|

Chapter

Three

LIGHT

EMITTERS

Introduction

to Light Emitters

Unlike

the limited number of

useable light detectors, there is a

wide variety of light

emitters that

you can

use for optical

through-the-air communications. Your

communications system will

depend

much

more on the type of light

source used than on the

light detector. You should

choose the light

source

based on the type of

information that needs to be

transmitted and the distance you

wish cover

to

reach the optical receiver. In

all cases the light source

must

be

modulated (usually turned on

and

off

or varied in intensity) to transmit

information.

The

modulation rate will determine

the

maximum

rate information can be

transmitted.

You may have to make

some

tradeoffs

between the modulation

rates

needed,

the distance to be covered and

the

amount

of money you wish to

spend.

Many

light sources listed below

are useful

for

low to medium speed

modulation rates

and

can have ranges up to several

miles. A

few

others are ideal for

low speed

telemetry

transmission that can reach

beyond

50 miles. If you need high

speed

Samples

of Emitters

information

transmission, there are only

a

few

choices, and those tend to be expensive.

But, as the technology

improves the prices

should

come

down. I have also described

some of the latest devices

that may become available to

the

experimenter

in a few years, but only

demonstration devices exist

today.

Light

Emitting Diodes

(LEDS)

For

most through-the-air communications

applications the infrared

light emitting diode (IRLED)

is

the

most common choice. Although

visible light emitting devices do

exist, the infrared parts

are

generally

chosen for their higher

efficiency and more favorable

wavelength, especially when

used

with

silicon photodiode light

detectors.

