|

SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE |

| << SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE |

| TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway >> |

Chapter

- 5

SOL-GEL

TECHNIQUES

L.

Hima Kumar

INTRODUCTION

Sol-gel

processing generally refers to the

hydrolysis and condensation of

alkoxide-based

precursors.

It can produce ceramic and

glasses with better purity

and homogeneity than

high

temperature

conventional process. Sol-gel

process can be used to

produce a wide range

of

oxides

in various forms, including

powders, fibers, coatings

and thin films, monoliths

and

porous

membranes. Organic/inorganic hybrids can

also be made, where a gel, usually

silica,

is

impregnated with polymer or

organic dyes with specific

properties. The advantage of

sol-

gel

method is, metal oxides

which are difficult to attain by

conventional methods can be

produced

by using the sol-gel

process. Another benefit is

that the mixing level of

the solution

is

retained in the final

product, often in the

molecular scale.

Sol-gel

processing proved useful in the

manufacturing of stained glass

and for the

preparation

of oxide materials from

sol-gel precursors. Sol-gel derived

products have

numerous

applications. One of the

promising application areas is

for coatings and thin

films

used

in electronics, optical and

electro-optical components and

devices, such as

substrates,

capacitors,

memory devices, infrared

(IR) detectors and wave

guides. Antireflection

coatings

are

also used for automotive and

architectural applications. Submicron

particle size powders

of

single and multicomponent

composition can be made for

structural, electronic, dental,

and

biomedical

applications. Composite powders

can also be used as

agrochemicals or herbicides.

Optical

and refractory fibers are

used for fiber optics

sensors and thermal

insulation,

respectively.

In addition, sol-gel techniques

can be used to infiltrate

fiber performs to

make

composites.

Glass monoliths and coating

and organic/inorganic hybrids are

under

development

for lenses, mirror

substrates, graded index

optics, optical filters,

chemical

sensors,

passive and nonlinear active

waveguides, and lasers.

Membranes for separation

and

filtration

processes also are being

investigated, as well as catalysts.

Biomolecules (such as

proteins,

enzymes, antibodies, etc.) are

incorporated into sol gel

matrices, which can be

used

for

the monitoring of biochemical

processes, environmental testing,

food processing, and

drug

delivery for medicine or

agriculture.

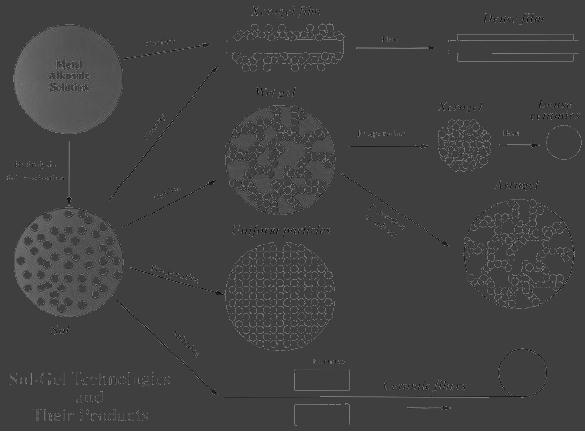

Sol-gel

process, starting with a

metal alkoxide solution and

going through various

processes

and operations until a final

product is obtained, such as a

dense film, an aerogel,

a

ceramic

fiber was shown in Fig.

5.1.

5.2

Sol-Gel

Methods

Fig.

5.1

Schematic

representation

of

the

sol-gel

process

(reproduced

from

http://www.chemat.com/assets/images/Flowchat72.jpg)

DEFINITIONS

A

colloid

is a

suspension in which the dispersed phase

is so small (~1-1000 nm)

that the

gravitational

forces are negligible and

interactions are dominated by

short-range forces,

such

as

van der Waals attraction

and surface charges.

A

sol

is a

colloidal suspension of solid particles

in a liquid.

An

aerosol

is a

colloidal suspension of particles in a

gas.

A

gel

consists

of a three dimensional continuous

network, which encloses a

liquid phase, in a

colloidal

gel, the network is built

from agglomeration of colloidal

particles and is limited

by

the

size of container. In a polymer

gel the particles have a

polymeric sub-structure made by

aggregates

of sub-colloidal particles. Generally,

the sol particles may

interact by van der

Waals

forces or hydrogen bonds. A gel

may also be formed from

linking polymer

chains.

SOL-GEL

SYNTHESIS

Sol-gel

synthesis is a particular approach to the

preparation of glasses and

ceramics at low

temperatures,

which may precede either by

the metallorganic

route,

with metal alkoxides

in

Synthetic

Strategies in Chemistry

5.3

organic

solvents, or by the inorganic

route,

with metal salts (chlorides,

oxychlorides, nitrates,

etc)

in aqueous solution.

