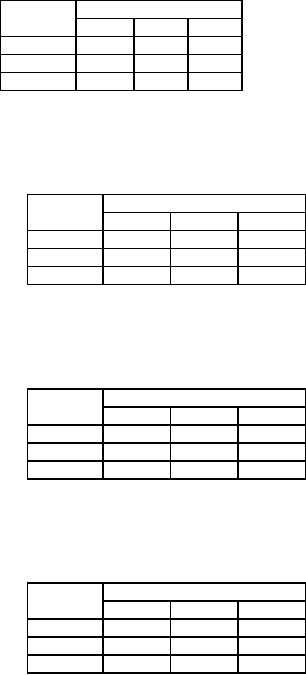

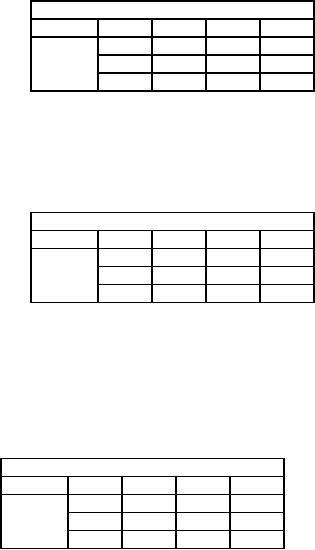

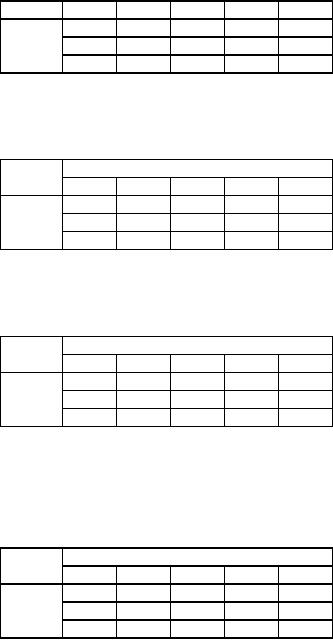

Table

17

P

Q

R

A

5

7

8

B

4

4

6

C

6

7

7

Unit

cost of transportation

Table

18

P

Q

R

A

65

5

70

B

30

30

C

7

43

50

65

42

43

Table

19

P

Q

R

A

65-1

5+1

70

B

1

30-1

30

C

7

43

50

65

42

43

Changed

allotment

The

unit costs in the cells

(B, P), (A, P),

(A, Q) and (B, Q) are 4, 5,

7, 4 respectively (refer table

17).

The

total change in the total cost

will be 4 - 5 + 7 - 4 = + 2. We see that

this arbitrary unit allotment to cell

(B,

P)

increases the transportation

cost by rupees 2. Hence an allocation to

the cell (B, P) is not

recommended.

This

procedure is repeated by choosing

some other unoccupied cell

for allocation. This

requires

corresponding

changes in the allocation in the

occupied cells to restore

feasibility and calculation of

the

176

Operations

Research (MTH601)

177

marginal

cost. If, by this procedure,

we get a +ve

value,

it indicates that the total

cost is not decreasing

but

increasing.

Consider

the objective function to

minimize,

mn

Z=∑∑

c

x

ij

ij

i

=1

j

=1

and

the restrictions as

n

0

=

ai - ∑ xij for

i

=

1,2, ...

,

m

j

=1

m

0

=

b

-

∑ xij for

j = 1,2, ...

,

n

j

i

=1

Multiply

each of these equations by a

number and add this

multiple to the objective function.

This resultant can

be

used to eliminate the basic

variable. Let us represent the

multiples by ui (i =

1, 2, ..., m)

and vj =

(j

=

1, 2, ...,

n)

respectively for rows and

columns. These multipliers

are called the simplex

multipliers.

Therefore,

⎡

⎤

m

m

n

n

+

∑ ui ⎢

ai - ∑

xij ⎥

Z

=

∑ ∑ cij

x

i

=1

⎢

⎥

ij

i

=1

j

=1

⎣

j

=1

⎦

⎡

⎤

n

m

+

∑ v

j ⎢b j - ∑

xij ⎥

⎢

i

=1

⎥

⎣

⎦

j

=1

m

m

n

n

(

)

=

∑ ∑ cij -ui -v j x

+ ∑

ui ai

+

∑ v

j b j

ij

i

=1

j

=1

i

=1

i

=1

Thus

in order to have a zero coefficient

(for a basic variable) it is

necessary that

crs =

ur +

vs

for

each basic variable

xrs (i.e.)

for each occupied cell

(r,

s).

There are (m

+ n - 1)

occupied cells and

therefore

(m + n

-

1) equations. Since we have

(m

+ n) unknown

(ui's

and

vj's)

one of these variables can

be assigned a

177

Operations

Research (MTH601)

178

value

arbitrarily and rest of them

can then be solved algebraically. This

leads to the solution of a set of (m

+

n

- 1) equations simultaneously.

