|

Transportation Problems:FINDING AN INITIAL BASIC FEASIBLE SOLUTION |

| << Transportation Problems:TRANSPORTATION MODEL, Distribution centers |

| Transportation Problems:MOVING TOWARDS OPTIMALITY >> |

Operations

Research (MTH601)

168

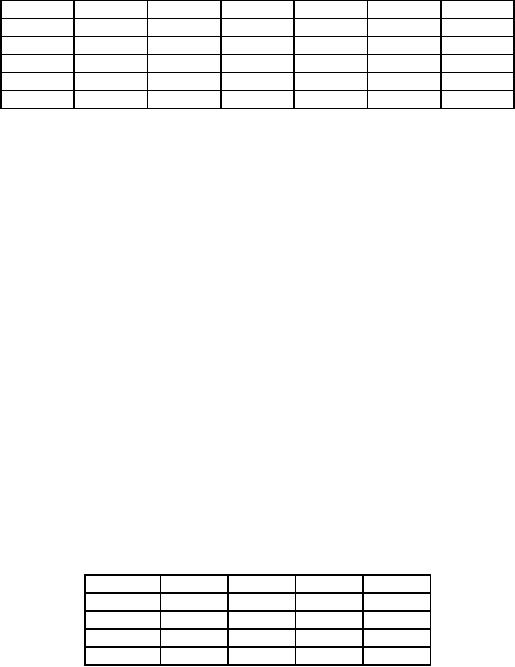

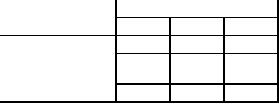

Table

4

Distribution

center

Plant

1

2

3

4

5

Supply

1

20

25

27

20

15

40

2

18

21

22

24

20

70

3

19

17

20

18

19

90

4

0

0

0

0

0

30

Demand

30

40

60

40

60

230

FINDING

AN INITIAL BASIC FEASIBLE

SOLUTION

An

initial basic feasible solution to a

transportation problem can be

found by any one of the

three

following

methods:

(i)

North west corner rule

(NWC)

(ii)

Least cost method

(LCM)

(iii)

Vogel's approximation method (VAM)

North

West Corner Rule

STEP

1 Start

with the cell in the

upper left hand corner

(North West Corner).

STEP

2 Allocate

the maximum feasible

amount.

STEP

3 Move

one cell to the right if

there is any remaining supply.

Otherwise, move one cell

down. If both are

impossible,

stop or go to step

(2).

An

example is considered at this

juncture to illustrate the application of

NWC rule.

Example

2

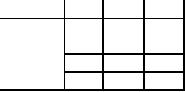

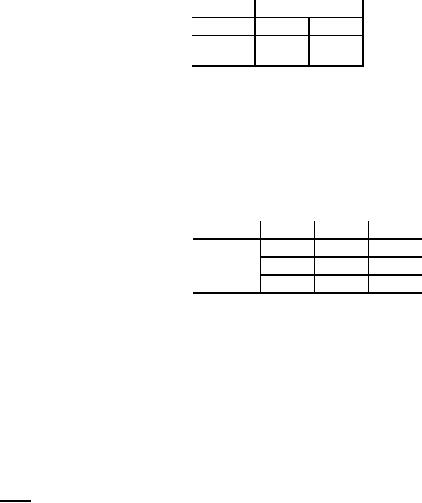

Table

5

Destinations

Origin

P

Q

R

Supply

A

5

7

8

70

B

4

4

6

30

C

6

7

7

50

Demand

65

42

43

150

In

table 5 supply level, demands at

various destinations, and

the unit cost of

transportation are given.

Use NWC

rule

to find the initial

solution.

Solution:

The

solution obtained by the North

West Corner Rule is a basic

feasible solution. In this

method we do

not

consider the unit cost of

transportation. Hence the solution

obtained may not be an optimal

solution. But this

will

serve as an initial solution,

which can be improved.

168

Operations

Research (MTH601)

169

We

give below the procedure for

the solution of the above

problem by NWC rule.

The

North West Corner cell

(AP) is chosen for allocation.

The origin A has 70 items

and the

destination

P requires only 65 items.

Hence it is enough to allot 65 items

from A to P. The origin A

which is

alive

with 5 more items can

supply to the destination to

the right is alive with 5

more items can supply to

the

destination

to the right of P namely Q whose

requirement is 42. So, we

supply 5 items to Q thereby

the origin A

is

exhausted. Q requires 37 items

more. Now consider the

origin B that has 30 items

to spare. We allot 30

items

to

the cell (BQ) so that

the origin B is exhausted.

Then move to origin C and

supply 7 more items to

the

destination

Q. Now the requirement of

the destination Q is complete

and C is left with 43 items

and the same

can

be alloted to the destination R.