GENERAL

MECHANISM

Disregarding

the nature of the precursors,

the sol-gel process can be

characterized by a series

of

distinct steps.

Step

1: Formation of the `sol'

i.e. stable solutions of the

alkoxide or solvated metal

precursor.

Fig.

5.2. Formation of `sol'

(reproduced form ref.

3)

Step

2: Gelation resulting from

the formation of an oxide- or

alcohol-bridged network

(the

gel) by a

polycondensation or polyesterification

reaction that results in a dramatic

increase in

the

viscosity of the solution. If so

desired, the gel may be

cast into a mold during

this step.

Step

3: Aging of the gel, during

which the polycondensation

reactions continue until the

gel

transforms

into a solid mass,

accompanied by contraction of the

gel network and expulsion

of

solvent

from the gel pores. Ostwald

ripening and phase

transformations may

occur

concurrently

with syneresis. The aging

process of gels can exceed 7 days

and is critical to

the

prevention

of cracks in gels that have been

cast.

Step

4: Drying of the gel is,

loss of water, alcohol and

other volatile components,

first as

syneresis

(expulsion of the liquid as

the gel shrinks), then as

evaporation of liquid from

with

in

the pore structure with

associated development of capillary

stress which frequently leads

to

cracking.

This also includes super critical

drying, in which capillary

stress is avoided by

the

use

of supercritical fluids, such as

CO2, in

conditions where there are

no liquid/vapor

densities.

Drying process is complicated

due to fundamental changes in

the structure of the

gel.

The drying process has

itself been broken into four

distinct steps:

5.4

Sol-Gel

Methods

(i)

Constant rate period, (ii)

the critical point, (iii)

the first falling rate

period, and (iv)

the

second

falling rate period. If

isolated by thermal evaporation,

the resulting monolith is

termed

a

xerogel. If the

solvent is extracted under

supercritical or near supercritical

conditions, the

product

is an aerogel.

Fig.

5.3. Formation of gel

(reproduced form ref.

3)

Fig.

5.4. Aging of gel

(reproduced form ref.

3)

Synthetic

Strategies in Chemistry

5.5

Step

5: Dehydration, during which

surface-bound M-OH groups are removed,

thereby

stabilizing

the gel against rehydration.

This is normally achieved by

calcining the monolith

at

temperatures

up to 800 °C.

Step

6: Densification and decomposition of

the gels at high temperatures (T

>

800 °C). The

pores

of the gel network are

collapsed, and remaining

organic species are volatilized.

This

step

is normally reserved for the

preparation of dense ceramics or

glasses.

Fig.

5.5. Densification (reproduced

form ref. 3)

INORGANIC

ROUTE

The

growth of metal-oxo polymers in a

solvent inorganic polymerization

reactions through

hydrolysis

and condensation of metal

alkoxides M(OR)Z,

where M = Si, Ti, Zr, Al, Sn,

Ce,

OR

is an alkoxy group and Z is

the valence or the oxidation

state of the metal, occur in

two

steps

First

step: hydrolysis, Metal cations,

Mz+,

are formed by dissolving

metal salts in water,

are

solvated

by water molecules as

follows:

Mz+ + hH2O

[M(OH2)h]z+

---------------------------------------------------------(1)

where

h

is

the coordination number of

the cation. The

electron-transfer weakens the

O-H

interactions

of bound water, and

depending on the pH of the

solution, various degrees

of

hydrolysis

(deprotonation) can be

induced:

[M(OH2)]z+

[M-OH](z-1)+

+ H+

[M=O](z-2)+

+ 2H+ ------------------------------(2)

In

general, hydrolysis reaction is

facilitated by increase in the charge

density on the metal,

the

number

of metal ions bridged by a

hydroxo or oxo ligand, and

the number of

hydrogens

contained

in the ligand. It also

affected by the pH. The

typical effects of charge and pH

are

shown

in Fig. 5.6, where three

domains corresponding to aquo,

hrdroxy and oxo ions

are

5.6

Sol-Gel

Methods

defined.

Acidic conditions force the

equilibria (Eq. 2) to the

left and favor the

formation of

hydroxo

ligands, whereas basic conditions will

force the equilibria to the

right and favor

oxo

ligands.

The charge on the metal,

however, also plays a

significant role in the

above

equilibria

with respect to pH, given

that highly positive charges

on the metals tend to

substantially

weaken the O-H bonds

and favor the formation of

oxo ligands.

Fig.