Having

determined the values of

ui and

vj,

the entering basic variable

(if any) can be identified

readily

by

calculating cij -

(ui +

vj) for

each of the unoccupied

cells. If cij -

(ui +

vj) > 0 in

every case, then the

solution

must

be optimal since no non-basic

variable can decrease

Z.

On the other hand if

cij -

(ui +

vj)

yields a negative

result,

the cell with the

largest negative (smallest)

value of cij -

(ui +

vj) is

selected to be the cell for

new

allocation

since it means that this

non-basic variable decreases Z at

the fastest rate. This is

the basis for

conducting

the optimality test, which

is explained in the next

section.

Optimality

test:

For

conducting the optimality

test to any feasible solution of a

(mxn)

transportation problem,

the

following

two conditions must be

satisfied.

1.

It

consists of exactly

(m + n

-

1) individual cells being

allocated.

2.

These

allocations are in independent

positions.

The

first condition is normally satisfied in

many problems. If the first

condition is not satisfied then it

results in

a

state known as degeneracy, in

the transportation mode. The

discussion of degeneracy and

its resolution is

explained

in a later section.

A

set of allocations comprising a feasible

solution is said to be in 'independent

positions' if it is

impossible

to increase or decrease any

individual allocation without either

changing the positions of

allocations

or

violating the row or column

restrictions. In other words, a simple criterion

for independence is that, it

is

impossible

to travel from any allocation

back to itself, by a series of

alternating horizontal and vertical

jumps

from

one occupied cell to

another, without a direct

reversal of route.

For

example, if the occupied cells

form a closed loop as in

table 20 they are not in

independent

positions

Table

20

*

*

*

*

Applying

the procedure outlined above

to the initial basic

feasible solution, (found by

any method) we have

the

following

steps in conducting an optimality

test.

STEP

1:Write

the matrix of allotment found by

NWC rule or by Vogel's Approximation

Method. Check for

conditions

for optimality (i.e.) there

must be (m + n - 1) alloted cells

and all of them must be in

independent

positions.

If these two conditions are

satisfied, proceed to step

2.

STEP

2:Write

the matrix of the cost of

the alloted cells.

STEP

3:Determine

a set of (m

+ n)

numbers,

ui,

i

=

1, 2, ..., m

vj,

j

=

1, 2, ..., n

178

Operations

Research (MTH601)

179

called

simplex multipliers such

that for each occupied

cell (r, s).

crs =

ur + vs

where

crs is

the individual cost of an allocation

from origin r

to

destinations s.

This

can be done by arbitrarily

assigning, any one of the

ui's

or

vj's,

any value (say 0) and

satisfying the above

equation

for all the occupied

cells.

STEP

4:Write

the matrix of cost elements

for all unoccupied

cells.

STEP

5:Find

(ur +

vs) for

each unoccupied cell and

form the matrix of

(ui +

vj) for

each of the unoccupied

cell.

STEP

6:Calculate

cij -

(ui +

vj) for

each of the unoccupied

cells. This is the matrix of

cell evaluation or square

evaluation.

If the value of cell

evaluation is positive, it indicates that

the solution already found is optimal. If

it

is

negative there is a scope

for relocation of items so

that the total cost of

transportation can be made

minimum.

If

there are many negative

entries in the matrix of

cell evaluation, select the

cell yielding the most

negative entry

as

the entering variable. This

requires reallotment of the allocation

matrix. By including this cell

for occupation,

the

allocations of the other

occupied cells require a

revision to fulfill the row

and column restrictions. If

the

value

of cell evaluation is zero,

then this indicates that

there exists another solution to

the transportation

problem

without

reducing the total

cost.

