|

SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE |

| << METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method |

| SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE >> |

Chapter

- 4

SYNTHESIS

OF MATERIALS BASED ON SOLUBILITY

PRINCIPLE

C.

M. Janet

1.

INTRODUCTION

Fundamental

to the success of materials

science and technology is the

availability of

high-quality

materials exhibiting specific

tailor-made properties together

with an

appropriate

shape and microstructure. Solution

based methods especially

water based

mathods

offer numerous advantages. Cheap and

easy to handle precursors,

low cost,

simple

equipments, low energy input

and the eco-friendly nature

are few of them.

Moreover

they allow the easy

tailoring of synthesis parameters

throughout the whole

process,

which may be exploited to

achieve a more precise

control of composition,

shape

and

size of the resulting material. Since

the synthesis route

determines the properties of

the

material, the preparation

method chosen is very important

when designing

materials

for

specific applications. Wet

chemical routes for the

synthesis of nanostructures are

a

valuable

alternative to conventional processing and

gas phase synthesis, with

known

commercial

applications. Solvothermal methods and

hydrothermal methods

are

extensively

used in the synthesis of

materials of novel shape and

properties. The

majority

of

the metal organic frameworks

reported to date have been

synthesized using

solution

based

methods under bench-top

conditions (20-80 °C, 1

atm). Hydrothermal

synthesis

especially

has the attraction that it

favors the condensation of M-OH

into M-O-M bonds,

allowing

the preparation of materials

with multidimensional metal-oxygen

frameworks

[1].

Recognizing that most metal

salts are preferentially soluble in

polar solvents, for

example,

water, and that the opposite is

true for many organic

reactants, utilizing a higher

temperature

and biphasic solvothermal method

appears advantageous for

synthesizing

many

classes of hybrid materials.

Reaction at the interface of

two immiscible solvents

is

a

common technique for

crystallizing compounds at low to

moderate temperatures (<100

°C)

and is commonly used to prepare

hybrid inorganic-organic materials, in

addition to

other

products. The use of

biphasic solvothermal synthesis

has a number of

attractions

over

conventional hydro-/solvothermal methods.

The basic concept that

underlies in wet

4.2

Synthesis

of Materials Based on Solubility

Principle

chemical

methods or solvothermal methods

are the principles of

solubility. Hence, it is

important

to have a clear understanding of

the fundamentals of solubility to

that its use in

synthetic

procedures.

2.

BASICS OF SOLUBILITY

A

solution is a homogeneous mixture of two

or more substances. One of

the substances is

called

a solvent (a substance in which

other substance or substances

are dissolved). The

substances

dissolved in a solvent are

called solutes. A solution can

exist in a solid,

liquid

or

gas form depending on mixed

substances and external conditions

such as temperature

and

pressure. According to a chemists'

perspective solubility can be understood

as a

maximum

amount of solute that can

dissolve in a solvent at so called

equilibrium. In

chemistry,

equilibrium is a state where reactants

and products reach a balance which

means

that no more solute can be

dissolved in the solvent in

the set conditions

(temperature,

pressure). Such a solution is called a

saturated solution. There are

two

groups

of substances in case of which

solubility measure cannot be

applied. These are

miscible

and immiscible substances. Some

solvents, like water and

alcohol, can be mixed

together

and create a homogenous phase in

any proportion. A solubility

measure cannot

be

applied to such two

substances. Such substances

are called miscible. On the

other hand

if

two substances cannot be

mixed together (like water

and oil), they are

called

immiscible

[2].

In

the process of dissolving,

molecules of the solute are

inserted into a solvent

and

surrounded

by its molecules. For this

process to take place, molecular bonds

between

molecules

of solute as well as that of

solvent have to be disrupted.

Both of these require

energy.

For example when sugar

dissolves in water, new bonds

between sugar and water

are

created. During this process

energy is given off. The

amount of this energy

is

sufficient

to break bonds between molecules of sugar and

between molecules of

water.

This

example is relevant to any

solute and solvent. If the bonds

between the solvent

and

solute

are too strong and there is

not enough energy provided

to break them while

dissolving,

the solute will not

dissolve. The same energy

rule can be applied to salts.

Salts

composed

of positive and negative ions

which are bound together by

the force of

attraction

of their opposite charges. In cases where

energy needed to break their

ionic

Synthetic

Strategies in Chemistry

4.3

bonds

is lower, the dissolution of salts can

take place only if the sufficient

energy is given

off

by an interaction of the ions

with solvent.

Salts

that are considered to be soluble

are Group I and ammonium

(NH4+)

compounds,

nitrates, acetates, chlorides,

bromides and iodides (except: silver

(Ag+),

lead

2+

(II)

(Pb2+),

mercury (I) (Hg2

),

copper (Cu+)

halides) and sulphates (except:

Silver

(Ag+), lead

(Pb2+), barium (II) (Ba2+),

strontium (II) (Sr2+) and

calcium(II) (Ca2+) ).

Those

which

are insoluble are carbonates

except Group I, ammonium

(NH4+) and

uranyl

compounds,

sulfites except Group I and

NH4+ compounds, phosphates

except Group I

and

NH4+ compounds, hydroxides and

oxides except Group I, NH4+,

barium (Ba2+),

strontium

(Sr2+)

and thallium (Tl+) and

sulfides except Group I,

Group II and NH4+

compounds.

The solubility principle

that holds well in the

case of organic compounds

is

"Like

dissolves like".

3.