Now the origin C is emptied

and the requirement at the

destination R is also

complete.

This completes the initial solution to

the problem.

The

above calculations are

performed conveniently in a table 6 as

shown below:

Table

6

Destinations

Origin

P

Q

R

A

65

5

70

65

0

B

30

30

0

C

7

43

50

7

43

0

65

42

43

0

37

0

0

The

total cost of transportation by this

method will be

65

×

5

+

5

×

7

+

30

×

4

+

7

×

7

+

43

×

7

=

Rs.

830.

As

the solution obtained by the

North West Corner Rule may

not be expected to be particularly close

to

the

optimal solution, we have to explore a

promising initial basic feasible

solution, so that we can

teach the

optimal

solution to the problem with

minimum number of

iterations.

169

Operations

Research (MTH601)

170

Least

Cost Method

STEP

1:

Determine the least cost

among all the rows of the

transportation table.

STEP

2:Identify

the row and allocate

the maximum feasible

quantity in the cell

corresponding to the least

cost

in

the row. Then eliminate that

row (column) when an allocation is

made.

STEP

3: Repeat

steps 1 and 2 for the

reduced transportation table

until all the available

quantities are

distributed

to the required places. If

the minimum cost is not

unique, the tie can be

broken arbitrarily.

To

illustrate, consider the example

repeated in table 7

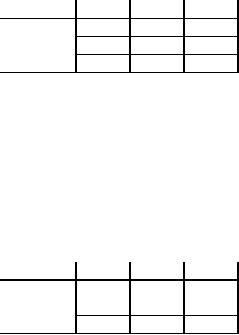

Table

7

Destination

Origin

P

Q

R

Supply

A

5

7

8

70

B

4

4

6

30

0

C

6

7

7

50

Demand

65

42

43

55

We

examine the rows A, B and C, 4 is

the least cost element in

the cell (B,P) and (B, Q)

and the tie can be

broken

arbitrarily. Select (B, P).

The origin B can supply 30

items to P and thus origin B

is exhausted. P still

requires

35 more units. Hence,

deleting the row B, we have

the reduced matrix as in the

table 8

Table

8

Destination

Origin

P

Q

R

Supply

35

A

5

7

8

70

35

C

6

7

7

50

Demand

35

42

43

0

In

the reduced matrix (table 8)

we observe that 5 is the

least element in the cell

(A, P) and examine the

supply at

A

and demand at P. The

destination P requires 35 items

and this requirement is

satisfied from A so that

the

column

P is deleted next. So we have

the reduce matrix as in

table 9

170

Operations

Research (MTH601)

171

Table

9

Destination

Origin

Q

R

Supply

35

A

7

8

35

0

C

7

7

50

Demand

42

43

7

In

the reduced matrix (table 9)

we choose 7 as least element

corresponding to the cell

(A. Q). We

supply

35 units from A to Q so have

the reduced matrix in

table10.

Table

10

Destination

Origin

Q

R

Supply

7

43

A

7

8

50

0

Demand

7

43

0

0

Now,

only one row is left

behind. Hence, we allow 7

items from C to Q and 43

items C to R.

We

now have the allotment as

per the least cost

method as shown in the table

11

Table

11

Destination

Origin

P

Q

R

Supply

A

35

35

70

B

30

30

C

7

43

50

Demand

65

42

43

The

cost of the allocation by the

least cost method is 35 x 5 + 35 x 7 + 30

x 4 + 7 x 7 + 43 x 7 = Rs. 890

Vogel's

Approximation Method

(VAM)

This

method is based on the

'difference' associated with

each row and column in the

matrix giving unit

cost

of transportation cij. This

'difference' is defined as the arithmetic

difference between the

smallest and next

to

the smallest element in that

row or column. This difference in a

row or column indicates the

minimum unit

171

Operations

Research (MTH601)

172

penalty

incurred in failing to make an allocation

to the smallest cost cell in

that row or column. This

difference

also provides a measure of

proper priorities for making allocations

to the respective rows and

column.

In

other words, if we take a

row, we have to allocate to

the cell having the

least cost and if we fail to

do so, extra

cost

will be incurred for a wrong

choice, which is called

penalty. The minimum penalty

is given by this

difference.

So, the procedure repeatedly

makes the maximum feasible

allocation in the smallest cost

cell of the

remaining

row or column, with the

largest penalty. Once an allocation is

fully made in a row or column,

the

particular

row or column is eliminated. Hence and

allocation already made cannot be

changed. Then we have

a

reduced

matrix. Repeat the same

procedure of finding penalty of

all rows and columns in the

reduced matrix,

choosing

the highest penalty in a row

or column and allotting as much as

possible in the least cost

cell in that

row

or column. Thus we eliminate another

fully allocated row or column,

resulting in further reducing

the size

of

the matrix. We repeat till

all supply and demand

are exhausted.