5.6. Relationship between charge, pH

and hydrolysis equilibrium of

cations (reproduced

form

ref. 1)

Second

step: polycondensation process leading to

the formation of branched

oligomers and

polymers

with a metal-oxo based

skeleton and reactive

residual hydroxo and alkoxy

groups

M-OH

+ XO-M

M-O-M

+ XOH

--------------------------------------------------------(3)

This

condensation step occurs by

either of the following

ways

1.

Olation, is

a condensation in which a hydroxyl

bridge is formed.

2.

Oxolation,

is condensation in which a oxo

(-O-) bridge is

formed.

Synthetic

Strategies in Chemistry

5.7

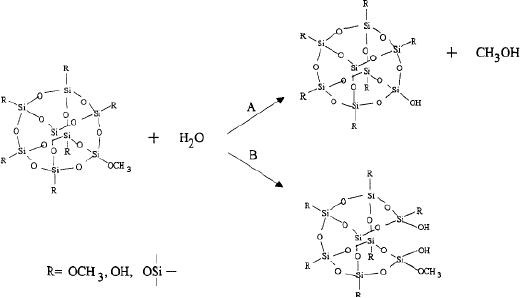

Chemical

Reactivity of Metal

Alkoxides

The

chemical reactivity of metal

alkoxides can be examined

under acidic and

basic

conditions,

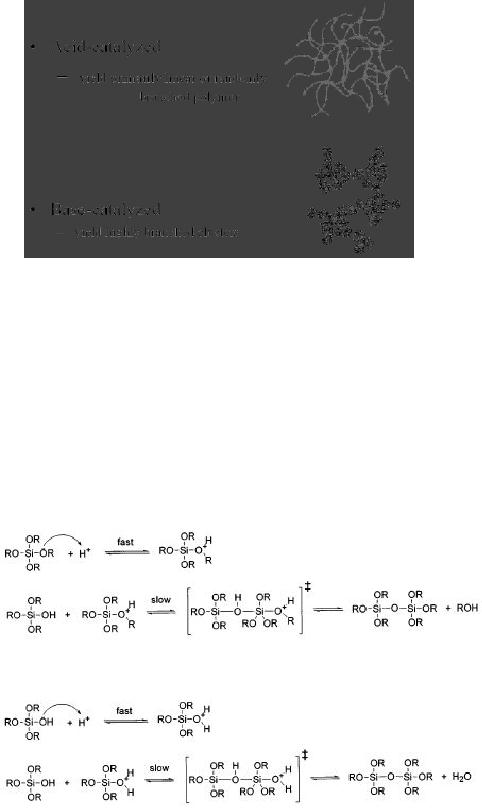

as shown in Fig. 5.7.

Fig.

5.7. Polymer structures formed in

acid or basic environments (reproduced

from ref. 1)

As

with initial hydrolysis,

condensation reactions may be

either acid catalyzed or

base

catalyzed

and either cases the

reaction proceeds via a

rapid formation of charged

intermediate

by

a reaction with a proton or

hydroxide ion, followed by

slow attack of second

neutral

silicon

species.

Under

acidic conditions (e.g. with

mineral acids), hydrolysis is faster

than condensation, as

shown

in the following

reaction:

or

5.8

Sol-Gel

Methods

For

Si(OR)4-n(OH)n, under

acidic conditions (pH <

4), the rate of hydrolysis

will always be

faster

than the rate of

condensation due to the

ability of -OR groups to

better stabilize the

transition

states. Condensation involves

the attack of silicon atoms

carrying protonated

silanol

species on neutral Si-OH

nucleophiles. A bushy network of

weakly branched

polymers

is obtained under acidic

conditions.

