|

Project

Management MGMT627

VU

LESSON

28

NETWORK

SCHEDULING TECHNIQUES

BROAD

CONTENTS

Introduction

Benefits

and Advantages of Scheduling

Historical

Evolution of Network

Scheduling

Network

Fundamentals and Terminology

Pert/CPM

and their Difference

Graphical

Evaluation and Review Techniques

(GERT)

Dependencies

or Interrelationship

Slack

Time

28.1

Introduction:

In

today's highly competitive

environment, management is continually

seeking new and better

control

techniques to cope with the complexities,

masses of data, and tight deadlines

that are

characteristic

of many industries.

In

addition, management is seeking better

methods for presenting technical and

cost data to

customers.

Since

World War II, scheduling techniques have

taken on paramount importance. The

most

common

of these techniques are shown

below:

·

Gantt

or bar charts

·

Milestone

charts

·

Line

of balance

·

Networks

o

Program

Evaluation and Review Technique

(PERT)

o

Arrow

Diagram Method (ADM) [Sometimes called

the Critical Path Method

(CPM)]

o

Precedence

Diagram Method (PDM)

o

Graphical

Evaluation and Review Technique

(GERT)

28.2

Benefits

and Advantages of Scheduling:

The

Program

Evaluation and Review Technique

(PERT) perhaps

is the best known of all

the

relatively

new techniques. PERT has several

distinguishing characteristics:

·

It

forms the basis for all

planning and predicting and provides

management with the

ability

to

plan.

·

It

enables management for best

possible use of resources to achieve a

given goal within

time

and cost limitations.

·

It

provides visibility and enables

management to control ''one-of-a-kind"

programs as

opposed

to repetitive situations.

·

It

helps management to handle uncertainties

involved by answering the following

questions

that

provides management with a

means for evaluating

alternatives:

a)

How time delays in certain

elements influence program

completion?

b)

Where slack exists between elements?

c)

What elements are crucial to

meet the completion

date?

197

Project

Management MGMT627

VU

·

It

provides a basis for

obtaining the necessary facts

for decision making.

·

It

utilizes a time network analysis as the

basic method to determine manpower,

material,

and

capital requirements as well as providing

a means for checking

progress.

·

It

provides the basic structure for

reporting information.

·

It

reveals interdependencies of activities.

·

It

facilitates "what if"

exercises.

·

It

identifies the longest path or

critical paths.

·

It

allows us to perform scheduling

risk analysis.

The

above-mentioned benefits apply to

all network scheduling techniques,

not just PERT.

28.3

Historical

Evolution of Networks:

Before

going further with the

details, let us have an insight

into the historical evolution

of

networks.

PERT was originally

developed in 1958 and 1959

to meet the needs of the "age

of

massive

engineering" where the techniques of Taylor

and Gantt were inapplicable.

The Special

Projects

Office of the U.S. Navy,

concerned with performance trends on

large military

development

programs, introduced PERT on its Polaris

Weapon System in 1958, after

the

technique

had been developed with the

aid of the management consulting

firm of Booz, Allen,

and

Hamilton. Since that time,

PERT has spread rapidly

throughout almost all industries.

At

about

the same time the Navy was

developing PERT, the DuPont

Company initiated a

similar

technique

known as the Critical

Path Method (CPM),

which also has spread

widely, and is

particularly

concentrated in the construction and process

industries.

The

basic requirements of PERT/time as established by the

Navy, in the early 1960s, were as

follows:

·

All

of the individual tasks to complete a

given program must be

visualized in a manner

clear

enough to be put down in a

network, which comprises

events and activities; that

is,

follow

the work breakdown structure.

·

Events

and activities must be sequenced on the

network under a highly

logical set of ground

rules

that allow the determination of

important critical and sub-critical

paths. Networks can

have

up to one hundred or more events, but

not less than ten or

twenty.

·

Time

estimates must be made for

each activity of the network on a

three-way basis.

Optimistic,

most likely, and pessimistic elapsed-time

figures are estimated by the

person(s)

most

familiar with the activity

involved.

·

Critical

path and slack times are computed.

The critical path is that

sequence of activities

and

events whose accomplishment will

require the greatest expected

time.

28.3.1

Advantages of PERT:

1.

Firstly,

a major advantage of PERT is the kind of

planning required to a

major

network.