SOLUBILITY PRODUCT (K SP)

Solubility

product constant is a simplified

equilibrium constant (Ksp)

defined for

equilibrium

between a solid and its respective

ions in a solution. Its

value indicates the

degree

to which a compound dissociates in

water. The higher the

solubility product

constant,

the more soluble the

compound is. The expression

for Ksp for a salt is

the

product

of the concentrations of the

ions, with each

concentration raised to a power

equal

to

the coefficient of that ion

in the balanced equation for

the solubility

equilibrium.

Solubility

product constants are used

to describe saturated solutions of ionic

compounds

of

relatively low solubility. A saturated

solution is in a state of dynamic

equilibrium

between

the dissolved, dissociated, ionic

compound and the undissolved

solid. For Silver

chloride

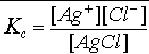

Kc is

given in the following

equation.

------------------

(1)

Where

[Ag+]

and [Cl-]

reperesent concentrations of ions of

Ag+ and Cl-

and [AgCl] is

a

value

representing the amount of

moles in a liter of solid

AgCl. [AgCl] is a constant

and

therefore,

the equation can be written

as

Kc

[AgCl] = [Ag+]

[Cl-]

---------------------

(2)

4.4

Synthesis

of Materials Based on Solubility

Principle

The

product of equilibrium concentartions of

Ag+ and

Cl- is equal to a constant.

This

constant

is called as solubility product

constant or Ksp [3].

3.1

Significance of Le Chatelier's Principle

in Solubility Concept

Once

a system has reached

equilibrium, the relative

concentrations or pressures of

the

species

in the reaction do not change.

However, if you disturb the

system in some way,

the

equilibrium will adjust until a

new equilibrium is established. Le

Chatelier's principle

states

that "If a system at equilibrium is

disturbed by a change in temperature,

pressure,

or

the concentration of one of the

components, the system will

shift its equilibrium

position

so as to counteract the effect of

the disturbance". The ionic

product (IP) is

simply

a measure of the ions present in

the solvent. This may

sound trivial but, in fact,

it

is

not always straightforward and

the concept opens up a

number of interesting

features

of

how salts behave in solution. The

product of the soluble ions

of a salt in solution is

called

the ionic product. The

solubility product (Ksp) is

the ionic product when

the

system

is in equilibrium. When the

ionic product exceeds the

solubility product,

precipitation

will happen according to the Le

Chatelier's principle. From

equation (2) this

can

be understood. Any kind of precipitation

is thus governed by the

Lechatlier principle.

One

of the day to day

significance of ionic and solubility

products are that they

are the

important

basic

chemical

phenomena

underpinning

the

tooth

mineralisation,

demineralisation

and stability. Addition of a common

ion affects the ionic

product. This

has

important implications in the

mouth since the concentration of

calcium and phosphate

ions

in saliva and plaque fluid can be

influenced by external factors.

Solubility principles

in

the case of gases are

quite different from that of

solids and liquids. As the

materials of

interest

are mostly in solid state

the solubility principles of

gases are not dealt

here.

3.2

Temperature and Pressure

Effects on Solubility

Heat

+ Solid sugar + Water = Dissolved sugar

------------ (3)

The

equation (3) represents two

processes: dissolution going

left to right, and

crystallization

going right to left. When

the sugar crystals are

dissolving at exactly

the

same

rate that sugar is crystallizing out of

solution, the system is at

equilibrium. The

balance

between dissolution and crystallization

can be changed by changing the

Synthetic

Strategies in Chemistry

4.5

temperature

of the solution. Adding heat will

favor dissolution. Cooling

the solution will

favor

crystallization.

The

temperature dependence of solubility is

also usually explained using Le

Chatelier's

principle.

Le Chatelier's principle predicts

that heating the solution

mixture will shift

the

equilibrium

in favor of dissolution, to remove

the added heat. This

explains why sugar is

more

soluble in hot water than in

cold. The solubility of a

substance is its

concentration

in

a saturated solution. Substances with

solubilities much less than

1 g/100 mL of solvent

are

usually considered insoluble. The

solubility is sometimes called

"equilibrium

solubility"

because the rates at which

solute dissolves and is deposited

out of solution are

equal

at this concentration.

The

solubility of solutes is dependent on

temperature. When a solid

dissolves in a

liquid,

a change in the physical state of

the solid analogous to

melting takes place. Heat

is

required

to break the bonds holding the

molecules in the solid

together. At the same

time,

heat

is given off during the

formation of new solute-solvent

bonds.

(a)

Decrease in Solubility with

Temperature:

If

the heat given off in the

dissolving process is greater than

the heat required to break

apart

the solid, the net

dissolving reaction is exothermic

(energy given off). The

addition

of

more heat (increases temperature)

inhibits the dissolving

reaction since excess heat is

already

being produced by the

reaction. This situation is

not very common where

an

increase

in temperature produces a decrease in

solubility.

(b)

Increase in solubility with

Temperature

If

the heat given off in the

dissolving reaction is less

than the heat required to break

apart

the

solid, the net dissolving

reaction is endothermic (energy

required). The addition

of

more

heat facilitates the dissolving

reaction by providing energy to break

bonds in the

solid.

This is the most common

situation where an increase in

temperature produces an

increase

in solubility for

solids.

The

use of first-aid instant

cold packs is an application of

this solubility principle.