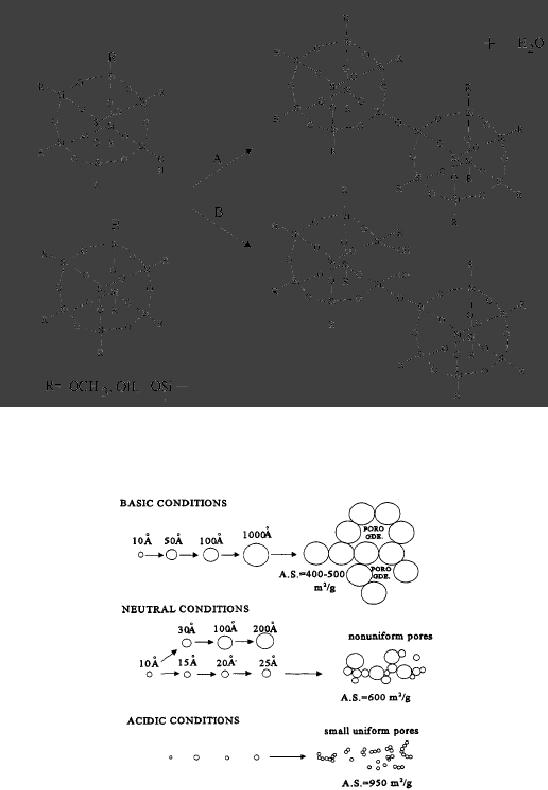

followed

by

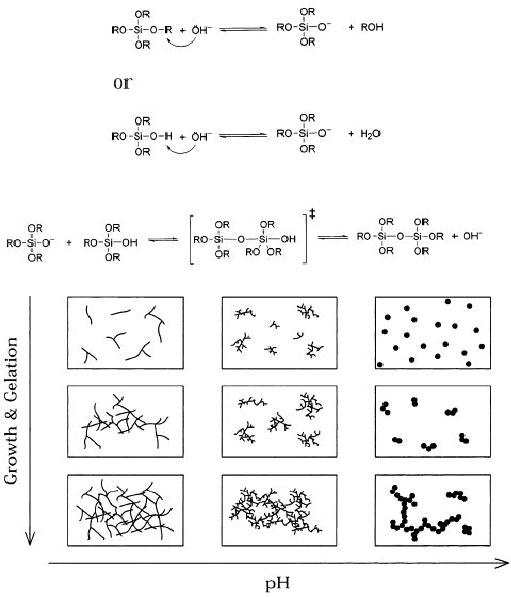

Fig.

5.8. Effect of pH on particle

morphology in sol-gel reactions

(reproduced from ref.

6)

The

result of basic catalysis is an

aggregation (monomer cluster)

that leads to more compact

highly

branched silica networks

that are not interpenetrable

before drying and thus

behave as

Synthetic

Strategies in Chemistry

5.9

discrete

species. The differences

between acid and base

catalyzed reactions and

the

consequences

for particle morphology are

conceptually represented in Fig.

5.8.

Gelation

Gelation

is freezing in a particular structure

(i.e. may be considered as a

rapid solidification

process).

Gelation occurs when links

form between silica sol

particles produced by

hydrolysis

and

condensation, to such an extent

that a giant spanning

cluster reaches across

the

containing

vessel. In other words, as the

sol particles grow and

collide, lead to the

condensation

and then forming

macroparticles. The sol

becomes a gel when it can

support a

stress

elastically. This is typically

defined as the gelation

point or gelation time.

All

subsequent

stages of processing depend on the

initial structure of the wet

gel formed in the

reaction

bath during gelation. Under

acid catalysis polymeric gels

are gradually formed,

as

depicted

in Fig. 5.8. Under basic

conditions and/or with

higher additions of water,

more

highly

branched clusters are formed,

which behave as discrete

species. If the total

concentration

of alkoxysilane is low, e.g., <

~0.3 M, gelation leads to formation of

colloidal

silica

(Stoeber process).

Aging

When

a gel is maintained in its

pore liquid, its structure

and properties continue to

change

long

after the gel point.

This process is called

aging. During aging, four

processes can occur,

singly

or simultaneously, including

polycondensation, syneresis, coarsening,

and phase

transformation.

Polycondensation

reactions occur continuously,

within the gel network as

long as

neighboring

silanols are close enough to react.

This increases the

connectivity of the

network

and

its fractal dimension.

Usually in alkoxide-based gels,

the chemical hydrolysis

reaction is

rapid,

especially, when the sol is

acid catalyzed, and is

completed in the early

stages of sol

preparation.

Since the chemical reaction

is faster at higher temperatures, aging

can be

accelerated

by hydrothermal treatment, which

increases the rate of the

condensation reaction.

Syneresis

is the spontaneous shrinkage of the

gel and resulting expulsion

of liquid from

the

pores. Syneresis in alcoholic gel systems

is generally attributed to formation of

new

bonds

through condensation reactions,

which increases the bridging

bonds and causes

contraction

of the gel network. In

aqueous gel systems or

colloidal gels, the

structure is

controlled

by the balance between

electrostatic repulsion and

attractive van der Waals

forces.

Therefore,

the extent of shrinkage is

controlled by additions of

electrolyte.

5.10

Sol-Gel

Methods

Coarsening

or Ostwald ripening is the

irreversible decrease in surface area

through

dissolution

and reprecipitation processes.

Structural changes attributed

primarily to surface

energy

effects. It is well known

that surfaces exhibiting

positive radii of curvature

dissolve

more

readily than surfaces

exhibiting negative radii of

curvature. If a gel is immersed in

a

liquid

in which it is soluble, dissolved

material will tend to precipitate

into regions of

negative

curvature. Therefore, as the

dissolution rate increases, dissolution

redeposition

results

in neck formation, causing

the gel structure to become

fibrillar and the pore

formation.