Network development and

critical path analysis

reveal

interdependencies

and problem areas that are

neither obvious nor well

defined

by

other planning methods. The

technique therefore determines where

the

greatest

effort should be made for a

project to stay on

schedule.

2.

By

using PERT one can determine the

probability of meeting

specified

deadlines

by development of alternative plans. If the

decision maker is

statistically

sophisticated, he can examine the

standard deviations and the

probability

of accomplishment data. If there exists a minimum of

uncertainty,

one

may use the single-time approach, of

course, while retaining the

advantage

of

network analysis.

3.

A

third advantage is the ability to

evaluate the effect of changes in the

program.

For

example, PERT can evaluate the

effect of a contemplated shift of

resources

198

Project

Management MGMT627

VU

from

the less critical activities to the

activities identified as

probable

bottlenecks.

Other resources and performance

trade-offs may also be

evaluated.

4.

PERT

can also evaluate the effect of a

deviation in the actual time required

for

an

activity from what had been

predicted.

5.

Lastly,

PERT allows a large amount of

sophisticated data to be presented in

a

well-organized

diagram from which both

contractor and customer can

make

joint

decisions.

Unfortunately,

PERT is not without its

disadvantages. The complexity of PERT

adds to

the

implementation problems. There exist more

data requirements for a PERT

-

organized

MCCS reporting system than

for most others. PERT,

therefore, becomes an

item

that is expensive to maintain and is

utilized most often on

large, complex

programs.

Many

companies have taken a hard

look at the usefulness of PERT on

small projects in

recent

years. The literature contains

many diversified approaches

toward applying

PERT

to other than large and

complex programs. The result

has been the PERT/LOB

procedures,

which, when applied

properly, can do the following

job:

·

Cut

project costs and reduce

time scale

·

Coordinate

and expedite planning

·

Eliminate

idle time

·

Provide

better scheduling and control of subcontractor

activities

·

Develop

better troubleshooting

procedures

·

Cut

the time required for

routine decisions, but allow more

time for decision

making

Note

that even with these

advantages, many companies

should ask themselves

whether

they

actually need PERT.

Incorporation of PERT may not be

easy, even if canned

software

packages are available. One

of the biggest problems with

incorporating PERT

occurred

in the 1960s when the Department of

Defense requested that its

customers

adopt

PERT/cost for relating cost

and schedules. This resulted in the

expenditure of

considerable

cost and effort on behalf of the

contractor to overcome the numerous

cost-

accounting

problems. Many contractors eventually

went to two sets of books;

one set

was

for program control (which

was in compliance with

standard company cost

control

procedures),

and a second set was created

for customer reporting.

Therefore, before

accepting

a PERT system, management

must perform a trade-off

study to determine if

the

results are worth the

cost.

28.3.2

Criticism of PERT:

The

criticism that most people

discover when using PERT

includes:

·

Time

and labor intensive effort is

required.

·

Upper-level

management decision-making ability is

reduced.

·

There

exists a lack of functional ownership in

estimates.

·

There

exists a lack of historical data

for timecost

estimates.

·

The

assumption of unlimited resources may be

inappropriate.

·

There

may exist the need for

too much detail.

28.4

Network

Fundamentals and

Terminology:

It

is important to know that the

major discrepancy with Gantt,

milestone, or bubble charts is

the

inability

to show the interdependencies between events and

activities. These

interdependencies

199

Project

Management MGMT627

VU

must

be identified so that a master

plan can be developed that

provides an up-to-date picture

of

operations

at all times and is easily understood by

all.

The

interdependencies are shown through the

construction of networks. Network

analysis can

provide

valuable information for

planning, integration of plans, time

studies, scheduling,

and

resource

management. The primary

purpose of network planning is to

eliminate the need

for

crisis

management by providing a pictorial

representation of the total

program.

The

following management information

can be obtained from such a

representation:

·

Interdependencies

of activities

·

Project

completion time

·

Impact

of late starts

·

Impact

of early starts

·

Trade-offs

between resources and

time

·

"What

if" exercises

·

Cost

of a crash program

·

Slippages

in planning/performance

·

Evaluation

of performance

As

we know that networks are

composed of events and activities. An

event is defined as the

starting

or ending point for a group

of activities, and an activity is the

work required to

proceed

from

one event or point in time to

another. Figure 28.1 below

shows the standard nomenclature

for

PERT networks. The circles represent

events, and arrows represent activities.