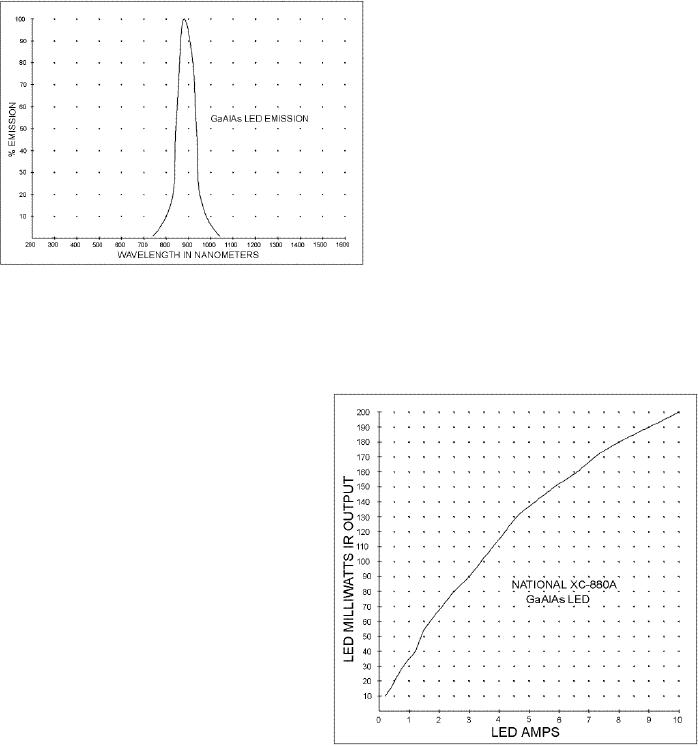

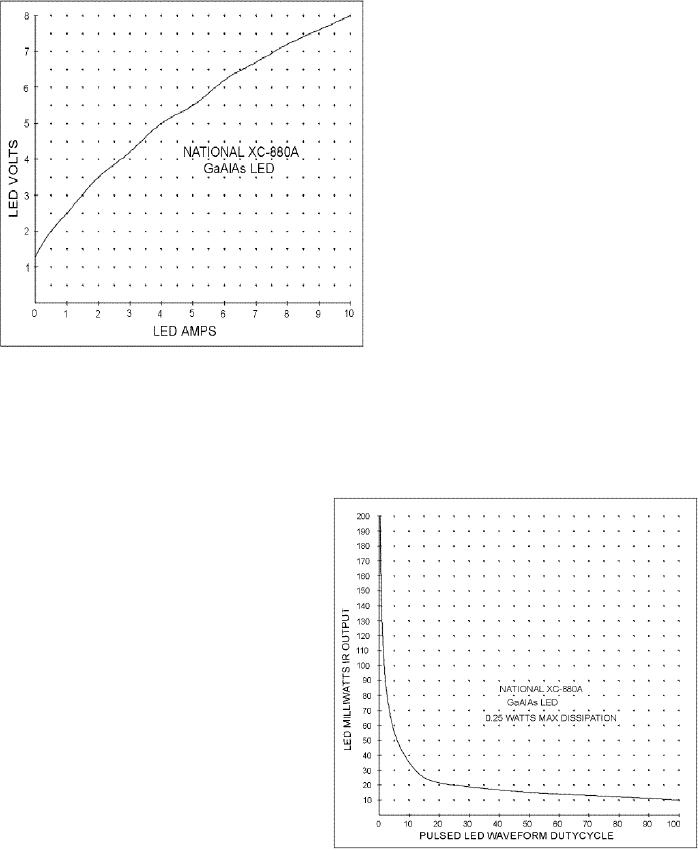

GaAlAs

IR LED

GaAlAs

(gallium, aluminum arsenic)

infrared LEDs are the

most widely used modulated

IR light

sources.

They have moderate electrical to

optical efficiencies, (at

low currents 4%), and

produce

light

that matches the common

silicon PIN detector

response curve (900nm). Most

devices can be

pulsed

at high current levels, as

long as the average power

does not exceed the

manufacturer's

maximum

power dissipation specification

(typically 0.25 watts). Some

devices can be pulsed up to

10

amps, if the duty cycle

(ratio of on time to the

time between pulses) is less

than 0.2% (0.002:1

ratio).

Some of the faster devices

have response times that

allow them to be driven with

current

Page

23

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson, PE

pulses

as short as 100 nanoseconds

but

most

devices require at least

900

nanoseconds.

At a current level of about

6

amps

a quality device can emit

about 0.15

watts

of infrared light. However, at

higher

current

levels their efficiency is

generally

poor,

dropping to less than 0.5%

(See

Figures

3a, 3b, 3c and 3d.)

Many

resemble

the commonly used visible

LEDs

and

will typically be packaged in

molded

plastic

assemblies that have small

3/16"

lenses

at the end. The position of

the

actual

LED chip within the

package will

determine

the divergence (spreading

out)

of

the exiting light. The

typical T-1 3/4

Figure

3a

style

device will have a half

angle divergence ranging

from 15 to 40 degrees. They

are low cost,

medium

speed (up to 1 million pulses per second)

sources, with long operating

lifetimes (typically

greater

than 100,000 hours).

They

are a good choice for short

and

medium

distance control links and

general

communications

applications. When

used

with

a large lens, a single

device can be

used

for a communications system

with a

multi-mile

range. Multi-device arrays can

also

be constructed to transmit

information

over

wider areas or longer distances.

They

generally

cost between $0.30 to $2.00

each

and

are

available

from

many

manufacturers.

GaAs

IR LED

These

devices are the older and

less

efficient

cousin to the GaAlAs

devices.

They

come in all styles and shapes.

The

more

useful devices have smaller

emitting

surfaces

than GaAlAs LED's,

permitting

narrow

divergence angles with

small

Figure

3b

lenses.

Also, the small emitting

areas make

them

very useful for fiber

optic applications. Some

commercial devices have miniature

lenses

cemented

directly to the semiconductor

chip to produce a small

exiting light angle

(divergence

angle).

In conjunction with a small

lens (typically 0.5") such

devices can launch light with a

narrow

divergence

angle (0.5 degrees). The

most important feature of

the GaAs LED is its

speed. They are

generally

10 times faster than GaAlAs

LED's but many only

produce 1/6 as much light.

They are

often

picked when medium speed

transmission over short

distances is required. Their

price is

typically

a little more than the

GaAlAs LED's, even though

they use an older

technology. They will

cost

between $2.00 to

$25.00.

