|

Production

and Operations Management

MGT613

VU

Lesson

19

Facilities

layout corresponds to configuration of

departments, sections, work

centers, equipment

with

focus

being on movement of goods or services or

works. A traveler making use

of the railway platform,

or

bus station or airport would

be a good example of work

being moved through a

facility. Often poor

design

of productive system can

result in poor design of the facilities

layout. After 9, 11, most of

the

airports

in the western world have shown that

they are poorly designed to

handle air traffic

and

passengers

end up paying a heavy price in the

form of long waiting hours and even

people visit airports

to

see of their family or

friend travelers end up reaching the

lobby area. The reason

being no attention

was

paid at the time of design or

construction to separate boarding

lounge form the ticketing counter

or

lounge.

Such short comings plague organizations

and it's the task of the operations

manager to ensure

that

product as well as service layouts

match organizations short as well as

long term plans.

Basic

Layout Types

The

common Basic Layout Types

are

1.

Product/Service layout. A layout that

uses standardized processing operations to

achieve

smooth,

rapid, high-volume

flow

2.

Process layout. A Layout

that can handle varied

processing requirements

3.

Fixed Position layout. A

Layout in which the product or

project remains stationary,

and

workers,

materials, and equipment are moved as

needed

4.

Hybrid/Combination. A Layout that

makes use of the combination of Product,

Process or Fixed

Position

Layout.

PRODUCT

LAYOUT CHARACTERISTICS

1.

Product layouts are used to achieve a

smooth and rapid flow of

large volumes of goods

and

customers

through a system.

2.

The work is divided into a

series of standardized tasks, permitting

specialization of both

labor

and

equipment.

3.

The large volumes handled by

these systems make it

pertinent and necessary to invest

in

equipment

and job design.

4.

Layouts should be arranged to make the

best use of technological

processing abilities to

fulfill

the

requirements of both product and

services.

5.

In manufacturing environments the lines

are referred to as production

lines or assembly

lines,

depending

on the type of activity

involved.

6.

In services side, the word line

may or may not be used

like Healthcare/Hospital Services

line,

Carwash

(absence of word line here) or

Cafeteria Line.

7.

Without standardization, many of the

benefits of the repetitive processing

are lost.

8.

Product Layouts achieve a high degree of

labor and equipment utilization,

which tends to offset

their

high equipment costs.

9.

Operations are so closely tied up

that a mechanical failure or high

absenteeism (rains)

would

increase

vulnerability of the Systems.

10.

We can prevent breakdowns if we

religiously follow preventive maintenance

schedules,

inspection

and replacement of worn

parts.

Advantages

of Product Layout

1.

High rate of output.

2.

Low unit cost.

3.

Labor specialization.

4.

Low material handling

cost.

5.

High utilization of labor and

equipment.

6.

Established routing and

scheduling.

7.

Routing accounting and purchasing.

81

Production

and Operations Management

MGT613

VU

Disadvantages

of Product Layout

1.

Creates dull, repetitive

jobs.

2.

Poorly skilled workers may

not maintain equipment or

quality of output of service.

3.

Fairly inflexible to changes in

volume.

4.

Highly susceptible to shutdowns.

5.

Needs preventive maintenance.

6.

Individual incentive plans are

impractical.

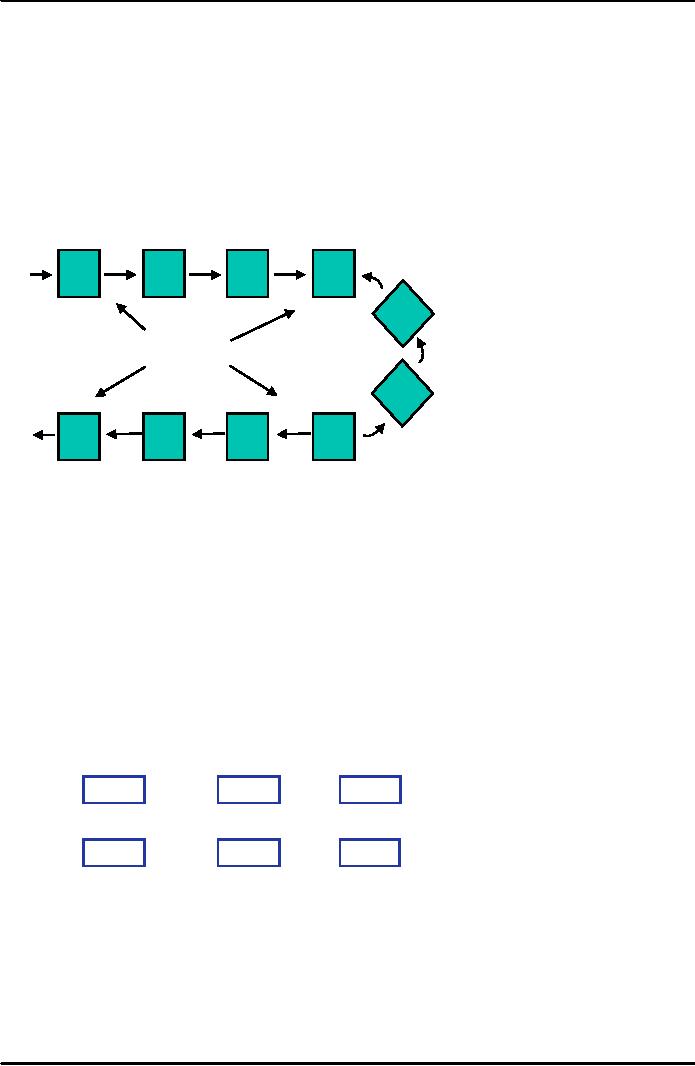

A

U-Shaped Production

Line

1

2

3

4

I

5

Worker

6

Ou

10

9

8

7

A

U-Shaped Production

Line

Straight

Line designs are often

not practical because of

space constraints. U shape Production

Line is

more

compact, and requires often half the

length of a Straight Production

Line.

U

shaped Layouts are a must

for teamwork where communication is

necessary. U shaped Layouts

allow

flexibility

in work assignments as workers

can handle adjacent stations as well as

stations on opposite

ends.

Sometimes U shaped production

line interferes with the

cross travel/movement of workers,

mobile

equipment.

Highly automated processes do not

require teamwork or communication, noise

or

contamination

factors then U shaped Production

Lines are not

required.

Process

Layout

Process

Layout

(Functional)

Dept.

Dept.

Dept.

Dept.

Dept.

Dept.

Used

for intermittent

processing

Job

Shop or Batch

82

Production

and Operations Management

MGT613

VU

Product

Layout

Product

Layout

(Sequential)

Work

Work

Work

Station

Station

Station

Used

for Repetitive

Processing

Repetitive

or Continuous

Advantages

of Process Layouts

1.

Can

handle a variety of processing

requirements.

2.

Not

particularly vulnerable to equipment

failures.

3.

Equipment

used is less costly.

4.

Possible

to use individual incentive

plans.

Disadvantages

of Process Layouts

1.

In-process inventory costs can be

high.

2.

Challenging routing and

scheduling.

3.

Equipment utilization rates

are low.

4.

Material handling slow and

inefficient.

5.

Complexities often reduce

span of supervision.

83

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMERíS AND PRODUCERíS RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model