A

salt

such as ammonium nitrate is

dissolved in water after a sharp

blow breaks the

containers

for each. The dissolving

reaction is endothermic - requires

heat. Therefore the

heat

is drawn from the

surroundings, the pack feels

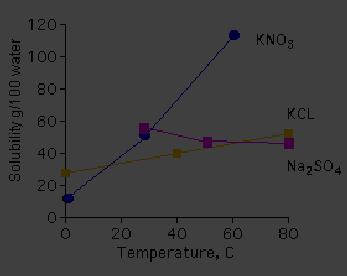

cold. The Fig. 4.1

represents the

4.6

Synthesis

of Materials Based on Solubility

Principle

effect

of temperature on the solubility of

three different salts.

Solubility of nitrate salt

of

K

is more compared to that of chlorides as

the temperature

increases.

Fig.

4.1. Temperature dependence of

solubility of different salts (ref.

2)

4.

HETEROGENEOUS EQUILIBRIA AND PRECIPITATION

Phase

transitions such as sublimation,

deposition, melting, solidification,

vaporization,

and

condensation are heterogeneous

equilibria, so are the

formation of crystals from

a

saturated

solution, because a solid and

its solution are separated

phases. The

equilibrium

constants

for saturated solution and solid

formation (precipitate) are

already defined as

solubility

product, Ksp. For

unsaturated and supersaturated solutions,

the system is not at

equilibrium,

and ion products, Qsp, which have

the same expression as

Ksp

is

used.

An

oversaturated solution becomes a

saturated solution by forming a solid to

reduce

the

dissolved material. The

crystals formed are called a

precipitate. Often, however,

a

precipitate

is formed when two clear

solutions are mixed. For

example, when a

silver

nitrate

solution and sodium chloride

solution are mixed, silver

chloride crystals

AgCl(s)

(a

precipitate) are formed.

Na+ and

NO3- are by-stander

ions.

Ag+(aq) + Cl-(aq) → AgCl(s)

(precipitate)

Silver

chloride is one of the few

chloride that has a limited

solubility. A precipitate is also

formed

when sodium carbonate is added to a

sample of hard water,

Ca2+(aq) + CO32-(aq) → CaCO3(s)

(precipitate).

Synthetic

Strategies in Chemistry

4.7

4.1

Solubility Products, Ksp,

and Ion Products Qsp

Formations

of precipitates are chemical

equilibria phenomena, and we usually

write these

heterogeneous

equilibrium in the following

manner, and call the

equilibrium constants

solubility

products, Ksp. If the

solution is not saturated, no precipitate

will form. In this

case,

the product is called the

ion product, Qsp.

4.2

Qsp, Ksp and

Saturation

For

some substances, formation of a

solid or crystallization does

not occur

automatically

whenever

a solution is saturated. These substances

have a tendency to form

oversaturated

solutions.

For example, syrup and honey

are oversaturated sugar solutions,

containing

other

substances such as citric

acids. For oversaturated

solutions, Qsp

is greater than

Ksp.

When

a seed crystal is provided or

formed, a precipitate will form

immediately due to

equilibrium

of requiring Qsp

to approach Ksp.

Sodium

acetate trihydrate,

NaCH3COO.3H2O,

when heated to 370 K will become

a

liquid.

The sodium acetate is said

to be dissolved in its own

water of crystallization.

The

substance

stays as a liquid when cooled to

room temperature or even

below 273 K. As

soon

as a seed crystal is present,

crystallization occur rapidly. In

such a process, heat is

released,

and the liquid feels warm.

Thus, the relationship among

Qsp, Ksp

and

saturation

is

given below [3]:

Qsp

< Ksp Unsaturated

solution

Qsp

= Ksp Saturated solution

Qsp

> Ksp Oversaturated

solution

5.

NANOPARTICLES THROUGH HOMOGENEOUS

NUCLEATION

For

the formation of nanoparticles by

homogeneous nucleation, a supersaturation

of

growth

species must be created. A reduction in

temperature of an equilibrium

mixture,

such

as saturated solution would lead to

supersaturation. Formation of metal

quantum

dots

in glass matrix by annealing at moderate

temperatures is a good example of

this

approach.

Another method is to generate a

supersaturation through in

situ chemical

reactions

by converting highly soluble

chemicals into less soluble

chemicals. For

example

semiconductor nanoparticles are

commonly produced by pyrolysis

of

organometallic

precursors. Nanoparticles can be

synthesized through homogeneous

4.8

Synthesis

of Materials Based on Solubility

Principle

nucleation

in three mediums: liquid,

gas and solid: however, the

fundamentals of

nucleation

and subsequent growth processes are

essentially the same. Before

discussing

the

detailed approaches for the

synthesis of uniformly sized monodispersed

nanoparticles,

it

is essential to review the fundamentals

of homogeneous nucleation and subsequent

growth

[4].

5.1

Fundamentals of Homogeneous

Nucleation

When

concentration of a solute in a solvent

exceeds its equilibrium

solubility or when

temperature

decreases below the phase

transformation point, a new

phase appears. A

solution

with solute exceeding the

solubility or supersaturation possesses a

high Gibbs

free

energy. The overall energy

of the system will be reduced by segregating

solute from

the

solution.

Fig.

4. 2. Nucleation and subsequent growth

(ref. 4)

When

the concentration of a solute

increases as a function of time no

nucleation would

occur

even above the equilibrium

solubility. Nucleation occurs

only when the

supersaturation

reaches a certain value above

the solubility. Homogeneous

nucleation is

important

for the formation of

particles of uniform size and

shape.

5.2

Examples of Nucleation

Pure

water freezes at -42 ° C rather than at

its freezing temperature of 0 ° C if no

crystal

nuclei,

such as dust particles, are

present to form an ice nucleus. Presence

of cloud

condensation

nuclei is important in meteorology

because they are often in

short supply in

the

upper atmosphere.