Page

24

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson, PE

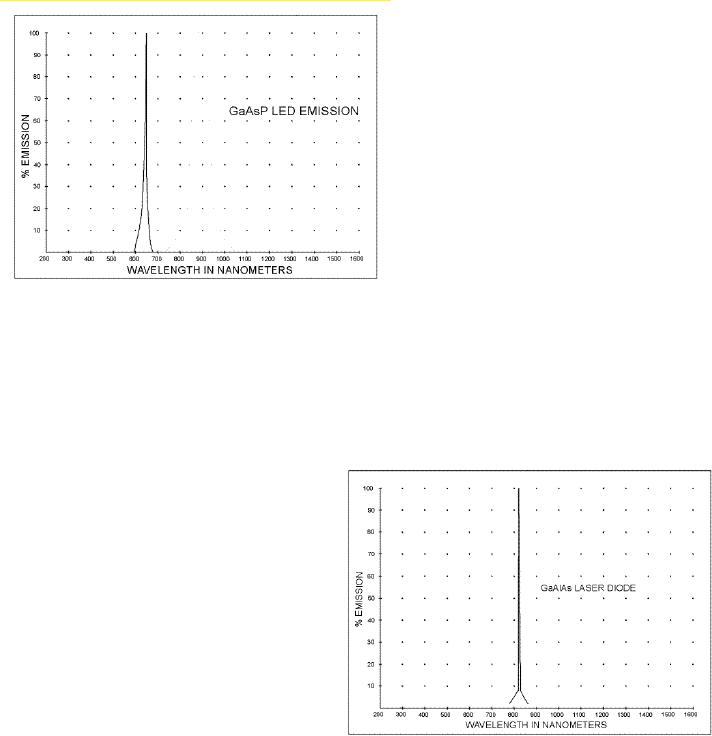

GaAsP

Visible Red LEDs

Although

not as efficient as the

infrared

devices

some visible red LEDs

(Figure

3d-1)are now

available, that might

find

limited

use in some short range

through-

the-air

applications. Some so called

"super

bright"

LEDs boast high light

output.

However,

even the brightest

components

will

still produce only 1/3 as

much light as

a

quality infrared

part.

Also,

since their light is a visible red

color,

an

automatic 2:1 penalty will be paid

when

the

devices are used with a

standard

silicon

detector that has a weaker

response

to

red light. The visible red

LEDs are

generally

faster (up to 2 million pulses

per

second)

than IR components and can

therefore

be used for medium

speed

Figure

3c

applications.

Also, since their light

is

visible,

they are much easier to

align than invisible IR devices,

especially when the devices

are used

with

lenses.

Solid

State Semiconductor

Lasers

GaAs

(Hetrojunction) Lasers

These

devices have been around since

the

1960s

and can produce very powerful

light

pulses.

Some devices are able to

launch

light

pulses in excess of 20 watts, which

is

some

200 times more powerful than

a

typical

GaAlAs LED. But, these

devices

can

only be driven with duty

cycles, less

than

0.1% (off time must be 1000

times

longer

than on time). Also, their

maximum

pulse

width must be kept short

(typically

less

than 200 nanoseconds) even

under

low

pulse rate applications.

However,

despite

their limitations these devices

can

be

used in some voice

transmitter systems

if

some careful circuit designs

are used.

As

in most semiconductor lasers, the

GaAs

laser

does require a minimum

current level

Figure

3d

(typically

10 to 20 amps) before it begins

emitting

useable light. Such high

operating currents demand more

complicated drive

circuits.

Despite

a 10:1 sensitivity reduction,

caused by the rather narrow

emitted pulses (see receiver

circuit

discussion),

the more powerful light

pulses available from GaAs

lasers can increase the

useful range

of

a communications system by a factor of

about 3, over a typical

transmitter using a single

LED. In

Page

25

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson, PE

addition,

since their emitting spot sizes

are

very

small, they can also be focused

into

very

tight beams using rather

small lenses.

In

addition, since their spectral

widths are

very

narrow the matching light

detector

circuit

can use an optical band pass

filter

to

reduce the noise levels associated

with

ambient

light (see receiver circuit

section).

For

low speed and

long distance

applications,

the GaAs laser should

be

considered.

However, they do have

some

disadvantages.

They typically cost

much

more

than a GaAlAs LED (up to

$75).

They

have shorter lifetimes (may

only last

a

few hundred hours) and are

sensitive to

Figure

3d-1

temperature.

Therefore, they require a

carefully designed transmitter

circuit that can switch 20

or

more

amps at high speeds and can

compensate for changes in

operating temperature.

GaAlAs

(CW) Lasers

These

are the latest in infrared

light emitting semiconductor devices and

are rapidly maturing.

The

first

wide spread application for

these devices was in audio compact

disk players and CD-

ROM

computer disk drives. They

are also

being

used in some computer

laser

printers,

bar code readers and FAX

machines.

They have very small

emitting

areas,

can produce peak power

levels in

excess

of 0.2 watts and have

narrow

spectral

bandwidths (see Figure

3e.)