Consider

the example whose cost

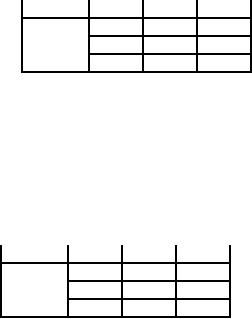

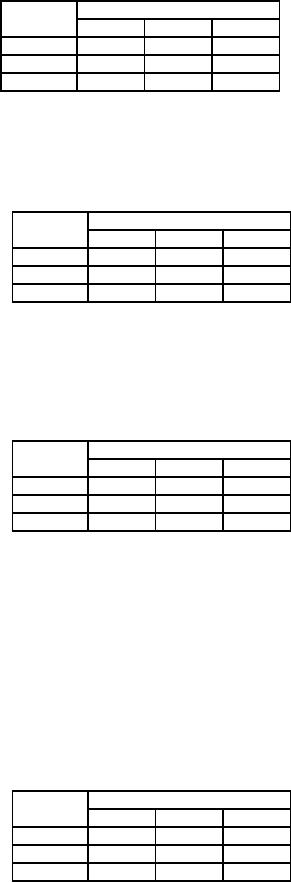

matrix is as in table 21

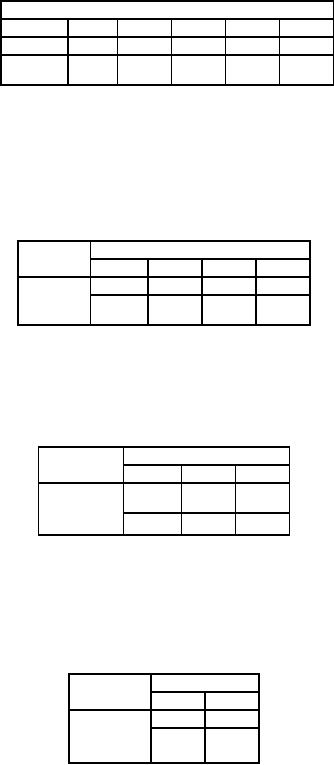

Table

21

Origin

Destination

Supply

P

Q

R

A

5

7

8

70

B

4

4

6

30

Cost

Matrix

C

6

7

7

50

Demand

65

42

43

We

have the allocation as per

NWC rule as in table

22

Table

22

Origin

Destination

Supply

P

Q

R

A

65

5

70

B

30

30

Allotment

Matrix

C

7

43

50

Next

we write the matrix of the

cost of alloted cells and

using explained below and

shown in table 23

Table

23

179

Operations

Research (MTH601)

180

ui

Origin

Destination

P

Q

R

A

5

7

-

0

u1

B

-

4

-

-3

Finding

ui,

vj using

the

u2

C

0

cost

of the occupied cells

-

7

7

u3

vj

v1

v2

v3

5

7

7

To

determine ui's

and

vj's

we arbitrarily

assign one of the

multipliers say u3 the

value 0.

Then

it follows that v2 = 7 because we have the

equation

u3 +

v2 = 7

Since

u3 +

v3 = 7

we

have

v3 = 7

Similarly

using the cost elements of

the occupied cells and

with the equation crs =

ur + vs, we

can find

the

values of ui's

and

vj's.

The

unoccupied (un-allotted) cells

are indicated by placing

dots in the cells.

Next

we write the matrix of the

cost elements cij of

the unoccupied cells as in

table 24.

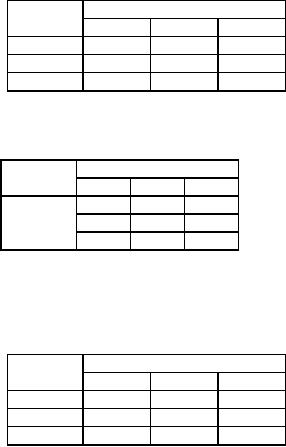

Table

24

Origin

Destination

P

Q

R

A

8

B

4

6

cost

of

C

6

unoccupied

cells

Next

we write the matrix of

ui + vj

for

unoccupied cells as in

Table

25

Origin

Destination

P

Q

R

A

7

B

2

4

(ui +

vj)

for

C

5

unoccupied

cells

Table

26

Origin

Destination

P

Q

R

A

1

B

2

2

Cell

Evaluation

180

Operations

Research (MTH601)

181

C

1

Next

we write the matrix of

ui +

vj for

unoccupied cells as in table

25. Next we find cij -

(ui +

vj) for

all

the

unoccupied cells. This

matrix is obtained by subtracting

the elements in the

(ui +

vj)

matrix from the

corresponding

elements of cij in

the matrix of the cost of

unoccupied cells. This is the

matrix of cell evaluation

or

square evaluation as shown in

table 26.

We

see that all the

elements of the matrix of

cell evaluation are positive

(>

0).

This indicates that

our

initial

basic solution is optimal and

the cost of transportation is

Rs. 830. If the elements of

matrix of cell

evaluation

are negative, it indicates

that further reduction in

cost is possible.

Example

Mam

enterprise has three

factories located at A, B and C

and supplies to three

warehouses located at D,

E

and F. Monthly factory capacities

are 10, 80 and 15 units

respectively. Monthly warehouse

requirements are

45,

20 and 40 units respectively.

Unit transportation costs in

rupees are given

below.

Warehouse

Factory

D

E

F

A

5

1

7

B

6

4

6

C

3

2

5

Starting

with NWC rule, find

the optimal allotment.

Solution:

Using

NWC rule we obtain the

initial basic feasible solution as in

table 27.