Synthetic

Strategies in Chemistry

4.9

Fig.

4.3. Nucleation of carbon

dioxide bubbles around a

finger (ref. 5)

Nucleation

in boiling can occur in the

bulk liquid if the pressure

is reduced so that the

liquid

becomes superheated with respect to

the pressure-dependent boiling point.

More

often

nucleation occurs on the

heating surface, at nucleation sites.

Typically, nucleation

sites

are tiny crevices where

free gas-liquid surface is

maintained or spots on the

heating

surface

with lower wetting

properties. Substantial superheating of a

liquid can be

achieved

after the liquid is

de-gassed and if the heating surfaces

are clean, smooth and

made

of materials well wetted by

the liquid. The creation of

a nucleus implies the

formation

of an interface at the boundaries of the

new phase. Some energy is

consumed

to

form this interface, based

on the surface energy of

each phase. If a

hypothetical

nucleus

is too small, the energy

that would be released by

forming its volume is

not

enough

to create its surface, and

nucleation does not proceed.

The critical nucleus

size

can

be denoted by its radius, and it is when

r=r* (or r critical) that

the nucleation

proceeds

[5].

6.

SOLUBILITY AND CRYSTAL GROWTH

Crystal

formation is made up of three

phases: nucleation, growth, and

cessation of

growth.

During nucleation, the

slowest and most difficult

phase in crystal growth,

the

smallest

crystal capable of growth

forms. The barrier to

formation of these

smallest

crystals

results from differences in

the stability between

molecules at the core and those

on

the surface of the crystal.

During nucleation, the

average stability of a molecule in

a

crystal

is very low because the

attraction between the

molecule and the crystal is

often

less

than that between the

molecule and the solvent.

Thus, it is significantly easier

to

4.10

Synthesis

of Materials Based on Solubility

Principle

successfully

stimulate the birth of a

crystal by introducing a smaller

crystal (seeding)

than

by

merely supersaturating a solution.

Once nucleation has been

accomplished, the

growth

phase

of crystal formation begins, a phase

characterized by the addition of

molecules to

the

existing crystal. Two opposing

forces impact this process:

enthalpy and entropy.

Growth

of a crystal reduces the

entropy (a measure of randomness) of

the system because

a

molecule free in solution

has greater entropy than one

tethered to a crystal's

growing

surface.

Although entropy favors

dissolution of crystals, it is

energetically favorable for

a

molecule

to be added to a crystal. Above a

critical saturation point,

enthalpy overcomes

entropy,

and crystal formation can

occur.

6.1

Crystal Kinks and

Ledges

In

addition to temperature and

concentration, the geometry of a

growing crystal's

surface

influences

growth. Imagine a spherical

molecule approaching a planar

surface of a

crystal.

In this case, the addition

of the molecule is not

energetically favorable

because

there

is only one point of contact.

Next, consider a spherical

molecule approaching a

"ledge"

surface of a crystal. In this

case, the addition of the

molecule is more

energetically

favorable because the

molecule is stabilized by two

points of contact at

which

intermolecular forces hold

the molecule to the crystal.

In the third case, the

"kink"

structure

provides three points of

contact. The kink structure

is the ideal surface

geometry

for

crystal growth. Because

kinks are sparse on a

crystal's surface, the

addition of even a

small

amount of impurities that

effectively clog the kink

sites is capable of killing

crystal

growth.

In order for crystal growth

to be maintained, "ledges" or kinks

must remain

available

for molecules to be added to

the crystal. At one point in

the field of crystal

research,

scientists observed that nucleation

occurs too quickly to be

explained solely by

the

addition of molecules to a planar

crystal surface. As a result,

the spiral

dislocation

(SD)

theory arose, stating that

molecules are added to the

surface of a crystal in a

manner

resulting

in the creation of new

ledges or kinks so that

crystal growth can continue.

With

the

development of atomic force

microscopy (AFM) for

physically detecting changes

in

depth

on the atomic scale, it was possible to

study changes associated

with a ledge on a

crystal.

To observe crystal formation, the

lab uses an atomic force

microscope to gather

data

on the movement of ledges as

organic crystals grow and

dissolve. This method

allows

the investigator to observe the rate and

geometry of ledge movement at

various

Synthetic

Strategies in Chemistry

4.11

concentrations

of solute and in the presence of

impurities. It was noticed that

dissolution

is

not exactly the opposite of

growth. During dissolution,

the ledges are smooth

and

regular,

while they are rough and

irregular during growth.

Although there are

several

theories

on how the irregularity may

be conducive to crystal growth,

the differences have

not

been fully explained.

6.2

Practical Significance of Solubility

and Crystal Growth

Understanding

the growth and dissolution of

crystals is valuable in a variety of

contexts.

Crystallization

is an effective and economical

purification process, and, in

some cases

where

substances cannot be purified by

distillation, it is the only

practical method.

More

importantly,

approximately eighty percent of

all pharmaceutical agents

are pure

crystalline

solids. Understanding the

dissolution of a particular crystalline

drug could

allow

chemists to alter the drug's

dissolution rate. Moreover, understanding

the

conditions

of crystallization may allow

chemists to predict whether

drugs crystallize

within

the body. In 2004, the

journal Heart reported a

case of a large crystal

forming in

the

heart of woman given a

continuous dose of a drug

for ventricular tachycardia.

A

better

understanding of this drug's

crystallization could have

prevented the

incident.