The

most

important improvement over

other

light

sources is that they can be

modulated

at

frequencies measured in

gigahertz.

However,

as in any new technology

they

are

still rather expensive. Low

power units

that

emit less than 0.01

watts of 880nm

infrared

light, sell for about

$20.00. Some

of

the more powerful devices can cost

as

Figure

3e

much

as $20,000 each. Although the

use of a laser in a communications system

might give a project

a

high tech sound, a much

cheaper IR LED will almost

always out-perform a low

power laser

(typical

LED will be able to emit 10 times

more light at 1/10 the

cost) in low to medium

speed

applications.

But, when very high-speed

modulation rates (up to 1

billion pulses per second) are

needed,

these devices would be a good

choice.

Although

expensive now, these devices

should come down in price

over the next few years.

They

will

also most likely be available at

higher power levels too.

But, until then, their

advantages do not

justify

their expense and the more

useful high power units

are beyond the reach of

practical

experimental

designs. I suggest using these devices

only when necessary.

Page

26

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson, PE

Surface

Emitting Lasers

(VCSEL)

These

devices are just now

beginning to appear in some catalogs.

Many companies have

been

experimenting

with these latest

semiconductor devices since about 1988.

Their small size and

high

efficiency

make them very suitable for

some applications. They are

mostly used in optical

fiber

communications.

Instead of being grown as

single chip emitters, these

devices are fabricated

into

large

arrays of very small

individual laser sources sharing a

common substrate. Since the

individual

laser

diode emitters can be as small as one

micron (1/10,000cm) as many as 100

million separate

devices

could be placed into a 1cm X

1cm area.

The

output efficiency (electrical

power to light power) has

been reported to be about

40%, with

each

tiny device emitting about

0.003 watts. Although each

device may emit only a

small amount of

light,

when used as an array, 100

million such devices could

launch some 100,000 watts of IR

light

from

about 200,000 watts of electricity. Of

course, cooling such a powerful

array would be a real

challenge,

if not impossible. But,

perhaps smaller arrays could

be placed into common

semiconductor

packages for easy mounting

and cooling. Maybe a 0.1-watt

device would be placed

into

inexpensive LED style

packages. Other devices may be

mounted in better heat

conducting

metal

packages to allow perhaps 100

watts of light to be emitted. Since

their maximum

modulation

rates

have been measured in the

multi-billion pulses per second rate,

surface-emitting lasers

would

be

ideal for many future

through-the-air communications

applications. They would

especially be

useful

in broadcasting optical information over

a citywide area, where very

powerful high-speed

light

sources are needed. A

10,000-watt source, emitting light in a

specially shaped

360-degree

pattern,

might be able to transmit information

over an area covering some

500 square miles. Such

a

broadcasting

system might be used to

transmit library type

information from large

centralized

databases.

Externally

Excited Solid State

Lasers

Some

of the very first lasers

made were the Ruby and YAG

lasers. Most of these lasers

are excited

externally

using large xenon flash

tubes that are positioned

around the central glass

laser rod. A

small

portion of the light from

the xenon flash excites

the specially positioned rod

material, forming

short

coherent light pulses. Although

these lasers are capable of

emitting very power light

pulses,

with

very narrow divergence angles,

they are generally much

too expensive and too

complicated for

the

average experimenter. They

would therefore find very

limited use in earth-bound

optical

communications.

However, some scientists

believe that the extremely

powerful light pulses

that

these

devices are capable of producing,

might be useful in transmitting

information into very

deep

space.

Since some pulsed lasers

have been reported to launch

light pulses approaching one

terawatt

(1000

billion watts), low speed

communications might be possible to a range of

several light years

(one

light year = 6 trillion

miles). Such a feat would be

very difficult to accomplish

with microwave

techniques.

Gas

Lasers

Helium-neon,

carbon dioxide and argon are

the more common types of

gas lasers. The light

emitted

from

a gas arc, inside a glass

tube, is bounced back and

forth through the excited

gas using specially

fabricated

mirrors. A portion of the

light is allowed to escape

through one of the mirrors

and

emerges

as very monochromatic (one

wavelength) and highly coherent

(same phase) light.

Such

lasers

have narrow divergence angles

(typically less than 0.1

degrees) but have very

low conversion

efficiencies

(much less than 0.1%).