Further,

when dissolution is extensive,

the gel network would

break down and ripen to

form a

colloidal

sol.

During

aging, there are changes in

most physical properties of the

gel. Time,

temperature,

solvent

and pH conditions affect the

aging process and lead to

structural modifications.

Heating

the gel in water at 80-100

°C

can strengthen the weak

gel structure and

generally

brings

about reinforcement, but

does not modify the

pore structure. The pH of

the wash water

during

the washing of pore liquor

out of gel is critical in

the case of gels made from

acid-

catalyzed

silicate precursors. The final

properties of such gels depend on

both the pH at

which

the gel was formed

and the pH at which it was

aged before drying.

Drying

Drying

is nothing but removing of

the solvent phase. The

method is influenced by

the

intended

use of the dried material.

If powdered ceramics are desired, no

special care need be

exercised

to prevent fragmentation; if monoliths

from colloidal gels are desired,

the drying

procedures

are largely determined by

the need to minimize internal

stresses associated

with

the

volume changes on drying and

the capillary forces in the

gel pores.

There

are three stages of

drying:

During

the first stage of drying,

the volume change of the gel

equals the volume of

·

evaporated

liquid. The gel network is

still flexible and can

rearrange to accommodate the

decreasing

volume. The compliant gel

network is deformed by the

large capillary

forces,

which

causes shrinkage of the

object. All pores are filled

with solvent and no

liquid-air

interfaces

are present. In classical large-pore systems,

this first stage of drying

is called "the

constant

rate period" because the

evaporation rate per unit

area of the drying surface

is

independent

of time. First stage of

drying ends when shrinkage

stops.

Second

stage of drying begins when

the "critical point" is

reached (Fig .8). The

packing

·

density

of the solid phase increases

with increasing the strength

of the network, and

resists

further

shrinkage. This stage is

called critical point. As

drying proceeds, the gel

network

Synthetic

Strategies in Chemistry

5.11

becomes

more restricted and the

removal of liquid leads to the

formation of such

interfaces

and

the development of capillary

stresses. The liquid flows

to the surface where

evaporation

takes

place. The flow is driven by

the gradient in capillary

stress. Because the rate

of

evaporation

decreases in second stage,

classically this is termed

"the first falling rate

period'.

Fig.

5.9. Schematic representation of

gel surface at the end of

first stage (critical

point)

(reproduced from ref.

4)

When

the pores have substantially

emptied, surface films along

the pores cannot be

·

sustained.

This is third stage of

drying, which is also called

as "second falling rate

period".

The

remaining liquid can escape

only by evaporation from

within the pores and

diffusion of

vapor

to the surface. During this

stage, there are no further

dimensional changes but just

a

5.12

Sol-Gel

Methods

slow

progressive loss of weight

until equilibrium is reached, determined

by the ambient

temperature

and partial pressure of

water.

The

capillary pressure, P, developed in a

cylindrical capillary of radius r,

partially filled

·

with

a liquid of wetting angle

α,

can be expressed by:

2γ

cos

α

ĆP =

r

where

γ

is

the surface tension. When

evaporation leads to the formation of

menisci, the

different

radii of the pores cause

unequal capillary pressures to generate

differential stresses.

If

the stress difference

locally exceeds the strength

of the gel network, a crack

will result

(drying

failure). When the gel

has had insufficient aging

and strength, does not

possess the

dimensional

stability to withstand the

increasing compressive stress and leads

to cracking in

the

first stage. Most failure of

drying occurs during the

early part of second stage,

the point at

which

the gel stops shrinking.

This is the point at which

the meniscus falls below

the surface.

Generally,

fractures associated with excessive

capillary forces can be eliminated

or

reduced

by one or more of the

following proceedings:

strengthening

the gel by

reinforcement

·

enlarging

the pores

·

reducing

the surface tension of the

liquid with surfactants

·

making

the interior surfaces

hydrophobic

·

evacuating

the solvent by

freeze-drying

·

Operating

under hypercritical

conditions.

·

Xerogel

and Aerogel Formation

As

a gel is evaporated to dryness either by

thermal evaporation or supercritical

solvent

extraction,

the gel structure changes in

some cases substantially.

During thermal drying

or

room-temperature

evaporation, capillary forces induce

stresses on the gel that

increases the

coordination

numbers of the particles and

induces collapse of the

network. The increase in

particle

coordination numbers results in the

formation of additional linkages

that strengthen

the

structure against further

collapse and eventually leads to

the formation of a rigid

pore

structure.