A

summary of the steps involved in Vogel's

Approximation Method is given

below:

STEP

1: Represent

the transportation problem in

the standard tabular

form.

STEP

2: Select

the smallest element in each

row and the next to the

smallest element in that

row. Find the

difference.

This is the penalty written on

the right hand side of each

row. Repeat the same

for each column. The

penalty

is written below each

column.

STEP

3:

Select the row or column

with largest penalty. If

there is a tie, the same

can be broken

arbitrarily.

STEP

4:

Allocate the maximum

feasible amount to the

smallest cost cell in that

row or column.

STEP

5:

Allocate zero else where in

the row or column where the

supply or demand is

exhausted.

STEP

6:

Remove all fully allocated

rows or columns from further

consideration. Then proceed

with the

remaining

reduced matrix till no rows or

columns remain.

Let

us apply Vogel's Approximation Method to

the above example as given

below in table12

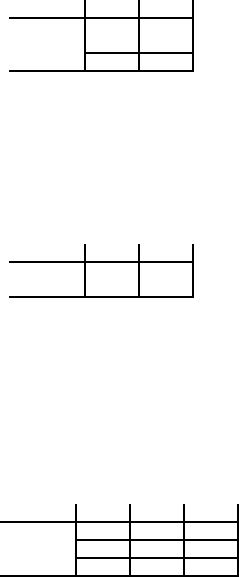

Table

12

Origin

Destination

Supply

Row

difference

P

Q

R

A

5

7

8

70

(2)

30

6

30

0

(0)

B

4

4

C

6

7

7

50

(1)

Demand

65

42

43

12

Column

difference (1)

(3)

(1)

Largest

Penalty

The

difference between the

smallest and next to the

smallest element in each row

and in each column is

calculated.

This is indicated in the

parenthesis. We choose the

maximum from among the

differences. The

first

individual

allocation will be to the smallest

cost of a row or column with

the largest difference. So we

select the

column

Q

(penalty

= 3) for the first

individual allocation, and

allocate to (B,

Q)

as much as we can, since

this

cell

has the least cost location.

Thus 30 units from B are

allocated to Q.

This exhausts the supply

from B.

However,

there is still a demand of 12

units from Q.

The allocations to other

cells in that column are 0,

as

indicated.

The next step is to write

down the reduced matrix

(as in table 13) eliminating

row B

(as

it is

exhausted).

172

Operations

Research (MTH601)

173

Table

13

Origin

Destination

Supply

Row

difference

P

Q

R

65

7

8

70

5

(2)

A

5

C

6

7

7

50

(1)

Demand

65

12

43

0

Column

difference (1)

(0)

(1)

From

the table 13, (2) is

the largest unit difference

corresponding to the row

A.

This leads to an allocation in the

corresponding

minimum cost location in row

A,

namely cell (A,

P).

The maximum possible allocation is

only 65

as

required by P

from

A

and

allocation of 0 to others in the row

A.

Column P

is

thus deleted and the

reduced

matrix

is given in table 14.

Maximum

difference is 1 in row A

and

in column C.

Select arbitrarily A

and

allot the least cost

cell (A,

Q)

5

units.

Delete row A.

Now,

we have only one row

C

and

two columns Q

and

R

(Table

15) indicating that all the

available amount

from

C

has

to be moved to Q

and

R

as

per their requirements.

Hence we have the table

15

Table

14

Origin

Destination

Supply

Row

difference

P

R

5

8

5

0

(1)

A

7

C

7

7

50

Demand

12

43

7

Column

difference

(0)

(1)

173

Operations

Research (MTH601)

174

Table

15

Destination

Supply

Origin

Q

R

7

43

50

0

C

7

7

7

43

0

0

Table

16

Destination

Origin

P

Q

R

Supply

A

65

5

70

B

30

30

C

7

43

50

Demand

65

42

43

We

obtain as our basic feasible

solution by re-tracking various positive

allocations in successive

stages.

We

have the solution by Vogel's

Approximation Method as shown in the

table 16

The

cost of allocation by Vogel's Approximation Method

will be

65

×

5

+

5

×

7

+

30

×

4

+

7

×

7

+

43

×

7

=

325

+

35

+

120

+

49

+

301

=

Rs.

830.

Note:

Cost

of allocation for the same

problem with three

methods:

NWC

method - Rs. 830/-

Least

cost method -

Rs.890/-

Vogel's

Approximation Method - Rs.

830/-

Generally

VAM gives a better initial

solution.

174

Operations

Research (MTH601)

175

REVIEW

QUESTIONS

1.