They are also expensive and

bulky that makes them

impractical

for

most optical communications

applications. Some published

designs that did

provide

experimental

optical communications using

helium-neon lasers were

designed to transmit

voice

Page

27

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson, PE

audio

information over a range of only a

few miles. The modulation

technique was to vary the

gas

arc

current that then produced a

light intensity modulation.

However, the extra cost and

relative low

power

that resulted usually did

not warrant the trouble. A

properly designed system

using a single

LED

will usually out perform any

short-range helium-neon laser

communications system at a

fraction

of the cost.

Although

too expensive for the

experimenter, some gas

lasers have been used by

the military for

many

years. In particular, carbon dioxide

lasers, that emit long

infrared wavelengths

(10,000

nanometers),

have been used in some

military targeting systems. The

long infrared wavelength

can

penetrate

smoke and fog better than

visible or near IR lasers. Also, the

Navy has been

experimenting

with some blue-green laser

light to attempt to provide

communications to

submarines

deep under water. But,

overall gas lasers fall

short of the ideal for

practical through-the-

air

communications.

Fluorescent

Light Sources

Fluorescent

Lamps

Fluorescent

lamps work on the principle

of

"fluorescence"

and because of their

low

cost

have

many

through-the-air

applications.

An electrical current

passed

through

a mercury vapor inside a

glass

tube

causes the gas discharge to

emit

ultraviolet

"UV" light. The UV

light

causes

a mixture of phosphors, painted

on

the

inside wall of the tube, to

glow at a

number

of visible light wavelengths

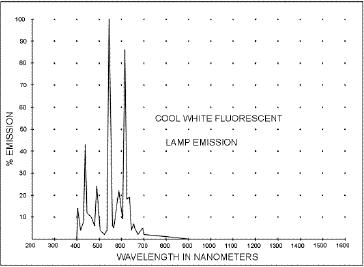

(see

Figure

3f.) The

electrical to optical

conversion

efficiency of these

light

sources

is fairly good, with about 3

watts

of

electricity required to produce

about 1

watt

of light. A cathode electrode at

each

Figure

3f

end

of the lamp that is heated

by the discharge current, aids in

maintaining the discharge

efficiency,

by

providing rich electron sources. By

turning on and off the

electrical discharge current, the

light

being

emitted by the phosphor, can be

modulated. Also, by driving

the tubes with higher

than

normal

currents and at low duty

cycles, a fluorescent lamp can be

forced to produce powerful

light

pulses.

However, like the pulse

techniques used with LEDs,

the fluorescent lamp pulsing

techniques

must

use short pulse widths to

avoid destruction of the

lamp.

To

modulate a fluorescent lamp to

transmit useful information,

the negative resistance

characteristic

of

the mercury vapor discharge

within the lamp must be

dealt with. This requires

the drive circuit to

limit

the current through the

tube. The two heated cathode

electrodes of most lamps also require

the

use

of alternating polarity current pulses to

avoid premature tube

darkening. The typical

household

fluorescent

lighting uses an inductive

ballast method to limit the

lamp current. Although such

a

method

is efficient, the inductive

current limiting scheme

slows the rise and fall

times of the

discharge

current through the tube and

thus produces longer then

desired light pulses. To achieve

a

short

light pulse emission, a

resistive current limiting

scheme seems to work better.

In addition,

there

seems to be a relationship between

tube length and the maximum

modulation rate. Long

tubes

do

not respond as fast as shorter

tubes. As an example, a typical

48" 40 watt lamp can be

modulated

Page

28

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson, PE

up

to about 10,000 pulses per second,

but

some

miniature 2" tubes can be driven

up

to

200,000 pulses per second. The

main

factor

that ultimately limits the

modulation

speed

is the response time of the

phosphor

used

inside the lamp. Most

visible

phosphors

will not allow pulsing

much

faster

than about 500,000 pulses per

second.

The visible light emitted by

the

typical

"cool white" lamp is also

not ideal

when

used with a silicon

photodiode.

However,

some special infrared

light

emitting

phosphors could be used

to

increase

the relative power output

from a

fluorescent

lamp, which may also

produce

Figure

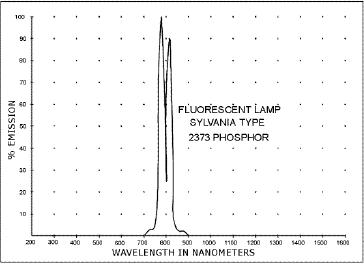

3g

faster

response times. (see

Figure

3g.)