The structure of the

resulting xerogel can

therefore be considered a

collapsed,

highly

distorted form of the

original gel network.

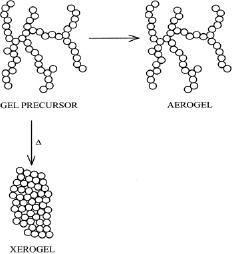

The

supercritical extraction of solvent

from a gel does not

induce capillary stresses

due to

the

lack of solvent-vapor interfaces. As a

result, the compressive forces exerted on

the gel

Synthetic

Strategies in Chemistry

5.13

network

are significantly diminished

relative to those created during

formation of a xerogel.

Aerogels

consequently retain a stronger

resemblance to their original gel

network structure

compared

to xerogels (Fig.

5.10).

Fig.

5.10. Structural relationship

between a sol-gel precursor, a

xerogel, and an

aerogel

(reproduced

from ref. 6)

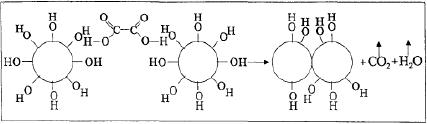

Densification

Densification

is the last treatment

process of gels during which

the dried gel is heated

to

convert

into a dense ceramic. The

sintering of gels, where the

pore network is collapsed

and

organic

species are volatilized, is a

critical factor in determining

the size and morphology

of

the

sol-gel product. For silica

gels, the following

reactions occur during the

densification:

desorption

of physically adsorbed solvent and

water from the walls of

micropores (100-

·

200

°C)

decomposition

of residual organic groups

into CO2 + H2O

(300- 500 °C)

·

collapse

of small pores (400-500

°C)

·

collapse

of larger pores (700-900

°C)

·

continued

polycondensation (100-700

°C)

·

If

powdered ceramics are

desired, no need to take care to

prevent fragmentation.

Attention

must,

however, be directed to the

removal of organics to avoid

undesirable bloating,

foaming

or

blackening. Where as, for

monoliths preparation, special

care must be taken to

ensure

complete

removal of water, organic

groups or decomposition products,

prior to micropore

collapse

to avoid the development of

stresses leading to fragmentation

for the production of

large

monoliths of SiO2.

5.14

Sol-Gel

Methods

Sintering

and densification phenomena also

take place, via typical

sintering mechanisms

such

as

evaporation condensation, surface

diffusion, and grain

boundary and bulk diffusion.

The

small

particle size of the powders

lead to high reactivities

and enhanced sintering

and/or

coarsening

rates (the principal process

involved in densification is often

viscous sintering).

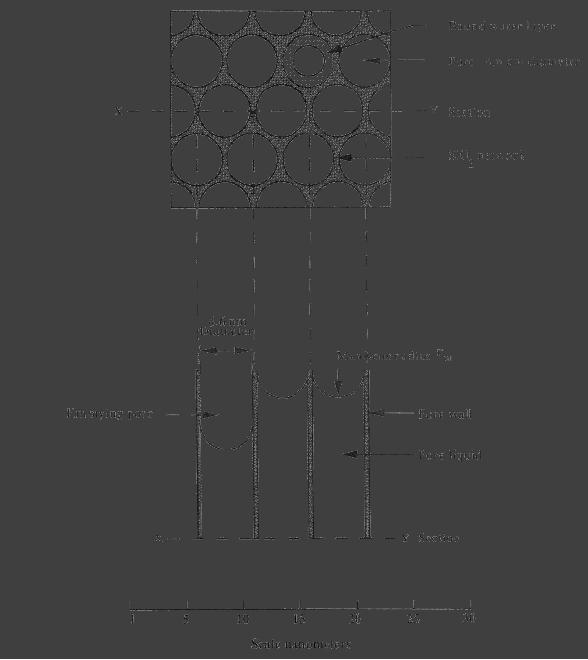

As

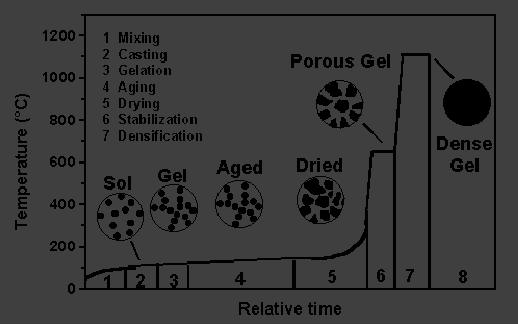

illustrated in Fig. 5.11,

densification of a gel network

occurs between 1000 and

1700 °C

depending

upon the radii of the pores

and the surface area. Fig.