Clearly,

much of this research is not

yet crystal-clear.

7.

SOLUTION BASED SYNTHETIC

STRATEGIES

Solution

based synthetic strategies

involve mainly sol gel

process, hydrothermal

synthesis,

solvothermal synthesis and reduction in

solution. Among which

solvothermal

synthesis

and hydrothermal synthesis are

discussed in detail in the present

chapter.

7.1

Solvothermal Synthesis

Solvothermal

synthesis utilizes a solvent

under pressures and temperatures above

its

critical

point to increase the

solubility of solid and to speed up

reaction between

solids.

Most

materials can be made soluble in

proper solvent by heating and

pressuring the

system

close to its critical point.

This method allows the

easy control on the

solubility of

a

solute. And it leads to

lower super saturation state

which is necessary for

the

precipitation

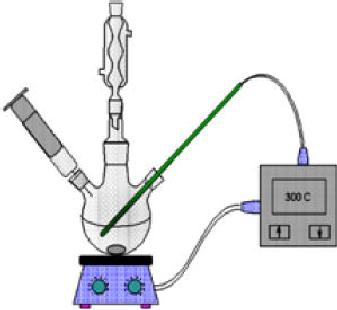

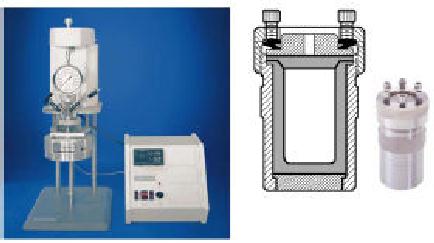

to happen. The reaction set-up

used for solvothermal

synthesis is given in

Fig.

4.4.

4.12

Synthesis

of Materials Based on Solubility

Principle

Fig.

4.4. Solvthermal synthesis

set-up (ref. 6)

7.1.1

Synthesis of Semiconductor

Chalcogenides

In

general, semiconductor chalcogenides of

different sizes and shapes

are prepared using

solvothermal

synthesis. In our laboratory we

have synthesized CdS

nanostructures

especially

nanorods through solvothermal

synthesis using a solid

precursor CdC2O4.

The

reagent

used to precipitate CdS was

(NH4)2S. The

reaction observed was represented

in

the

equation 6. Here the solvent

used was ethylene glycol and

the reaction

temperature

was

60 °C

and the reaction was carried

under a constant flow of an

inert gas [7].

CdC2O4

+ (NH4)2S

CdS

+ (NH4)2C2O4

----------

(6)

CdC2O4

is an

insoluble solid and (NH4)2S was liquid.

But the solvothermal

synthesis at

low

temperatures allowed in this case a

slow replacement reaction of

the ligand forming

the

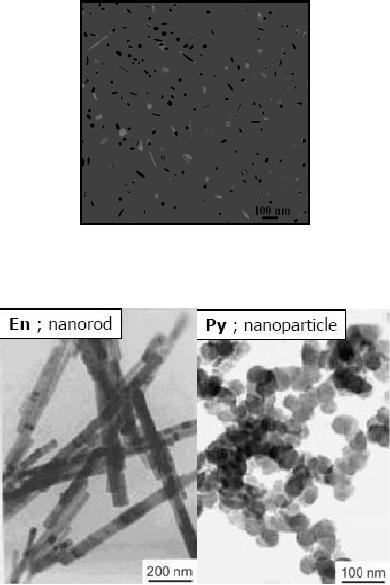

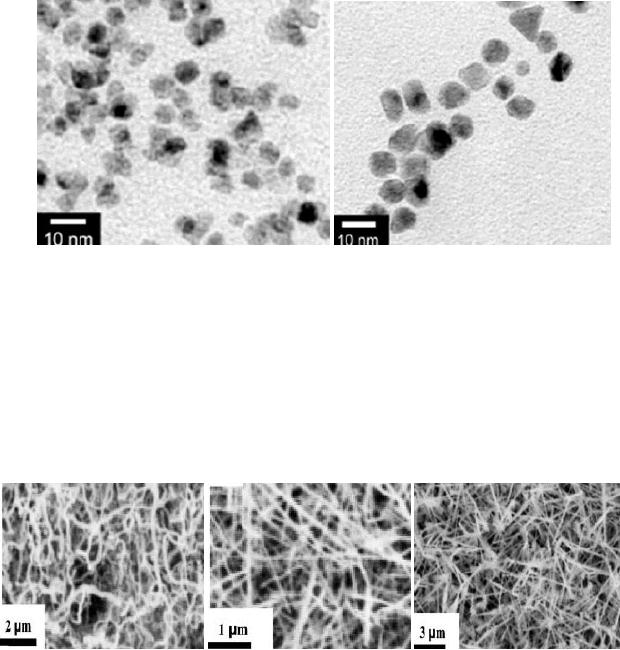

nanostructures of CdS. The TEM images of

the CdS nanorods are

given in the Fig.

4.5.

By changing the solvents,

temperature and the precursor

variety of sizes and

shapes

can

be produced through this

method. When ethylene

diamine is used the material

formed

was

also found to be nanorods with

high aspect ratio. But,

when pyridine was used

CdS

nanoparticles

are only formed.

Synthetic

Strategies in Chemistry

4.13

Fig.

4.5. TEM image of CdS prepared

from CdC2O4 using

solvothermal method in

ethylene

glycol (ref. 7)

Fig.

4.6. TEM image of CdS prepared

from CdC2O4 using solvothermal method

in

ethylene

diamine and pyridine (ref.