If

a conventional "cool white"

lamp is used, a 2:1 power

penalty will be paid due to the

broad

spectrum

of visible light being

emitted (see Figure

3f.) This

results since the visible

light does not

appear

as bright to a silicon light

detector as IR light (see

section on light detectors).

Also, light

detectors

with built-in visible

filters should not

be

used, since they would not

be sensitive to the

large

amount of visible light

emitted by the lamps.

Although the average

fluorescent lamp is not

an

ideal

light source, the relative

low cost and the large

emitting surface area make it

ideal for

communications

applications requiring light to be

broadcasted over a wide

area. Experiments

indicate

that about 20 watts of light

can be launched from some

small 9-watt lamps at

voice

frequency

pulse rates (10,000/sec).

Such power levels would

require about 100 IR LEDs

to

duplicate.

But, the large surface

emitting areas of fluorescent

lamps makes them impractical

for

long-range

applications, since the light

could not be easily

collected and directed into a

tight beam.

(For

additional information see

section on fluorescent lamp

transmitter/receiver circuits.)

Cathode

Ray Tubes (CRT)

CRTs

work somewhat like

fluorescent lamps, since they

too use fluorescence

emission techniques.

Electrons,

emitted from a heated cathode end of

the cathode ray vacuum tube,

are accelerated

toward

the anode end by the force

of a high voltage applied

between the cathode and

anode

electrodes.

Before hitting the anode

screen, the electrons are

forced to pass through a

phosphor

painted

onto the inside of the

screen. In response to the high-speed

electrons, the phosphor

emits

light

at various wavelengths. A voltage

applied to a special metal grid near

the tube's cathode end is

used

to modulate the electron

beam and can thus produce a

modulation in the emitted

light. This

principle

is used in most computer and TV

screens. Since the electron

beam can be modulated at

very

high rates, the light source

modulation rate is limited only by

the response time of

the

phosphor

used. Depending on the type

of phosphor, the electrical to

optical efficiency can be as

high

as 10%. Some specially made

cathode ray tubes produce powerful broad

(unfocused) electron

beams

that illuminate the entire

front screen of the CRT

instead of a small dot. Such tubes can

yield

powerful

light sources, with large

flat emitting areas. A

variation on the usual

television type CRT

design

positions a curved phosphor

screen at the back of the

vacuum tube and places the

cathode

electrode

at the front or side of a

clear glass screen (some

portable Sony TVs use

such CRTs). This

technique

increases the overall

efficiency, since it allows the

light from the phosphor to

exit from

the

same side as the electron

source. With the aid of external

cooling, such techniques

could create

Page

29

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson, PE

very

powerful light sources that

might be able to launch tens of thousands

of watts of light,

pulsed

at

rates exceeding tens of millions of

light pulses per second. Although the

typical experimenter

may

not be interested in such

light power levels it does

raise some interesting

possibilities for use

in

city

wide optical

communications.

Gas

Discharge Sources

Xenon

Gas Discharge Tubes

The

most common form of this

class of

light

source is the electronic camera

flash.

These

devices are some of the

most

intense

light sources available to

the

experimenter

and have many

interesting

applications.

The discharge lamps

are

typically

made from a glass tube

with a

metal

electrode installed at each

end. They

are

filled with xenon gas at

about one

atmosphere

of pressure (14psi). The

gas

inside

the tube can be made to glow

with

very

high intensity when an

electrical

current

is passed through it.