5.11, describes the

overall

development

of a sol-gel process for

glass in relative time and

temperature scales.

This

schematic

representation summarizes from

establishment of a sol condition to

formation of a

dense

material.

Fig.

5.11. Time vs. Temperature

dependence in a sol-gel process

(reproduced

from ref. 4)

APPLICATIONS

Monoliths

The

physical properties of gel-derived

glasses are usually closely

similar to those of

glasses

obtained from the melt.

Gel-derived powders are used

as batch ingredients

for

glass

melting primarily because of

the high degree of chemical

homogeneity they

offer.

This

leads to shorter melting times

and lower melting

temperature as well as

compositional

uniformity. The key to glass

formation is the development of

an

appropriate

heat treatment schedule to remove the

residual organic groups and

achieve

pore

collapse without inducing

crystallization in the sample. The most

attractive feature is

the

development of novel glass

compositions: CaO-SiO2 or Na2O-ZrO2-SiO2 with high

ZrO2 content, which is

impossible to obtain from

the melt, because the

cooling rate must

Synthetic

Strategies in Chemistry

5.15

be

high to avoid detectable

crystallization. Monoliths are

defined as bulk gels cast

to

shape

and processed without

cracking. Monolithic gels are

potentially interesting

because

complex

shapes may be formed at room

temperature and consolidated at

rather low

temperatures

with out melting. The

principle applications of monoliths

are optical ones:

fiber

optic preforms, lenses and

other near-net-shape optical components,

graded

refractive

index glasses and

transparent foams (Aerogels) used as

Cherenkov detectors

and

as super insulation.

Fibers

Fibers

can be drawn directly from

polymer sols by controlling

the viscosity of acid

catalyzed

alkoxide

gels. A key to prevent premature

gelation is to maintain water at a

lower level. High

viscosity

stabilizes the fibers

against spheroidization during

the drawing operation.

Both

silica

and titania fibers have been

obtained at near room

temperature, but without

sintering,

they

remain porous and contain

some unreacted alkoxide. The

porosity decreases

with

increasing

temperature. Sol-gel method

using metal alkoxide as precursor

has been applied to

the

preparation of oxide glass

fibers other than

SiO2.

Fibers produced by sol-gel

processing

are

an interesting application for

the manufacture of optical

waveguides (A device

that

constrains

or guides the propagation of

electromagnetic radiation along a

path defined by the

physical

construction of the guide is

called waveguide). The

dispersion-casting technique

produces

silica fibers with optical

loses of about 3.5

dB/km.

Thin

films and coatings

Thin

films and coatings were

the first commercial

application of sol-gel processing

technology.

Films are applied either by

dip coating or spin coating

techniques, using

polymeric

alkoxide sols. By controlling the

precursor chemistry and

deposition conditions,

pore

size, porosity, surface area, and

refractive index of the

films can be controlled.

Large

substrates

may be accommodated and it is possible to

uniformly coat both sides of

planar and

axially

symmetric substrates such as

pipes, tubes, rods and

fibers.

Generally,

ceramics are more resistant

than metals to oxidation, corrosion,

erosion and

wear.

Moreover, they can have

good thermal and electrical

properties that make

them

particularly

interesting as coating materials.

Ceramic coatings are usually

deposited on metals

for

improving their performances in

high temperature aggressive environments.

Some

important

applications, include improving

resistance against gas,

solid, condensed, and

molten-phase

corrosion, to localized overheating

and melting; decreasing fretting

and wear;

decreasing

heat losses and/or reflecting

radiations in high temperature

systems.

5.16

Sol-Gel

Methods

A

major development was the

formation of multiple transparent

layers that produce a

gradual

change

in refractive index from the

air interface to that of the

substrate. Antireflection

coatings

are also a vast application of

the sol-gel technique, for

example, in store front

windows,

to allow light transmission

but reduced glare. Such coatings

are also used in

solar

cells

and laser optics. A head up display is a

unique application of these

coatings: by

controlling

the reflectance to transmission

ratio, the speed of the

automobile can be

displayed

at

eye level on the windshield,

without distorting the field

of view. The driver no

longer

needs

to shift his eyes to the

instrument panel.

Electrochromic

devices

Active

electronic thin films

include high temperature superconductors,

conductive indium tin

oxide

(ITO) and vanadium

pentoxide, and ferro

electric barium and lead

titanates,

electrochromic

tungsten oxide, and titania

films used as phtotoanodes.

Solid state

electrochromic

(EC) devices for smart

windows, large area displays

and automotive

rearview

mirrors

are of considerable technological

and commercial

interest.