What

do you mean by transportation

problem?

2.

What

do you mean by feasible solution

and basic feasible solution of

transportation problem?

3.

Describe

Transportation problem. Give a method of

finding an initial feasible

solution.

4.

Explain

in brief with examples.

(i)

North West Corner

rule.

(ii)

Vogel's Approximation Method.

5.

Explain

the classical transportation

problem and write down

its mathematical formulation and

show

that

it is a particular case of a linear

programming problem.

6.

A

petroleum company has three

major oil fields and five

oil refineries. The shipping

costs from the

fields

to the refineries, fields are as

shown in the table.

Refinery

Capacity

Production

Refinery

Barrels

per day

Field

Barrels

per day

A

10,000

1

20,000

B

13,000

2

25,000

C

13,000

3

30,000

D

16,000

E

18,000

Cost

per Barrel (Rs.)

Field

A

B

C

D

E

1

400

300

330

380

360

2

350

350

380

320

350

3

370

300

400

350

340

Determine

the optimum scheme using

the North West Corner

Rule.

Determine

the optimum scheme using

the Least Cost

Method.

Determine

the optimum scheme using

Vogel's Approximation Method.

Compare

the computations

175

Table of Contents:

- Introduction:OR APPROACH TO PROBLEM SOLVING, Observation

- Introduction:Model Solution, Implementation of Results

- Introduction:USES OF OPERATIONS RESEARCH, Marketing, Personnel

- PERT / CPM:CONCEPT OF NETWORK, RULES FOR CONSTRUCTION OF NETWORK

- PERT / CPM:DUMMY ACTIVITIES, TO FIND THE CRITICAL PATH

- PERT / CPM:ALGORITHM FOR CRITICAL PATH, Free Slack

- PERT / CPM:Expected length of a critical path, Expected time and Critical path

- PERT / CPM:Expected time and Critical path

- PERT / CPM:RESOURCE SCHEDULING IN NETWORK

- PERT / CPM:Exercises

- Inventory Control:INVENTORY COSTS, INVENTORY MODELS (E.O.Q. MODELS)

- Inventory Control:Purchasing model with shortages

- Inventory Control:Manufacturing model with no shortages

- Inventory Control:Manufacturing model with shortages

- Inventory Control:ORDER QUANTITY WITH PRICE-BREAK

- Inventory Control:SOME DEFINITIONS, Computation of Safety Stock

- Linear Programming:Formulation of the Linear Programming Problem

- Linear Programming:Formulation of the Linear Programming Problem, Decision Variables

- Linear Programming:Model Constraints, Ingredients Mixing

- Linear Programming:VITAMIN CONTRIBUTION, Decision Variables

- Linear Programming:LINEAR PROGRAMMING PROBLEM

- Linear Programming:LIMITATIONS OF LINEAR PROGRAMMING

- Linear Programming:SOLUTION TO LINEAR PROGRAMMING PROBLEMS

- Linear Programming:SIMPLEX METHOD, Simplex Procedure

- Linear Programming:PRESENTATION IN TABULAR FORM - (SIMPLEX TABLE)

- Linear Programming:ARTIFICIAL VARIABLE TECHNIQUE

- Linear Programming:The Two Phase Method, First Iteration

- Linear Programming:VARIANTS OF THE SIMPLEX METHOD

- Linear Programming:Tie for the Leaving Basic Variable (Degeneracy)

- Linear Programming:Multiple or Alternative optimal Solutions

- Transportation Problems:TRANSPORTATION MODEL, Distribution centers

- Transportation Problems:FINDING AN INITIAL BASIC FEASIBLE SOLUTION

- Transportation Problems:MOVING TOWARDS OPTIMALITY

- Transportation Problems:DEGENERACY, Destination

- Transportation Problems:REVIEW QUESTIONS

- Assignment Problems:MATHEMATICAL FORMULATION OF THE PROBLEM

- Assignment Problems:SOLUTION OF AN ASSIGNMENT PROBLEM

- Queuing Theory:DEFINITION OF TERMS IN QUEUEING MODEL

- Queuing Theory:SINGLE-CHANNEL INFINITE-POPULATION MODEL

- Replacement Models:REPLACEMENT OF ITEMS WITH GRADUAL DETERIORATION

- Replacement Models:ITEMS DETERIORATING WITH TIME VALUE OF MONEY

- Dynamic Programming:FEATURES CHARECTERIZING DYNAMIC PROGRAMMING PROBLEMS

- Dynamic Programming:Analysis of the Result, One Stage Problem

- Miscellaneous:SEQUENCING, PROCESSING n JOBS THROUGH TWO MACHINES

- Miscellaneous:METHODS OF INTEGER PROGRAMMING SOLUTION