The numbers

in

the circles signify the specific events

or accomplishments. The number over the

arrow

specifies

the time needed (hours, days, months), to

go from event 6 to event 3.

The events need

not

be numbered in any specific order.

However, event 6 must take

place before event 3 can

be

completed

(or begin).

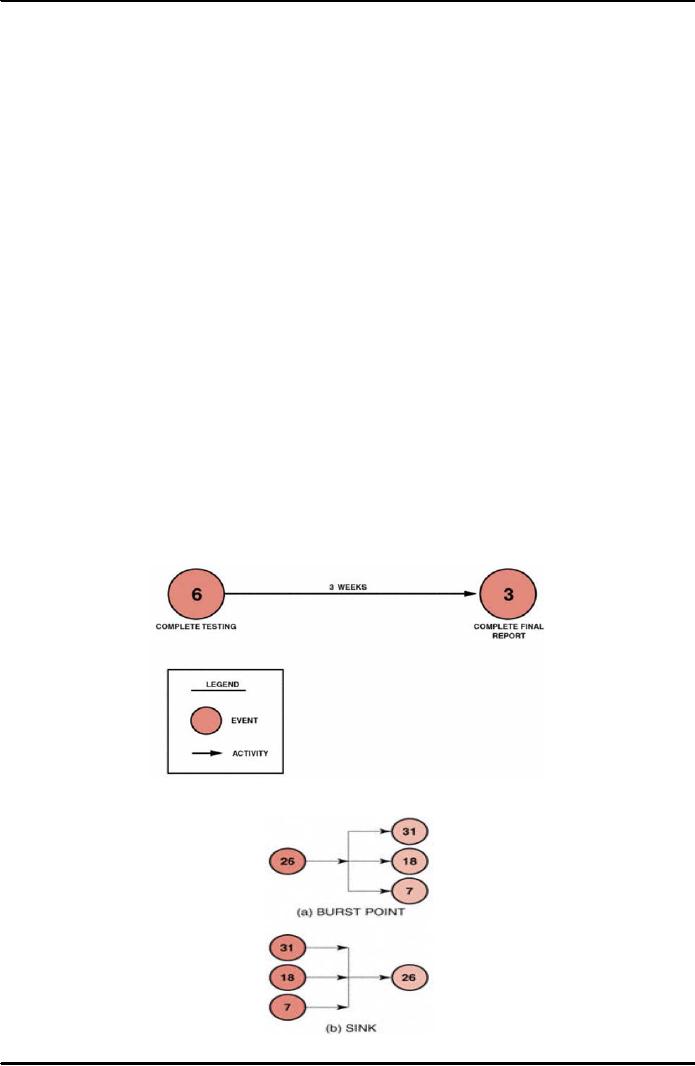

Figure

28.1: Standard PERT

Nomenclature

Figure

28.2: PERT

Sources (Burst Points) and

Sinks

200

Project

Management MGMT627

VU

As

depicted in Figure 28.2 (a)

above, event 26 must take place

prior to events 7, 18, and

31. In

Figure

28.2 (b), the opposite holds

true, and events 7, 18, and 31

must take place prior to

event

26.

Thus, it is similar to "and gates" used

in logic diagrams.