Xenon

Lamps

As

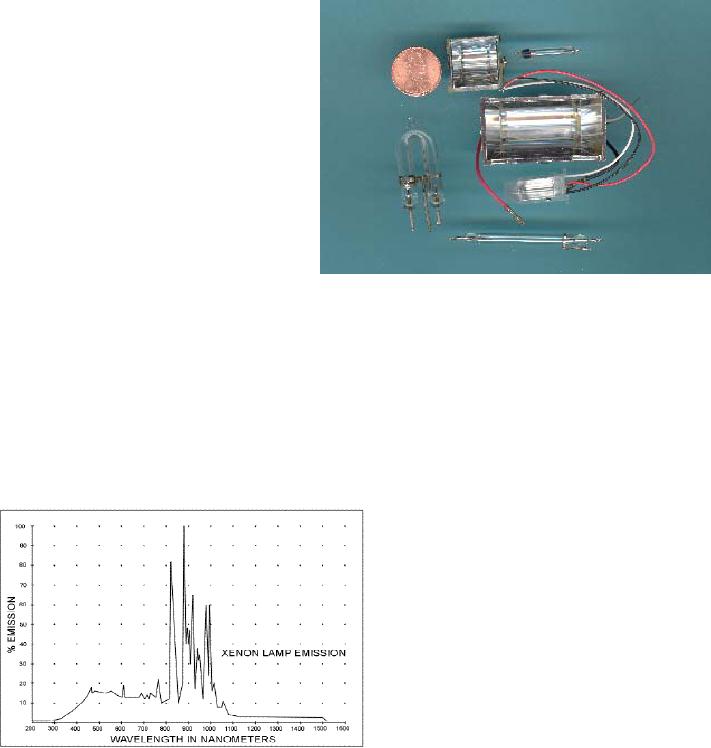

illustrated in Figure

3h, the

xenon arc

emits

light over a broad spectrum

with some large peaks in

the near infrared range. The

electrical to

optical

conversion is fairly good. A

typical camera flash can

produce about 2,000 watts of

light

from

about 10,000 watts of

electrical power (20%

efficiency). Some specially

made discharge tubes

can

generate flashes that exceed

one million watts of light

power. As in fluorescent lamps,

the

minimum

flash duration is somewhat dependent on

the length of the discharge

tube. A typical

camera

flash tube has an electrode

gap of about 15mm (0.6") and

will usually produce a

flash,

which

lasts about one millisecond. The

energy used to produce the

short flash comes

from

discharging

a special capacitor, charged to

several

hundred volts. By decreasing

the

size

of the capacitor (say to 6

microfarads)

and

increasing the voltage (say

to 300

volts)

the camera flash tube can be

made

to

produce flashes as short as

20

microseconds.

Shorter discharge flashes

are

only possible by using specially

made

discharge

tubes with very narrow

electrode

gaps

(0.5mm). These narrow gap

lamps

can

produce flashes as short as one

half

microsecond.

However, the physics of

the

xenon

gas arc prevents flashes

much

shorter.

Figure

3h

Flash

rates up to 10,000 per second

are

possible

with the short gap

lamps, but the typical

camera flash tube can't be

pulsed much faster

than

about

100 flashes per second. Since some special

high speed lamps can

dissipate up to 75 watts of

average

power, it is possible to design an optical

voice information transmitter

which could launch

Page

30

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson, PE

as

much as 1000 watts of light

with a narrow divergence.

Such a transmitter would

certainly have

some

long-range possibilities. However,

most xenon discharge lamps

are more useful for

low speed

and

long-range applications, requiring

very powerful light pulses.

Many years ago, I constructed

a

demonstration

telemetry system that

launched very powerful light

pulses at a low data rate that

had

a

useable range of 50 miles. (See

discussion on long-range telemetry

transmitters using xenon

flash

sources.)

Nitrogen

Gas (air) Sparks

For

very powerful and very short

light pulse applications, a

simple electrical spark in air can

be

used.

Some simple systems use two

closely spaced (0.5mm) electrodes

(usually made of

tungsten)

in open air. With

sufficient

voltage,

the air between the

electrodes can

be

made to ionize briefly,

forming a small

spark.

Some gas barbecue grill

igniters

that

use piezoelectric crystals to

produce

the

needed high voltage, can be

modified

to

produce useful sparks

for some

experiments.

Commercially made

nitrogen

spark

sources claim to generate

light

flashes

that pack about 100,000 watts

of

light

power into short 5

nanosecond

pulses.

The

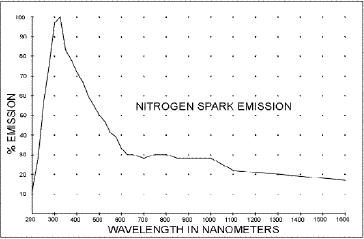

nitrogen (air) arc emits a

broad

Figure

3i

spectrum

of light with large peaks in

the

visible

blue and invisible ultraviolet

(see Figure

3i.) Such a

spectrum is not ideal when

used with

silicon

detectors. But the small

emission areas of the sparks

allow simple lenses or

mirrors to be

used

to form very tight

divergence angles. But, the

air ionization (sparking) can be

become very

unstable

at high pulse rates, without

using specially made discharge tubes and

drive circuits.