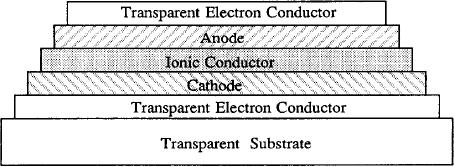

Fig.

5.12. Schematics of an EC window device

deposited on one substrate.

The

electrochromic

layer is anode, cathode or both

(reproduced from ref

.7).

Controlled

modulation of solar radiation

through smart windows has a

large potential in

buildings

for energy savings and in

automobiles to increase occupant comfort

while reducing

air

conditioning requirements. Typically

these devices consist of multiple

layer stacks that

are

sequentially

vacuum deposited or are

laminate constructions. Sol-gel

processing offers

advantage

in depositing films containing

multiple cations and

controlling the

microstructure.

These

parameters can influence the

kinetics, durability, coloring

efficiency and charge

storage

in the electrochromic films

(electrodes). A typical structure of a

solid state

electrochromic

window is shown in Fig.

5.12.

Other

applications of sol-gel techniques

include

Synthesis

of carbides sulphides and

nitrides

Synthetic

Strategies in Chemistry

5.17

Synthesis

of nanocomposites

Synthesis

of powders, grains and

spheres

Catalysis

( Mesoporous materials)

Preparing

solid electrolytes

Absorbing

coatings

Filters

for lighting and optical

purposes

Semiconducting

coatings

Protective

layers (both chemical and

thermal)

Scratch

resistant coating

Embedding

organic molecules (hybrid

organic-inorganic materials)

Flammable

gas sensors

Porous

gels and membranes

REFERENCES

1.

C. J. Brinker, and G. W. Scherer,

Sol-Gel Science: The Physics and

Chemistry of Sol-Gel

Processing,

Academic Press Inc., New

York, 1989.

2.

J. D. Wright and N.A.J.M

Sommerdijk, Sol-gel materials

chemistry and applications,

vol.4,

Taylor

& Francis Books Ltd.,

London, 2001.

3.

R. D. Gonzalez, T. Lopez and R.

Gomez, Sol-Gel preparation of

supported metal catalysts.

Catalysis

Today, 35 (1997) 293.

4.

L. C. Klein, (Ed.), Sol-Gel

Optics: Processing and Applications,

Kluwer Academic

Publishers,

Boston, 1993.

5.

L.L. Hench and J.K. West,

The sol-gel process. Chem.

Rev., 90 (1990) 33.

6.

B. L. Cushing, V.L. Kolesnichenko and

C.J. O'Connor, Recent Advances in

the Liquid-

Phase

Syntheses of Inorganic Nanoparticles.

Chem. Rev., 104 (2004)

3893.

7.

A. Agrawal, J.P. Cronin and

R. Zhang, Review of solid

state electrochromic

coatings

produced

using sol-gel techniques.

Solar Energy Materials and

Solar Cells, 31 (1993)

9.

Table of Contents:

- INTRODUCTION TO SYNTHETIC STRATEGIES IN CHEMISTRY:POROUS MATERIALS

- SYNTHETIC METHODS BASED ON ACTIVATING THE REACTANT:HALOGENATION OF BENZENE

- METHODS BASED ON ACTIVATING THE REACTING SUBSTANCE:Experimental method

- SYNTHESIS OF MATERIALS BASED ON SOLUBILITY PRINCIPLE

- SOL-GEL TECHNIQUES:DEFINITIONS, GENERAL MECHANISM, INORGANIC ROUTE

- TEMPLATE BASED SYNTHESISSynthesis, Mechanism and Pathway

- MICROEMULSION TECHNIQUES:Significance of Packing Parameter

- SYNTHESIS BY SOLID STATE DECOMPOSITION:DECOMPOSITION METHODS

- NEWER SYNTHETIC STRATERGIES FOR NANOMATERIALS:Nanostructured Materials

- THE ROLE OF SYNTHESIS IN MATERIALS TECHNOLOGY:The Holy Bible

- ELECTROCHEMICAL SYNTHESIS:FEATURES OF ELECTROCHEMICAL SYNTHESIS

- NEWER REACTIONS AND PROCEDURES: CATALYTIC AND NONCATALYTIC

- SYNTHETIC STRATEGIES - FROM LABORATORY TO INDUSTRY

- SYNTHESIS OF CHEMICALS FROM CARBON DIOXIDE:Carbon dioxide - Dry Ice

- CARBOHYDRATES TO CHEMICALS:MONOSACCHARIDES

- SOME CONCEPTUAL DEVELOPMENTS IN SYNTHESIS IN CHEMISTRY

- COMPUTATIONAL BASICS UNDERLYING SYNTHETIC STRATEGIES