6)

7.1.2

Synthesis of Metal

Nanoparticles

Pt

and Pd nanoparticles were synthesized by

microwave-assisted solvothermal

method.

The

only difference is the

heating source is microwave. PVP with an

average molecular

weight

of 40'000 was used as a capping agent in

the experiments. H2PtCl6,

and

Palladium(II)2,4-pentanedionate

were used as metal

precursors. PVP was dissolved in

methanol

or ethanol and then the

metal salts were added. The

reactants were heated

for

60

min at 90 ºC when

methanol was used as a reducing agent and

at 120 ºC

when

ethanol

was used as a reducing agent for 60

min under microwave

irradiation [8].

4.14

Synthesis

of Materials Based on Solubility

Principle

Fig.

4.7. TEM images of the

obtained Pt and Pd nanoparticles

under

microwave-assisted

solvothermal conditions (ref.

8).

7.1.3

Synthesis of Metal Nitrides

and Oxides

In

another approach single source precursors of

halides of Al, Ga and In were

prepared

with

urea complexation and further

solvothermal synthesis at higher

temperatures

resulted

in the formation of the

respective nitrides. These nitrides

are of special relevance

in

photovoltaic applications

[9].

(a)

(b)

(c)

Fig.

4.8. TEM images of (a) AlN

(b) GaN (c) AlN nanowires

formed during

solvothermal

synthesis

(ref. 9).

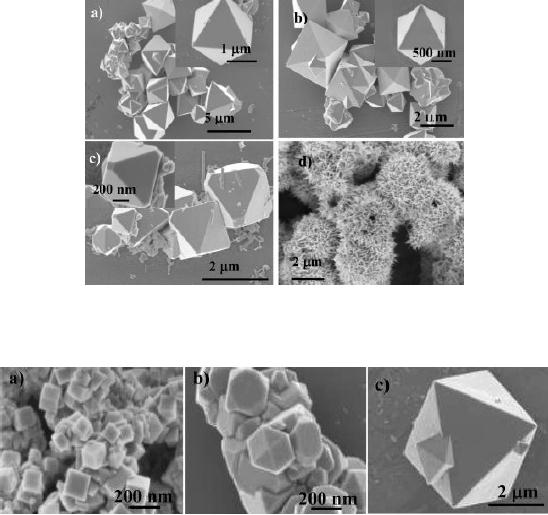

A

new and facile route was developed by

Suib et al., to manipulate

the growth of

hierarchically

ordered Mn2O3 architectures via a

solvothermal approach. Various

solvents

are

employed to control the

product morphologies and structures.

Mn2O3

with

unique

cuboctahedral,

truncated-octahedral, and octahedral

shapes are obtained. In a

typical

synthesis

Mn(NO3)2 was dissolved in an organic

solvent followed by a vigorous

stirring

at

room temperature for half an

hour in a Teflon liner. Then

the Teflon liner was

transferred

and sealed in an autoclave for

solvothermal treatment at 120 °C for 20

h. A

Synthetic

Strategies in Chemistry

4.15

variety

of different solvents was used to

investigate the effect of

solvents on the

morphology

of the resultant Mn2O3.

In order to investigate the

development of Mn2O3

crystals,

the reactions were also

conducted at different temperatures using

ethanol as the

solvent.

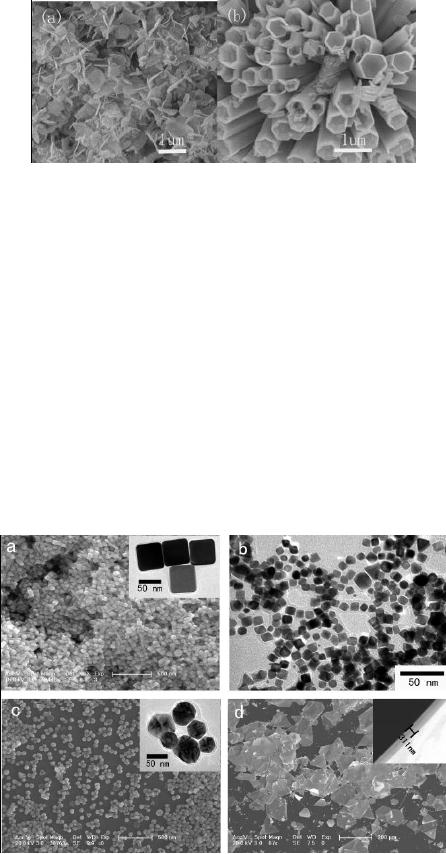

FESEM images of the Mn2O3

synthesized in

different solvents and for

different

duration

are given in Fig. 4.9 and

Fig. 4.10 respectively. The

images indicate the

shape

evolution

of Mn2O3 polyhedra. Mn2O3

is used in

catalytic as well as

electrocatalytic

applications

[10].

Fig.

4.9. FESEM images of

products synthesized in

different

solvents:

(a) ethanol, (b) 1-butanol,

(c) 2-butanol, and (d)

acetone (ref. 10).

Fig.

4.10. FESEM images of

products synthesized under

different

reaction

periods (a) 1.5 h, (b) 2 h, and

(c) 3 h (ref. 10).

7.2

Hydrothermal Synthesis

Hydrothermal

synthesis as the name indicates

the solvent is always water.

If liquid water

is

placed in an open container, its

temperature cannot be raised above 100

°C. But, if

water

is heated in a sealed container, it can

be heated to temperatures above 100 °C

which

means that supercritical

properties of the water can be

utilized under this

4.16

Synthesis

of Materials Based on Solubility

Principle

condition.