Therefore,

the sparks are best

used for powerful, very

short pulse applications

that demand only low

pulse

rates. Optical radar, electronic distance

measurements, air turbulence monitors and

wind shear

analysis

are some possible uses for

such a light source. You shouldn't be

fooled by the

seemingly

dim

appearance of these light

emitters. To our human eyes

the tiny flashes may

not seem very

bright,

but to a fast detector they

can be very powerful. However, to take

advantage of these unique

pulses,

a fast light detector and an

equally fast amplifier must

be used. Since few experiments

have

been

conducted with these unique

light sources, it is a great area for

the experimenter to see

what

can

be done.

Other

Gas Discharge Sources

Glass

discharge tubes filled with Cesium,

Krypton or Rubidium will all

produce lots of

infrared

light.

Krypton behaves much like

Xenon and has a very similar

emission output. Cesium

and

Rubidium

are both semi-liquids at

room temperatures and can be operated

under high or low

pressures

in a discharge lamp. Such lamps

might be constructed in a similar

manner to the more

common

yellow color sodium vapor

street lamp. Cesium, in particular,

appears to be a good

candidate

for some experimentation in

developing some powerful

light sources with high

peak

power

outputs. Since kilowatt size sodium

vapor street lamps are being

manufactured, perhaps

similar

lamps using cesium could be

made. Such lamps might be

able to produce multi-kilowatts of

modulated

infrared light using pulse

methods.

Page

31

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson, PE

External

Light Modulators

Ferroelectric

light valves, modulated

mirror arrays, piezoelectric

shutters, Kerr cells, Pockels

cells,

Bragg

cells and liquid crystals

are all light modulators.

They can be used to intensity

modulate light

being

emitted by an external source as it

passes through them or

reflects off them. The

light can

originate

from incandescent lamps, CW xenon

gas arc lamps, light from a

gas laser or even

focused

sunlight.

Although usually very

expensive, some of the devices can be

used to produce

powerful

modulated

light signals at high pulse

rates.

Liquid

crystal modulators are

perhaps the slowest of the

group. Most can't be driven

much faster

than

about 100 flashes per second.

Ferroelectric light valves and

piezoelectric shutters are a

little

faster

and can be pushed to perhaps 10,000

flashes per second. Kerr cells,

Bragg cells and

Pockel

cells,

on the other hand, are

known to be very fast.

However, they work best

when used with laser

light

at a specific wavelength and at narrow

angles. Some of these devices can

modulate the light

from

a laser at rates beyond 100 million

pulses per second. But, most of these

devices are very

expensive,

are complicated and are

therefore impractical for

the average

experimenter.

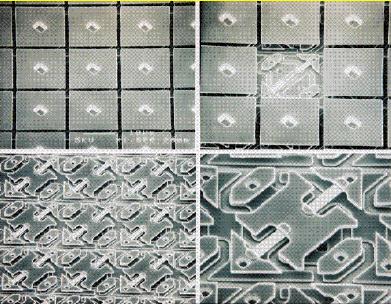

A

new device developed by

Texas

Instruments

(Figure

3j) has

some

interesting

possibilities. The

technology

was

originally developed for

flat panel

computer

and TV displays, but

the

techniques

might be useful for

optical

communications.

TI's process fabricates

a

large

array of very small mirrors

that can

be

moved using a voltage

difference

between

the mirror and an area

behind the

mirror.

Like tiny fans, each

mirror would

wave

back and forth in response to

the

drive

voltage. Because the mirrors

are very

small,

the modulation rates might

be

pushed

to perhaps 100,000 activations per

second.

If the mirrors were used to

reflect

light

from an intense light

emitter, a nice

source

of modulated light could

be

Figure

3j

produced.

Page

32

of 68

Optical

Through-the-Air Communications Handbook

-David A. Johnson,

PE

Table of Contents:

- LIGHT THEORY:The Spectrum, Human Eye Response, Silicon Detector Response

- LIGHT DETECTORS:The Silicon PIN Photodiode, Active Area, Response Time

- LIGHT EMITTERS:Light Emitting Diodes (LEDs), Solid State Semiconductor Lasers

- LIGHT SYSTEMS CONFIGURATIONS:Opposed Configuration, Diffuse Reflective Configuration

- LIGHT PROCESSING THEORY:Lenses as Antennas, Light Collimators and Collectors

- OPTICAL RECEIVER CIRCUITS:Current to Voltage Converter Circuits, Post Signal Amplifiers

- OPTICAL TRANSMITTER CIRCUITS:Audio Amplifier with Filters, Pulsed Light Emitters