However,

these charts can be used to

develop the PERT network, as shown in

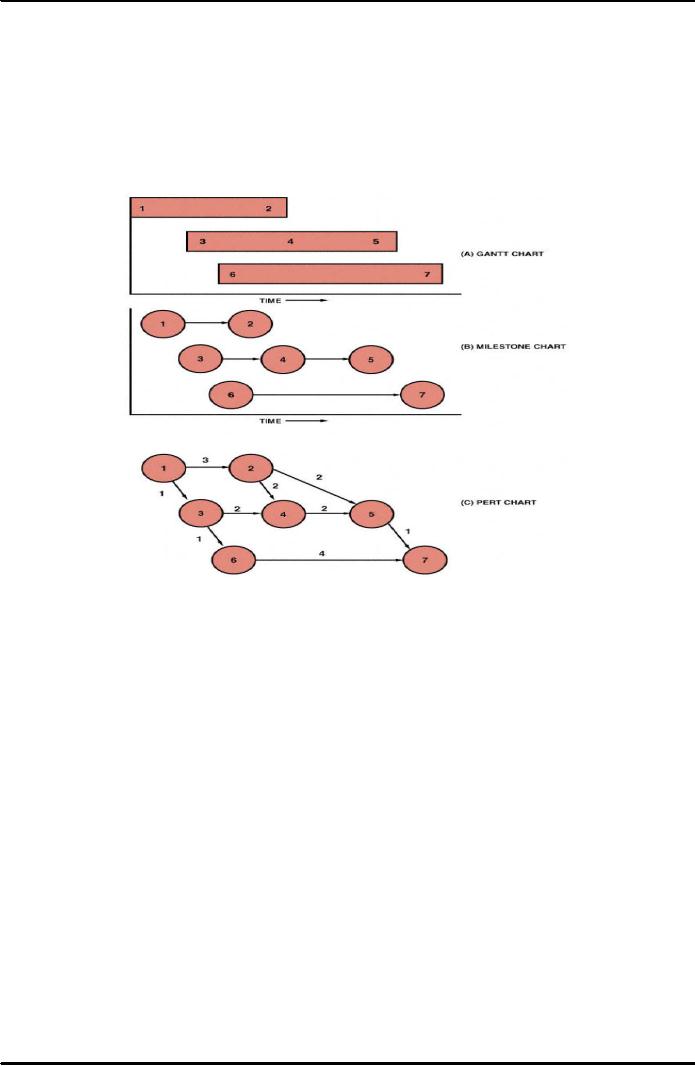

Figure 28.3

below.

The bar chart in Figure (A)

below can be converted to the

milestone chart in Figure

(B)

below.

By then defining the relationship between the

events on different bars in the

milestone

chart,

we can construct the PERT chart in Figure

(C) below.

Figure

28.3: Conversion

from Bar Chart to PERT

Chart

Basically

PERT is a management planning and control

tool. It can be considered as a road

map

for

a particular program or project in

which all of the major

elements (events) have been

completely

identified together with

their corresponding interrelations.

PERT charts are

often

constructed

from back to front because,

for many projects, the end date is

fixed and the

contractor

has front-end

flexibility.

It

is important to note here

that one of the purposes of constructing

the PERT chart is to

determine

how much time is needed to

complete the project. PERT, therefore,

uses time as a

common

denominator to analyze those elements

that directly influence the

success of the

project,

namely, time, cost, and

performance. The construction of the

network requires two

inputs.

First, a selection must be made as to

whether the events represent the

start or the

completion

of an activity. Event completions

are generally

preferred.

201

Project

Management MGMT627

VU

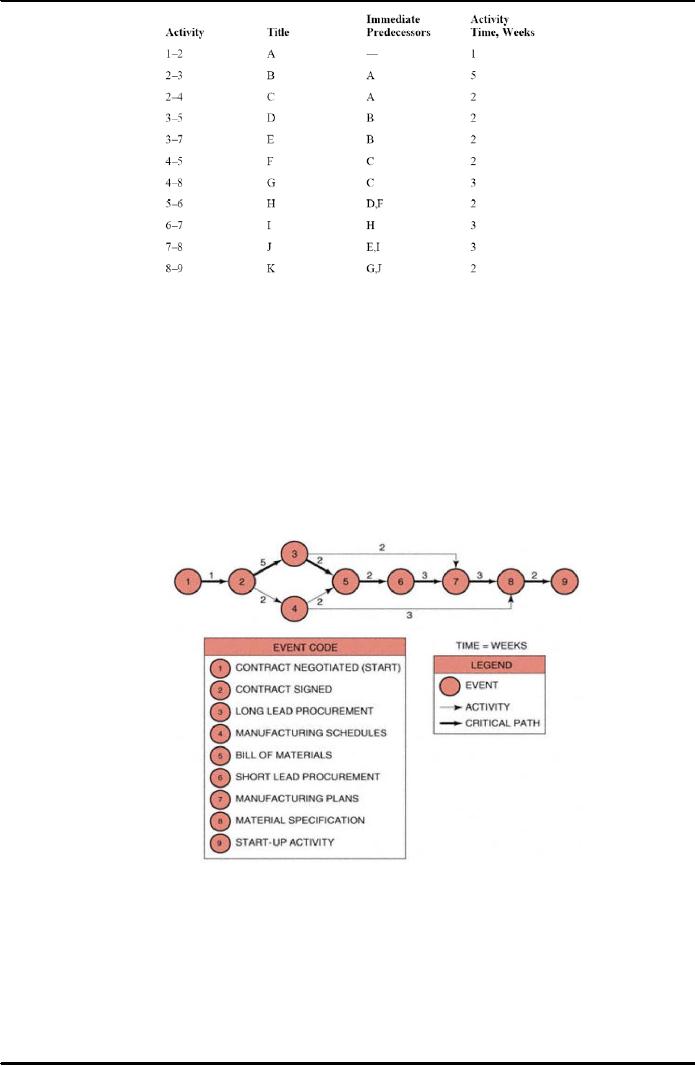

Table

28.1: Sequence

of Events

The

next step is to define the

sequence of events, as shown in Table

28.1 above, which

relates

each

event to its immediate

predecessor. Large projects can

easily be converted into

PERT

networks

once the following questions are

answered:

·

What

job immediately precedes

this job?

·

What

job immediately follows this

job?

·

What

jobs can be run

concurrently?

A

typical PERT network is shown in the

following figure

28.4.

Figure

28.4: Simplified

PERT Network

The

bold line represents the

critical path, which is established by

the longest time span

through

the

total system of events. The

critical path is composed of

events 12356789.

The

critical

path is vital for successful

control of the project because it

tells management two

things:

1.

Because

there is no slack time in any of the

events on this path, any

slippage will cause

a

corresponding slippage in the end date of

the program unless this

slippage can be

recovered

during any of the downstream events

(on the critical

path).

202

Project

Management MGMT627

VU

2.

Because

the events on this path are

the most critical for the

success of the project,

management

must take a hard look at

these events in order to

improve the total

program.

Therefore,

by using PERT we can now

identify the earliest possible dates on

which we can

expect

an event to occur, or an activity to

start or end. There is nothing

overly mysterious about

this

type of calculation, but

without a network analysis the

information might be hard to

obtain.

PERT

charts can be managed from

either the events or the activities.

For levels 13 of the

Work

Breakdown

Structure (WBS), the project manager's

prime concerns are the milestones,

and

therefore,

the events are of prime

importance. For levels

46 of the Work Breakdown

Structure

(WBS),

the project manager's concerns

are the activities.

28.5

Differences

Between PERT and

CPM:

Note

that the principles that we have

discussed so far apply not

only to PERT, but to CPM

as

well.

The nomenclature is the same for

both, and both techniques are

often referred to as

arrow

diagramming

methods, or activity-on-arrow networks.

The differences between PERT and

CPM

are

as follows:

·

PERT

uses three time estimates

(optimistic, most likely,

and pessimistic). From

these

estimates,

an expected time can be derived.

CPM uses one time

estimate that represents

the

normal

time (that is, better

estimate accuracy with

CPM).

·

PERT

is probabilistic in nature, based on a

beta distribution for each

activity time and a

normal

distribution for expected time

duration. This allows us to calculate

the "risk" in

completing

a project. CPM is based on a

single time estimate and is

deterministic in nature.

·

Both

PERT and CPM permit the use

of dummy activities in order to

develop the logic.

·

PERT

is used for Research and

Development projects where the risks in calculating

time

durations

have a high variability. CPM is

used for construction projects

that are resource

dependent

and based on accurate time

estimates.

·

PERT

is used on those projects, such as

Research and Development, where

percent

complete

is almost impossible to determine except at completed

milestones. CPM is used

for

those projects, such as construction,

where percent complete can be determined

with

reasonable

accuracy and customer

billing can be accomplished based on

percent complete.

28.6

Graphical

Evaluation And Review Technique

(GERT):

Graphical

Evaluation and Review Techniques

(GERT) are similar to PERT

but have the distinct

advantages

of allowing for looping,

branching, and multiple project end

results. With PERT

one

cannot

easily show that if a test

fails, we may have to repeat the

test several more times. With

PERT,

we cannot show that, based upon the

results of a test, we can

select one of several

different

branches to continue the project.

These problems are easily overcome

using GERT.

28.7

Dependencies

or Interrelationships:

There

are three basic types of

interrelationships or

dependencies:

1.

Mandatory

Dependencies (i.e., Hard

Logic):

These

are dependencies that cannot

change, such as erecting the

walls of a house

before

putting

up the roof.

2.

Discretionary

Dependencies (i.e., Soft

Logic):

These

are dependencies that may be

at the discretion of the project manager

or may

simply

change from project to

project. As an example, one does

not need to complete

the

entire bill of materials prior to

beginning procurement.

203

Project

Management MGMT627

VU

3.

External

Dependencies:

These

are dependencies that may be

beyond the control of the project

manager such as

having

contractors sit on your critical

path.