Table

27

Warehouse

Factory

D

E

F

Supply

A

10

10

0

B

35

20

25

80

45

25

0

C

15

15

0

45

20

40

35

15

0

0

0

There

are five allotments. As per

the optimality test

conditions there must be (3 + 3 - 1)

cells occupied

and

we see that this condition is

satisfied. Secondly all the

cells should be in independent

positions.

To

test the cells whether

they are independent or not,

we take an occupied cell and

alter the allotment in

that

cell by one unit. This requires

the change in other occupied

cells without violating the

constraints. Or if we

start

from one occupied cell

and we do come back to the

starting cell, then the

cells are in dependent

positions.

In

the above problem all

the cells are

independent.

Having

satisfied the two conditions

we proceed to the optimality

test as described above and

are carried

in

tables 28 to 33

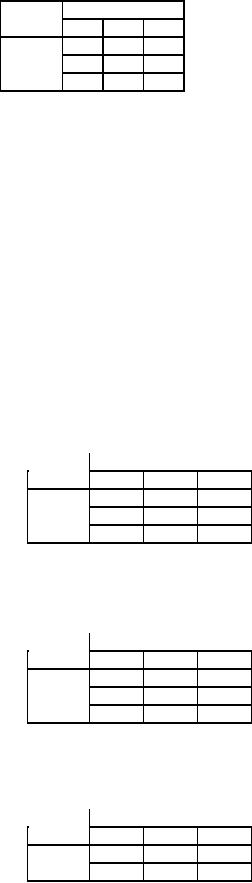

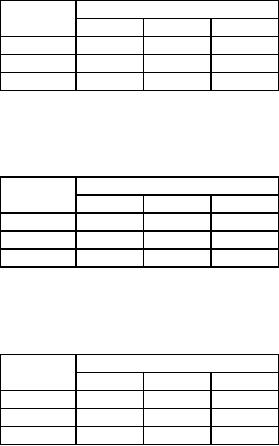

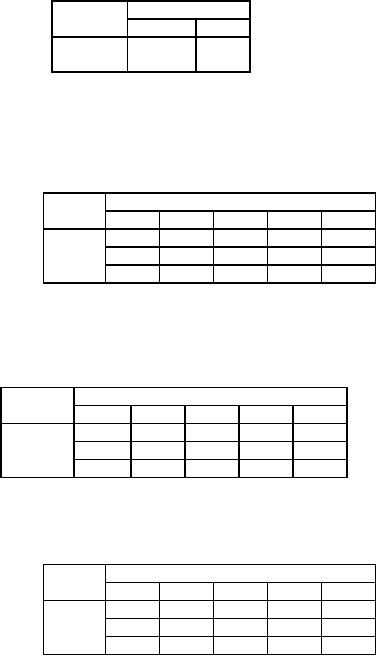

Table

28

181

Operations

Research (MTH601)

182

Factory

Warehouse

D

E

F

A

5

1

7

B

6

4

6

C

3

2

5

Cost

Matrix

Table

29

Factory

Warehouse

D

E

F

A

10

B

35

20

25

C

15

Allotment

Matrix

182

Operations

Research (MTH601)

183

Table

30

Factory

Warehouse

ui

D

E

F

A

5

-

-

0

u1

B

6

4

6

1

u2

C

-

-

5

0

u3

vj

v1

v2

v3

5

3

5

Evaluation

ui and

vj

Table

31

Factory

Warehouse

D

E

F

A

1

7

B

C

3

2

Cost

of un-allotted cells

Table

32

Factory

Warehouse

D

E

F

A

3

5

B

C

5

3

(u1 +

vj) for

un-allotted cells

Table

33

Factory

Warehouse

D

E

F

A

-2

2

B

C

-2

-1

Cell

Evaluation

In

the matrix of cell

evaluation, there are three

cells (A, E), (C, D), and

(C, E) having negative

entries

indicating

the scope of minimizing the

cost by bringing any of these

cells for occupation. But

the most negative

element

is found in two cells (A, E)

and (C, D). Since

there is a tie, the same is

broken arbitrarily. We select

the

cell

(C, D) for reallotment (as

marked in table 34). With

the initial feasible

solution,

Table

34

183

Operations

Research (MTH601)

184

Warehouse

Factory

D

E

F

A

10

B

35

20

25

C

15

we

have to allocate as much as

possible in the empty cell

(with the mark) with the

most negative evaluation

to

arrive

at the minimum cost as

quickly as possible. The

reallocation is performed by identifying

the loop joining

the

empty cell to the occupied

cells by horizontal and vertical jumps as

indicated in table

35.