The advantages of inducing

supercritical behavior in hydrothermal

synthesis

are

that it will provide a single

phase behavior and give enhanced

permeability, mass

transport

capability and dissolving capacities.

Hydrothermal synthesis can be defined as

a

method

of synthesis of single crystals

which depends on the

solubility of minerals in

hot

water

under high pressure. Hydrothermal

synthesis is a century old

synthetic strategy and

it

was used for the synthesis

of minerals in general. From

80's hydrothermal method

was

utilized

extensively for newer

material synthesis. Advantages of

hydrothermal synthesis

are

in this method no post-heat

treatment is needed and hence

agglomeration will be less.

After

preparation no milling is required

which will reduce impurities. Any

complex

chemical

compositions can be synthesized by using

this method. Particle size or

shapes

can

be controlled in this approach. It can

induce self assembly leading

to newer and

complex

architectures of materials and the

precursors used are relatively

cheap raw

materials.

And hydrothermal method

crystal growth includes the

ability to create

crystalline

phases which are not stable

at the melting point. Also,

materials which have

a

high

vapour pressure near their

melting points can be grown by

the hydrothermal

method.

The

method is also particularly suitable

for the growth of large

good-quality crystals

while

maintaining good control over

their composition. Disadvantages of the

method

include

the need of expensive

autoclaves, good quality seeds of a

fair size and the

impossibility

of observing the crystal as it

grows. Fig. 4.11 shows

the reaction set-up

for

hydrothermal

synthesis. The pressure

generated inside the reactor

can be read from the

pressure

gauge.

Fig.

4.11. Hydrothermal reactor

set-up (ref. 6)

Synthetic

Strategies in Chemistry

4.17

7.2.1

Synthesis of Oxides and

Mixed Oxides

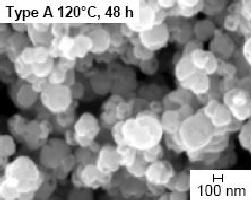

Barium

titanate (BaTiO3)

perovskite is widely used in

electronic industry in

multilayered

ceramic

capacitors due to its high dielectric

constant. Hydrothermal synthesis

route is

promising

due to homogeneity, exact stoichiometry

and spherical morphology of BT

powders

obtained by this synthesis

method at low temperature

(<200 °C). Using

commercially

available titania as Ti precursor

(Degussa P-25) and Barium

hydroxide

precursor

in the Ba: Ti = 1:1 ratio at

a temperature as low as 120 °C for 48

h yielded

BaTiO3 crystals [11]. The

SEM image of BaTiO3 prepared is given in Fig.

4.12.

Fig.

4.12. SEM image of

BaTiO3 crystals (ref.

11).

Alkali

treatment of commercially available

TiO2 (Degussa p-25) in

hydrothermal

conditions

(130 °C) will

result in the formation of

nanotubes of TiO2.

These tubes

obtained

on further hydrothermal treatment at a

high temperature of around 175

°C

will

yield

nanorods of TiO2 [12]. Thus hydrothermal

synthesis provides a route to

play around

different

morphologies of the same

material by simply changing

the temperature.

Hydrothermal

treatment of zinc chloride

hydrazene hydrate at 140 ºC for 12

h

resulted

in the formation of flower

like microrod bundles. The

solution phase is

accelerating

the process of self assembly

through a

dissolution-recrystallization-

decompositiongrowth

process [13]. The chemical

reactions are represented in

the

following

equations. ZnO has variety

of applications in photonics and

optics.

ZnCl2 +

2N2H4

ZnCl2(N2H4)2 ..................(1)

Zn2+ +

2NH3.

H2O

Zn(OH)2+

2NH4+

................(2)

Zn(OH)2

ZnO

+ H2O

......................(3)

4.18

Synthesis

of Materials Based on Solubility

Principle

Fig.

4.13. FE-SEM images of (a)

precursor ZnCl2(N2H4)2 obtained at room

temperature

(b)

ZnO samples obtained at 140 °C and 12 h

(ref. 13).

7.2.2

Synthesis of Noble Metal

Architectures through Hydrothermal

Synthesis

Polymer

protected (PDDA-poly (diallyl

dimethylammonium) chloride)

noble-metal

(including

silver, platinum, palladium, and

gold) nanostructures in the

absence of any

seeds

and surfactants can be synthesized using

hydrothermal method in which

PDDA, an

ordinary

and water-soluble polyelectrolyte, acts

as both a reducing and a

stabilizing

agent.

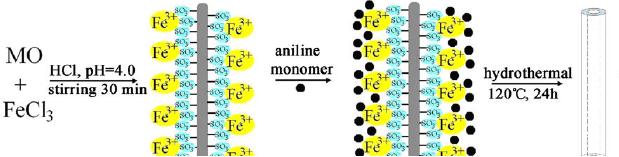

Under

optimal

experimental

conditions,

Ag

nanocubes,

Pt

and

Pd

nanopolyhedrons,

and Au nanoplates are obtained. In

typical synthesis, PDDA

along with

the

respective precursors such as

AgNO3 (170 °C for 16 h),

H2PtCl6

(140 °C

for 40 h),

H2PdCl4

(190 °C

for 40 h) and HAuCl4 (170 °C for 12 h) at

specific pH was used

[14].

Fig.

4.14. Typical SEM and TEM

images of the PDDA-protected

(a) Ag nanocubes (b) Pt

nanopolyhedrons

(c) Pd nanopolyhedrons and (d) Au

nanoplates (ref. 14).