28.7.1

Dummy Activities:

It

is sometimes impossible to draw

network dependencies without

including dummy

activities.

Dummy activities are

artificial activities, represented by a

dotted line, and do

not

consume resources or require

time. They are added

into the network simply

to

complete

the logic.

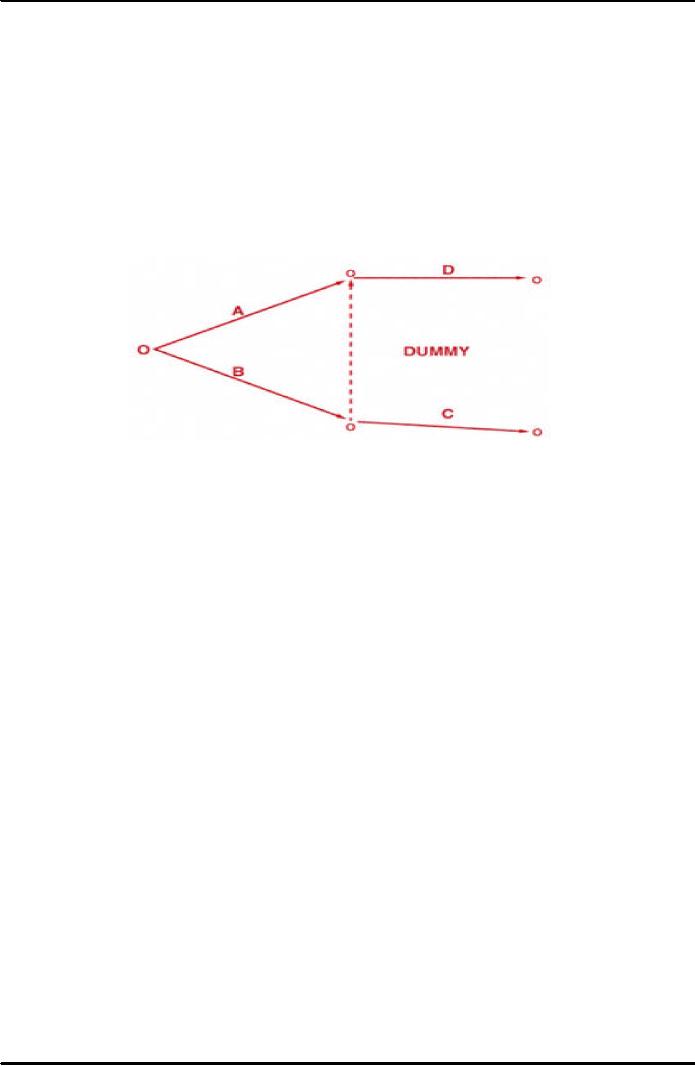

In

the Figure 28.5 below, the

dummy activity is required to show

that D is preceded by

A

and B.

Figure

28.5: Dummy

Activity

28.8

Slack

Time:

It

is essential to know that

since there exists only one path

through the network that is

the

longest,

the other paths must be

either equal in length to or shorter

than that path.

Therefore,

there

must exist events and

activities that can be completed

before the time when they

are

actually

needed. The time

differential between the scheduled

completion date and the

required

date

to meet critical path is

referred to as the slack time. In Figure

28.4, event 4 is not on

the

crucial

path. To go from event 2 to

event 5 on the critical path requires

seven weeks taking

the

route

235. If route 245 is

taken, only four weeks

are required. Therefore,

event 4, which

requires

two weeks for completion,

should begin anywhere from

zero to three weeks after

event

2

is complete. During these three weeks,

management might find another

use for the resources

of

people, money, equipment, and

facilities required to complete event

4.

Therefore,

the critical path is vital

for resource scheduling and

allocation because the

project

manager,

with coordination from the

functional manager, can reschedule

those events not on

the

critical

path for accomplishment during

other time periods when

maximum utilization of

resources

can be achieved, provided that the

critical path time is not

extended. This type of

rescheduling

through the use of slack times provides

for a better balance of

resources

throughout

the company, and may possibly

reduce project costs by

eliminating idle or

waiting

time.

204

Table of Contents:

- INTRODUCTION TO PROJECT MANAGEMENT:Broad Contents, Functions of Management

- CONCEPTS, DEFINITIONS AND NATURE OF PROJECTS:Why Projects are initiated?, Project Participants

- CONCEPTS OF PROJECT MANAGEMENT:THE PROJECT MANAGEMENT SYSTEM, Managerial Skills

- PROJECT MANAGEMENT METHODOLOGIES AND ORGANIZATIONAL STRUCTURES:Systems, Programs, and Projects

- PROJECT LIFE CYCLES:Conceptual Phase, Implementation Phase, Engineering Project

- THE PROJECT MANAGER:Team Building Skills, Conflict Resolution Skills, Organizing

- THE PROJECT MANAGER (CONTD.):Project Champions, Project Authority Breakdown

- PROJECT CONCEPTION AND PROJECT FEASIBILITY:Feasibility Analysis

- PROJECT FEASIBILITY (CONTD.):Scope of Feasibility Analysis, Project Impacts

- PROJECT FEASIBILITY (CONTD.):Operations and Production, Sales and Marketing

- PROJECT SELECTION:Modeling, The Operating Necessity, The Competitive Necessity

- PROJECT SELECTION (CONTD.):Payback Period, Internal Rate of Return (IRR)

- PROJECT PROPOSAL:Preparation for Future Proposal, Proposal Effort

- PROJECT PROPOSAL (CONTD.):Background on the Opportunity, Costs, Resources Required

- PROJECT PLANNING:Planning of Execution, Operations, Installation and Use

- PROJECT PLANNING (CONTD.):Outside Clients, Quality Control Planning

- PROJECT PLANNING (CONTD.):Elements of a Project Plan, Potential Problems

- PROJECT PLANNING (CONTD.):Sorting Out Project, Project Mission, Categories of Planning

- PROJECT PLANNING (CONTD.):Identifying Strategic Project Variables, Competitive Resources

- PROJECT PLANNING (CONTD.):Responsibilities of Key Players, Line manager will define

- PROJECT PLANNING (CONTD.):The Statement of Work (Sow)

- WORK BREAKDOWN STRUCTURE:Characteristics of Work Package

- WORK BREAKDOWN STRUCTURE:Why Do Plans Fail?

- SCHEDULES AND CHARTS:Master Production Scheduling, Program Plan

- TOTAL PROJECT PLANNING:Management Control, Project Fast-Tracking

- PROJECT SCOPE MANAGEMENT:Why is Scope Important?, Scope Management Plan

- PROJECT SCOPE MANAGEMENT:Project Scope Definition, Scope Change Control

- NETWORK SCHEDULING TECHNIQUES:Historical Evolution of Networks, Dummy Activities

- NETWORK SCHEDULING TECHNIQUES:Slack Time Calculation, Network Re-planning

- NETWORK SCHEDULING TECHNIQUES:Total PERT/CPM Planning, PERT/CPM Problem Areas

- PRICING AND ESTIMATION:GLOBAL PRICING STRATEGIES, TYPES OF ESTIMATES

- PRICING AND ESTIMATION (CONTD.):LABOR DISTRIBUTIONS, OVERHEAD RATES

- PRICING AND ESTIMATION (CONTD.):MATERIALS/SUPPORT COSTS, PRICING OUT THE WORK

- QUALITY IN PROJECT MANAGEMENT:Value-Based Perspective, Customer-Driven Quality

- QUALITY IN PROJECT MANAGEMENT (CONTD.):Total Quality Management

- PRINCIPLES OF TOTAL QUALITY:EMPOWERMENT, COST OF QUALITY

- CUSTOMER FOCUSED PROJECT MANAGEMENT:Threshold Attributes

- QUALITY IMPROVEMENT TOOLS:Data Tables, Identify the problem, Random method

- PROJECT EFFECTIVENESS THROUGH ENHANCED PRODUCTIVITY:Messages of Productivity, Productivity Improvement

- COST MANAGEMENT AND CONTROL IN PROJECTS:Project benefits, Understanding Control

- COST MANAGEMENT AND CONTROL IN PROJECTS:Variance, Depreciation

- PROJECT MANAGEMENT THROUGH LEADERSHIP:The Tasks of Leadership, The Job of a Leader

- COMMUNICATION IN THE PROJECT MANAGEMENT:Cost of Correspondence, CHANNEL

- PROJECT RISK MANAGEMENT:Components of Risk, Categories of Risk, Risk Planning

- PROJECT PROCUREMENT, CONTRACT MANAGEMENT, AND ETHICS IN PROJECT MANAGEMENT:Procurement Cycles