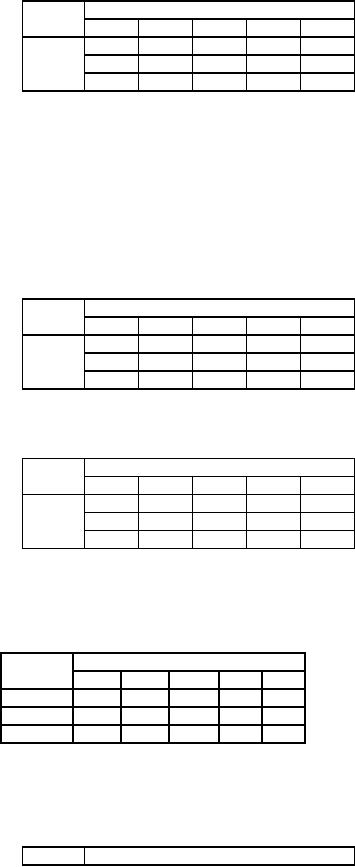

Table

35

Factory

Warehouse

D

E

F

A

10

B

35

20

25

C

15

It

can be seen that we can

allocate 15 units to cell

(C, D) and still satisfy

the row and column total

and

thus

no allocation becomes negative. The

effect of allotting 15 units to

empty cell leads to the

matrix of

reallotment

as shown in table 36.

Table

36

Factory

Warehouse

D

E

F

A

10

B

20

20

40

C

15

Reallotment

among cells of loop

We

conduct optimality test to

see whether this solution is optimal.

The computations are carried

in

tables

37 to 42. From the table 42

we see that the unoccupied

cell (A, E) has a negative

evaluation and hence

there

exists another feasible solution as

shown in table 4

We

have to conduct the

optimality test to find

whether the third feasible solution is

optimal. By

carrying

out the iterations (not

shown), we observe that the

third feasible solution (Table 43) is

optimal and the

corresponding

cost is

10

×

1

+

30

×

6

+

10

×

4

+

40

×

6

+

15

×

3

=

Rs.

515.

Table

37

Factory

Warehouse

D

E

F

A

5

1

7

B

6

4

6

C

3

2

5

184

Operations

Research (MTH601)

185

Cost

Matrix

Table

38

Factory

Warehouse

D

E

F

A

10

B

20

20

40

C

15

Allotment

Matrix

Table

39

Factory

Warehouse

ui

D

E

F

A

5

-1

B

6

4

6

0

C

3

-3

6

4

6

vj

Cost

of alloted cells & Evaluation of

ui and

vj

Table

40

Factory

Warehouse

D

E

F

A

1

7

B

C

2

5

Cost

of unalloted cells

185

Operations

Research (MTH601)

186

Table

41

Factory

Warehouse

D

E

F

A

3

5

B

C

1

3

(ui +

vj)

for unalloted cells

Table

42

Factory

Warehouse

D

E

F

A

-2

2

B

C

1

2

Cell

Evaluation

Table

43

Factory

Warehouse

D

E

F

A

10

B

30

10

40

C

15

Reallotment

Vogel's

Approximation Method for

maximization problem

The

VAM method can be used in a

maximization problem making a slight

modification. The

required

modification

is to multiply all the

elements in the (profit)

matrix by -1, with the

concept that minimizing

the

negative

of a function maximizes the original

function.

Consider

the example given

below.

186

Operations

Research (MTH601)

187

Example:

Solve

the following transportation

problem to maximize profit

and give criteria for

optimality.

Profits

(Rs) / Unit

Destination

Origin

1

2

3

4

Supply

A

40

25

22

33

100

B

44

35

30

30

30

C

38

38

28

30

70

Demand

40

20

60

30

We

first convert the elements

of profit matrix by multiplying by -1

and then we adopt

the

Solution:

method

of minimization. This is done in

table 44

Table

44

Destination

Origin

1

2

3

4

Supply

A

-40

-25

-22

-33

100

B

-44

-35

-30

-30

30

C

-38

-38

-28

-30

70

Demand

40

20

60

30

In

the above problem total

supply is not equal to total

demand. (supply demand) and

hence it is an

unbalanced

transportation model. To balance, we

introduce a dummy column 5. to find

the initial feasible

solution

by VAM. We put the elements in

the dummy column 90 as in table

45

Table

45

Destination

Origin

1

2

3

4

Supply

(Penalty

A

-40

-25

-22

-33

100

(7)

B

-44

-35

-30

-30

30

(9)

C

-38

-38

-28

-30

70

(0)

Demand

40

20

60

30

Penalty

(4)

(3)

(2)

(3)

Allot

in the row B having maximum

penalty and in the cell

(B, I) with least

cost.

The

origin B is deleted for

further analysis as it is exhausted. We

have the reduced matrix

given in table

46.

187

Operations

Research (MTH601)

188

Table

46

Destination

Origin

1

2

3

4

5

Supply

Penalty

A

-40

-25

100

(7)

20

-28

-30

0

70

(0)

C

-38

-38

Demand

10

20

60

30

50

Penalty

(2)

(13)

(6)

(3)

(0)

Allot

in the column (2), which has

a maximum penalty (13) and

in the cell (C, 2) with

least cost. Column 2 is

deleted

as the supply is satisfied

and we have the reduced

matrix as in table 46

Table

47

Origin

Destination

Supply

Penalty

1

3

4

5

A

-40

-22

-33

0

C

10

-28

-30

0

100

(7)

-38

Demand

10

60

30

0

50

(8)

Penalty

(2)

(6)

(3)

(0)

Allot

(C, 1) with 10 units and

delete column 1. Then we have

table 48

Table

48

Origin

Destination

Supply

Penalty

3

4

5

30

0

100

(11)

A

-22

-33

-28

-30

0

40

(2)

C

Demand

60

30

50

Penalty

(6)

(3)

(0)

Allot

30 to cell (A, 4) and delete

column 4. Then we have table

49

Table

49

Origin

Destination

Supply

Penalty

3

5

A

-22

0

70

(22)

40

-28

C

0

40

(28)

Demand

60

50

Penalty

(6)

(0)

Deleting

row C we have the table 50

as we allot 40 to cell (C,

3).

Table

50

188

Operations

Research (MTH601)

189

Destination

Supply

Origin

3

5

50

20

0

-22

70

A

Demand

20

50

Thus

we have the initial feasible

solution given in table 51

Table

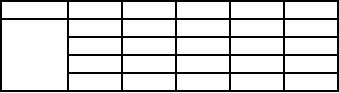

51

Origin

Destination

1

2

3

4

5

A

20

30

50

B

C

10

20

40

Allotment

Matrix

The

optimality test is conducted

table 52 to 55

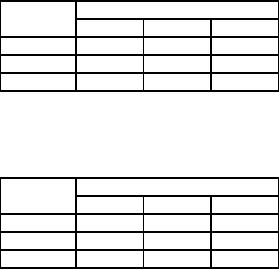

Table

52

Origin

Destination

1

2

3

4

5

ui

A

-

-

-22

-30

0

6

B

-44

-

-

-

-

-6

C

-38

-38

-28

-

-

0

-38

-38

-28

-36

-6

vj

Evaluation

of ui's

and

vj's

Table

53

Origin

Destination

1

2

3

4

5

A

-40

-25

B

-35

-30

-30

0

C

-30

0

Cost

of un-allotted cells

189

Operations

Research (MTH601)

190

Table

54

Origin

Destination

1

2

3

4

5

A

-32

-32

B

-44

-34

-42

-12

C

-36

-6

(ui +

vj) for

unalloted cells

From

table 55 see that the

cell (A, 1) has a negative

value indicating that there is

scope for optimality.

This

is a potential box to be alloted.

Therefore we go back to the allotment

matrix in table 51.

Allotting to cell

(A,

1) we have to remove from

cell (A, 3), add to

cell (C, 3) and remove

from cell (C, 1) so that

the loop is

complete

indicating that reallotment is possible.

Now we have to decide the

amount to be alloted and this

is

decided

with the idea that in

the process of reallotment no

cell can have negative

allotment. Hence we have

the

new

allotment as per the following

table 56

Table

55

Origin

Destination

1

2

3

4

5

A

-8

-7

B

9

4

12

12

C

6

6

Cell

Evaluation

Table

56

Origin

Destination

1

2

3

4

5

A

10

10

30

50

B

30

C

20

50

Reallotment

Table

57

Origin

Destination

ui

1

2

3

4

5

A

-40

-

-22

-33

0

0

B

-44

-

-

-

-

-4

C

-38

-28

-

-

-6

-40

-32

-22

-33

0

vj

Evaluation

of ui and

vj

Table

58

Origin

Destination

190

Operations

Research (MTH601)

191

1

2

3

4

5

A

-25

B

-35

-30

-30

0

C

-38

-30

0

Cost

of unalloted cells

Table

59

Origin

Destination

1

2

3

4

5

A

-32

B

-36

-26

-37

-4

C

-46

-39

-6

(ui +

vj) for

unalloted cells

Table

60

Origin

Destination

1

2

3

4

5

A

7

B

1

-4

7

4

C

8

9

6

Cell

Evaluation

The

matrix of cell evaluation of

cell evaluation in table 60

shows a negative entry in

the cell (B, 3)

indicating

that this is a potential

cell for allotment so that we

get a better result. Hence

we make a reallotment as

shown

by dotted lines in table

61.

Table

61

Origin

Destination

1

2

3

4

5

A

20

30

50

B

20

10

C

20

50

Reallotment

We

can conduct once again

the optimality test. One

more iteration would reveal

that the allotments

in

the

table 61 are optimal. This iteration is

left to the reader. Hence

the profit

=

(20

×

40)

+

(30

×

33)

+

(20

×

44)

+

(50

×

0)

+

(10

×

30)

+

(20

×

38)

+

(50

×

20)

=

Rs.5130.

191

Operations

Research (MTH601)

192

REVIEW

QUESTIONS

1.

Solve

the following transportation

problem for minimization

(Unit costs are given in

rupees).

Destination

Origin

D1

D2

D3

D4

D5

Supply

01

4

3

1

2

6

40

02

5

2

3

4

5

30

03

3

5

6

3

2

20

04

2

4

4

5

3

10

Demand

30

30

15

20

5

2.

A

manufacturer has distribution centres at

X, Y and Z. These centres

have availability of 40, 20

and 40

units

of the product, His retail

outlets at A, B, C, D and E require

25, 10, 20, 30 and 15

units

respectively.

The transport cost per

unit between each centre

and each outlet is given

below.

Retail

Outlets

Distribution

A

B

C

D

E

Centre

X

55

30

40

50

50

Y

35

30

100

45

60

Z

40

60

95

35

30

Determine

the optimal distribution to minimize

the cost of

transportation.

3.

(a)

A company has three

warehouses, W1,

W2 and

W3 and

four retail stores S1, S2,

S3 and

S4.

The

availability

of a given commodity at these

warehouses are as follows:

W1 = 14,

W2 = 16,

W3 = 5.

The

demands

at these stores are:

S1 = 6,

S2 = 10,

S3 = 15,

S4 = 4.

The costs of transporting

one unit of the

commodity

from warehouse i to store j, in

rupees, are given in the

following table.

S1

S2

S3

S4

6

4

1

5

W1

8

9

2

7

W2

4

3

6

2

W3

Determine

the optimum transportation

schedule, which minimizes

the total transportation

cost.

4.

A

firm manufacturing a single

product has three plants at

locations X,

Y and

Z.

The three plants

have

produced

60, 35 and 40 units

respectively during the

week. The firm has

made commitments to sell 22,

45,

20, 18 and 30 units of the

product to customers A,

B, C, D and

E

respectively.

The net per unit

cost

of

transporting from the three

plants to the five customers

is given in the table

below.

192

Operations

Research (MTH601)

193

Customers

Plant

Locations

A

B

C

D

E

X

4

1

3

4

4

Y

2

3

2

2

3

Z

3

5

2

4

4

Use

Vogel's approximation method to determine

the cost of shifting the

product from plant locations

to

the

customers. Does your

solution provide a least

cost transportation

schedule?

5.

A

steel company has three

furnaces and five rolling

mills. Transportation costs

(Rupees per quintal)

for

sending

steel from furnaces to

rolling mills are given in

the following table.

Rolling

Mills

Furnaces

M1

M2

M3

M4

M5

Availability

A

4

2

3

2

6

8

B

5

4

5

2

1

12

C

6

5

4

7

3

14

Required

4

4

10

8

8

How

should they meet the

requirement?

6.

A

company has three factories

at A, B and C, which supply

warehouses at D, E, F and G

respectively.

Monthly

product capacities of these

factories are 250, 300

and 400 units respectively.

The current

warehouse

requirements are 200, 275

and 300 units respectively.

Unit transportation costs

from

factories

to warehouses are given

below.

To

D

E

F

G

A

11

13

17

14

B

16

18

14

10

C

21

24

13

10

Determine

the optimum distribution to minimize

cost.

7.

Solve

the following transportation

problem for minimization,

the cost matrix is given

as:

D1

D2

D3

D4

D5

ai

01

12

4

9

5

9

55

02

8

1

6

6

7

45

03

1

12

4

7

7

30

04

10

15

6

9

1

50

40

20

50

30

40

b1

Find

all the alternate optimal

solutions.

8.

Solve

the following transportation

problem for

minimization.

To

I

II

III

IV

V

ai

20

19

14

23

16

40

A

193

Operations

Research (MTH601)

194

15

20

13

19

16

60

B

18

15

18

20

100

70

C

30

40

50

40

60

bj

9.

Pir

Iron and Steel Company

(PISCO) has three open

hearth furnaces and five

rolling mills.

Transportation

costs (Rs. per quintal) for

shipping steel from furnaces

to rolling mills are shown

in the

following

table.

Mills

Furnaces

M1

M2

M3

M4

M5

Capacities

4

2

3

2

6

8

F1

5

4

5

2

1

12

F2

6

5

4

7

7

14

F3

Required

4

4

10

8

8

What

is an optimal shipping schedule

for PISCO?

10.

A

company having plants at

P,

Q and

R

supplies

to the warehouses at W,

X, Y and

Z.

Monthly plant

capacities

are 75, 95, and

120 respectively. Monthly

warehouse requirements are

55, 65, 75 and

100

respectively.

Unit shipping costs are as

follows.

W

X

Y

Z

P

18

21

15

12

Q

16

22

26

15

R

16

15

16

17

Determine

the optimum distribution for

this company to minimize the

shipping costs using VAM

for

initial

solution.

11.

The

Products of three plants

F1,

F2 and

F3 are

to be transported to 5 warehouses

W1, W2,

W3, W4

and

W5. The

capacities of plants, the

requirements of ware houses

and the cost of

transportation are

indicated

in the following

table.

W1

W2

W3

W4

W5

Plant

Capacity

74

56

54

62

68

400

F1

58

64

62

58

54

500

F2

66

70

52

60

60

600

F3

Demand

200

280

240

360

320

Find

the optimum transportation

schedule and the associated

cost of transportation.

12.

Goods

are to be transported from

three warehouses to six

customers. The availabilities at

the

warehouses

are 100, 120 and

150 units respectively. The

demands of customers are 50,

40, 50, 90, 60

and

80 respectively. The unit

transportation costs are

given in the following

table.

C1

C2

C3

C4

C5

C6

15

25

18

35

40

26

W1

22

36

40

60

50

38

W2

26

38

45

52

45

48

W3

194

Table of Contents:

- Introduction:OR APPROACH TO PROBLEM SOLVING, Observation

- Introduction:Model Solution, Implementation of Results

- Introduction:USES OF OPERATIONS RESEARCH, Marketing, Personnel

- PERT / CPM:CONCEPT OF NETWORK, RULES FOR CONSTRUCTION OF NETWORK

- PERT / CPM:DUMMY ACTIVITIES, TO FIND THE CRITICAL PATH

- PERT / CPM:ALGORITHM FOR CRITICAL PATH, Free Slack

- PERT / CPM:Expected length of a critical path, Expected time and Critical path

- PERT / CPM:Expected time and Critical path

- PERT / CPM:RESOURCE SCHEDULING IN NETWORK

- PERT / CPM:Exercises

- Inventory Control:INVENTORY COSTS, INVENTORY MODELS (E.O.Q. MODELS)

- Inventory Control:Purchasing model with shortages

- Inventory Control:Manufacturing model with no shortages

- Inventory Control:Manufacturing model with shortages

- Inventory Control:ORDER QUANTITY WITH PRICE-BREAK

- Inventory Control:SOME DEFINITIONS, Computation of Safety Stock

- Linear Programming:Formulation of the Linear Programming Problem

- Linear Programming:Formulation of the Linear Programming Problem, Decision Variables

- Linear Programming:Model Constraints, Ingredients Mixing

- Linear Programming:VITAMIN CONTRIBUTION, Decision Variables

- Linear Programming:LINEAR PROGRAMMING PROBLEM

- Linear Programming:LIMITATIONS OF LINEAR PROGRAMMING

- Linear Programming:SOLUTION TO LINEAR PROGRAMMING PROBLEMS

- Linear Programming:SIMPLEX METHOD, Simplex Procedure

- Linear Programming:PRESENTATION IN TABULAR FORM - (SIMPLEX TABLE)

- Linear Programming:ARTIFICIAL VARIABLE TECHNIQUE

- Linear Programming:The Two Phase Method, First Iteration

- Linear Programming:VARIANTS OF THE SIMPLEX METHOD

- Linear Programming:Tie for the Leaving Basic Variable (Degeneracy)

- Linear Programming:Multiple or Alternative optimal Solutions

- Transportation Problems:TRANSPORTATION MODEL, Distribution centers

- Transportation Problems:FINDING AN INITIAL BASIC FEASIBLE SOLUTION

- Transportation Problems:MOVING TOWARDS OPTIMALITY

- Transportation Problems:DEGENERACY, Destination

- Transportation Problems:REVIEW QUESTIONS

- Assignment Problems:MATHEMATICAL FORMULATION OF THE PROBLEM

- Assignment Problems:SOLUTION OF AN ASSIGNMENT PROBLEM

- Queuing Theory:DEFINITION OF TERMS IN QUEUEING MODEL

- Queuing Theory:SINGLE-CHANNEL INFINITE-POPULATION MODEL

- Replacement Models:REPLACEMENT OF ITEMS WITH GRADUAL DETERIORATION

- Replacement Models:ITEMS DETERIORATING WITH TIME VALUE OF MONEY

- Dynamic Programming:FEATURES CHARECTERIZING DYNAMIC PROGRAMMING PROBLEMS

- Dynamic Programming:Analysis of the Result, One Stage Problem

- Miscellaneous:SEQUENCING, PROCESSING n JOBS THROUGH TWO MACHINES

- Miscellaneous:METHODS OF INTEGER PROGRAMMING SOLUTION