Synthetic

Strategies in Chemistry

4.19

Apart

from metals and metal oxides

hydrothermal synthesis method is

used in the

preparation

of zeolites and mesoporous materials.

This method was also found to

be

effective

in the synthesis of different carbons

such as nanotubes, fullerene and

diamond

[15].

7.2.2

Synthesis of Polymeric Materials

through Hydrothermal

Synthesis

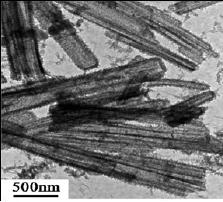

Polyaniline

(PANI) mesostructures have

been synthesized under

hydrothermal

conditions.

The mesostructures show

different forms - fibers,

dendrite fibers,

textured

plates,

featureless plates, and spheres [16]. In

a typical synthesis, a complex

of

FeCl3·6H2O and methyl orange in

hydrochloric acid aqueous solution

(pH = 4.0) was

stirred

and transferred to an autoclave with

aniline monomer and kept at 120 ◦C

for 24 h.

The

material collected was found to be PANI

nanotubes [17]. The

formation mechanism

and

the TEM images of the tubes

formed are given in Scheme 1

and Fig. 4.15. A

fibrillar

complex

of FeCl3 and methyl orange (MO)

acting as reactive selfdegraded templates

in

hydrothermal

conditions was the driving

force for the growth of

nanotubes. MO, which

contains

a hydrophilic group

(SO-3), possesses an anionic

characteristic when

dissolved

in

water. It could dimerize at a

particular concentration to form

higher oligomers.

When

aniline

monomer was added into the

solution, polymerization occurred on

the surface of

MO

where the oxidant

FeCl3 was adsorbed and MO itself

degraded automatically

during

the

polymerization process.

4.20

Synthesis

of Materials Based on Solubility

Principle

Fig.

4.15. TEM of products with pH of

electrolyte (4.0) Synthesis

conditions:

temperature,

120 ◦C;

FeCl3,

1.5 mmol; MO, 0.075 mmol;

aniline, 1.5 mmol (ref.

17).

CONCLUSIONS

The

solubility of a material is having a

major role while designing

the synthetic

strategy

of

any new materials. Solution

phase synthesis always

assisted the self assembly

and

gradual

growth of the crystals of a

variety of materials ranging

from metals, metal

oxides,

chalcogenides,

polymers, zeolites and carbon

materials. Easy tailoring of the

morphology

and

properties can be achieved if solubility concepts

are suitably exploited in

new

material

synthesis. Solution based

chemistry is always important

because ultimate

utility

of

materials is going to be in any

form of life chemistry which

is fully based on aqueous

systems.

Drug delivery materials,

materials in food processing and

preservation,

medicines

and cosmetics are much trivial

cases where the solubility

concepts are

extremely

important. Hence, immense

care should be taken while

designing materials

for

day

today applications through

solution chemistry.

REFERENCES

1.

P. M. Forster, P. M. Thomas and A. K.

Cheetham, Chem.

Mater.,

14 (2002)17.

2.

http://www.elmhurst.edu/~chm/vchembook/174temppres.html

3.

http://research.yale.edu/ysm/article.jsp?articleID=354

4.

Nanostructures and nanomaterials,

Synthesis, Properties and applications,

Cao (Editor)

(2004),

Imperial College press,

London.

5.

en.wikipedia.org/wiki/Nucleation

6.

D. K. Kim Nanoparticle lecture,

2003.

7.

C. M. Janet and R. P. Viswanath, Nanotechnology,

17

(2006) 5271.

Synthetic

Strategies in Chemistry

4.21

8.

Q. Lu, F. Gao, D. Li and S. Komarneni,

A to Z of

Journal of Materials online,

1(2005)

1.

9.

K. Sardar, M. Dan, B. Schwenzer and C. N. R.

Rao, J.

Mater. Chem.,

15 (2005) 2175.

10.

W.-N. Li, L. Zhang, S.

Sithambaram, J. Yuan, X.-F.

Shen, M. Aindow and S. L.

Suib,

J.

Phys. Chem. C.,

111 (2007)

14694-14697.

11.

http://www.isotec-cluster.at/internal/uploads

12.

J.-N. Nian and H. Teng, J. Phys.

Chem. B 110

(2006) 4193.

13.

C. Jiang, W. Zhang, G. Zou, W. Yu and Y.

Qian, J.

Phys. Chem. B. 109

(2005) 136.

14.

H. Chen, Y. Wang, S. Dong, Inorg.

Chem. 46

(2007) 10587.

15.

http://www.sawyerresearch.com/Newsletters/May03newsletter.pdf

16.

L. J. Pan, L. Pu, Y. Shi, T.

Sun, R. Zhang and Y. O. Zheng,

Adv.

Fun. Mater. 16

(2005)

1279.

17. H.

Huang, X. Feng and J.-J. Zhu, Nanotechnology, 19

(2008) 145607.

Table of Contents:

- INTRODUCTION TO SYNTHETIC STRATEGIES IN CHEMISTRY:POROUS MATERIALS

- SYNTHETIC METHODS BASED ON ACTIVATING THE REACTANT:HALOGENATION OF BENZENE

- METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method

- SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE

- SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE

- TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway

- MICROEMULSION TECHNIQUES:Significance of Packing Parameter

- SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS

- NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials

- THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible

- ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS

- NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC

- SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY

- SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice

- CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES

- SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY

- COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES