|

Production

and Operations Management

MGT613

VU

Lesson

04

Distinctive

Competencies

The

special attributes or abilities that

give an organization a competitive

edge.

7.

Price

8.

Quality

9.

Time

10.

Flexibility

11.

Service

12.

Location

A.

Operations Strategy

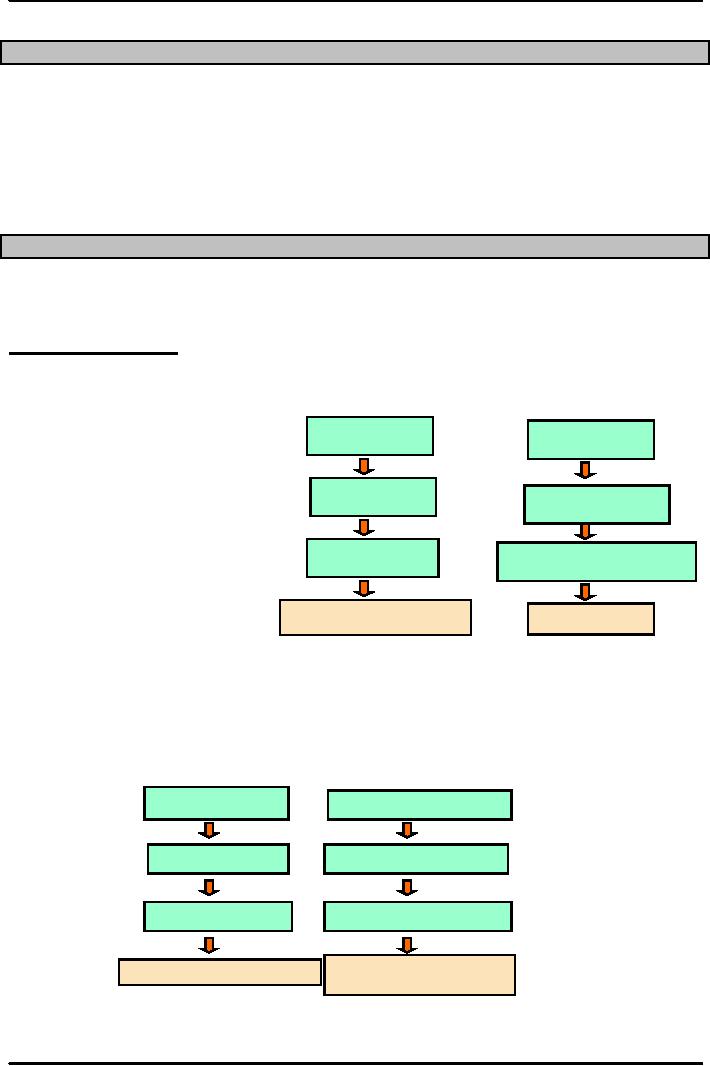

∑Operations

strategy The approach, consistent

with organization strategy that is

used to guide the

operations

function. We first study strategy design

process with example for

manufacturing and

Services.

Strategy

Design Process

Strategy

Process

Example

Customer

Needs

More

Product

Corporate

Strategy

Increase

Organization

Size

Operations

Strategy

Increase

Production Capacity

Decisions

on Processes

Build

New Factory

and

Infrastructure

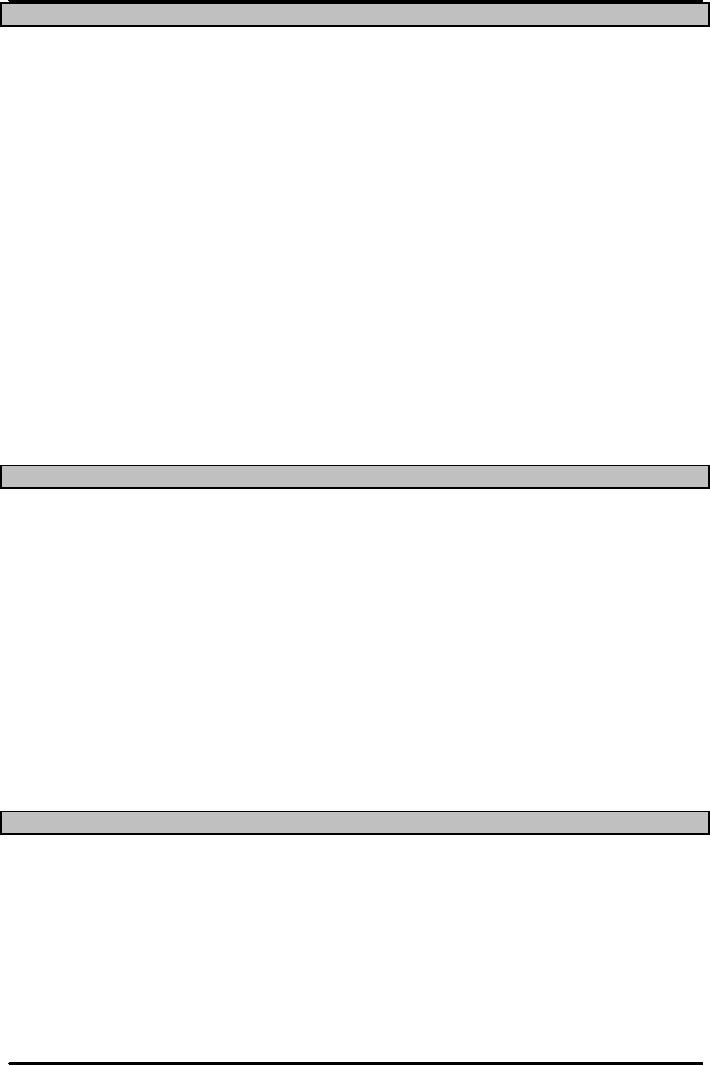

Strategy

Design Process for Services

Strategy

Map

Desired

Results

ancial

Perspective

Improve

Shareholder Value

Customer

Perspective

Customer

Value Proposition

Internal

Perspective

Build-Increase-Achieve

Learning

and Growth

Perspective

A

Motivated and

Prepared

Workforce

14

Production

and Operations Management

MGT613

VU

Relationship

between Operations and Organizational

Strategy

∑Organizational

strategy is

an

over all big picture

for the whole

organization.

Longer

in time horizon

Less

detailed and broader in scope.

∑Operational

Strategy is

Narrower

in scope and in more detail

Prepared

by middle management.

Should

be in line with the Organization

strategy

∑Operational

Strategy if

Designed

and implemented successfully can make an

organization more successful.

Organizations

started focusing on operational

strategies in early 1990s

before that

organizations

focused on financial and marketing

strategies.

Operational

strategies mostly function on

two dimensions of quality

management and

service/manufacturing

strategy.

An

operations Manager should avoid

SUBOPTIMIZATION meaning his

operational strategy for the

department

and divisions goals should not harm the

overall Organizational strategy. He

should opt for

systems

approach or a big picture approach or

strictly base his operations strategy on

Organizational

strategy.

Operations

Strategy for Service

Organizations

Service

Organizations in Pakistan function with a

very detailed and elaborative Operations

Strategy. It

is

important to identify the Strategy

Design Process and able to recognize the

concepts associated

with

Strategy

Formulation. Service Organizations are no

exceptions and work diligently to

identify, nurture

and

protect their distinctive

competencies. Service Organizations are

busy carrying out

detailed

environmental

scanning and also periodically

carryout SWOT

Analysis.

As

operations manager of a service based

organization, one should be able to

understand the

importance

of both Order qualifiers and

Order winners. Order

qualifiers

are

those significant characteristics

that service customers perceive as

minimum standards of

acceptability

to be considered as a potential purchase

while order winners

are

the characteristics of an organization's

services that cause it to be

perceived as better than

the

competitors

services. A bank offering 10 percent

return on customers' holdings would be an

order

qualifier

but if the same service has an

additional characteristic of some added

feature like

availability

of

interest free loans for purchase of

car or building of homes,

then the banks service becomes

order

winner.

Steps

in Developing a Manufacturing/Service

Strategy

1.

Segment the market according to the

product/Service group ( A person

interested in buying a sedan

car

would rarely show interest in buying an

SUV car, the market segmentation should

be just and

judicious)

2.

Identify product/Service requirements,

demand patterns, and profit margins of

each group ( Your

Market

research department should be able to

capture these with the help of MIS

systems)

3.

Determine order qualifiers

and winners for each

group ( Order Qualifiers

would meet customer

requirements

and Order Winners would

satisfy customers)

4.

Convert order winners into

specific performance requirements ( Continuous

improvement always

helps

and it is what the Japanese

has perfected through

KAIZEN)

15

Production

and Operations Management

MGT613

VU

Key

External Factors

1.

Economic

conditions should include

both Micro and Macro

Economics.

2.

Political

conditions require the organization to

carryout PEST analysis.

3.

Legal

environment relates to government

regulations for investor

protection.

4.

Technology

.Gap Analysis focusing

market leaders in the respective

field.

5.

Competition

so as to expect no free lunches or no

monopolies.

6.

Markets

are always free markets

till proven otherwise

Key

Internal Factors

1.

Human Resources include

Trained, skilled and qualified

employees.

2.

Facilities and equipment are a

good source for motivation,

and obtaining competitive

advantage

over

your competitors.

3.

Financial resources. A higher

Free cash flow makes a

company outperform its

competitors.

4.

Customers include repeat

customers, as well as customer

relationship Management.

5.

Products and services relates to

how does the organization values

itself whether it

provides

products

or services that add

value)

6.

Technology .Legacy Systems or

Technology that is competitive and

has the potential to

gain

competitive

advantage.

7.

Suppliers .Companies have taken care of

the supplier issue by making

use of effective

Supply

Chain

Management Strategies or use vertical or

horizontal integration techniques.

Strategic

Service Vision

Service

Concept includes

Service

Levels refer to the important

elements of the service to be provided,

usually stated in

terms

of results produced for

customers.

Perception

corresponds to the elements perceived by

the target market segment, by the

market

in

general, by employees, & by others. How do

customers perceive the service

concept.

Delivery

focuses on the efforts in terms of

the manner in which the service is

designed,

delivered,

marketed.

Strategic

Service

Vision

Operating

Strategy

Focus

Area includes important

elements of the strategy: operations,

financing, marketing,

organization,

human resources, control. Also the

central service area along

with the location of

investments

( human resource or Technology).

Central

Operations to control quality and

costs, improve measures,

incentives, rewards. The

expected

results should be evaluated in

terms of, quality of service,

cost profile,

productivity,

morale/loyalty

of servers.

Service

Delivery System

The

important features of the service

delivery system include role

of people, technology,

equipment,

layout,

procedures

The

capacity it has to provide at peak

levels

The

extent to which it should

help to insure quality standards,

differentiate the service from

competition,

provide barriers to entry by

competitors.

Relatively

Low (as compared to

manufacturing) Overall Entry

Barriers

Economies

of Scale Limited (not always

but most of the time)

High

Transportation Costs

Erratic

Sales Fluctuations

16

Production

and Operations Management

MGT613

VU

No

Power Dealing with Buyers or

Suppliers

Product

Substitutions for Service

High

Customer Loyalty

Exit

Barriers

Competitive

Service Strategies (Overall

Cost Leadership)

Seeking

Out Low-cost

Customers

Standardizing

a Custom Service

Reducing

the Personal Element in Service Delivery

(promote self-service)

Reducing

Network Costs (hub and

spoke)

Taking

Service Operations Off-line

Competitive

Service Strategies (Differentiation)

Making

the Intangible Tangible

(memorable)

Customizing

the Standard Product

Reducing

Perceived Risk

Giving

Attention to Personnel

Training

Controlling

Quality

Note:

Differentiation in service means being

unique in brand image, technology

use, features, or

reputation

for customer service.

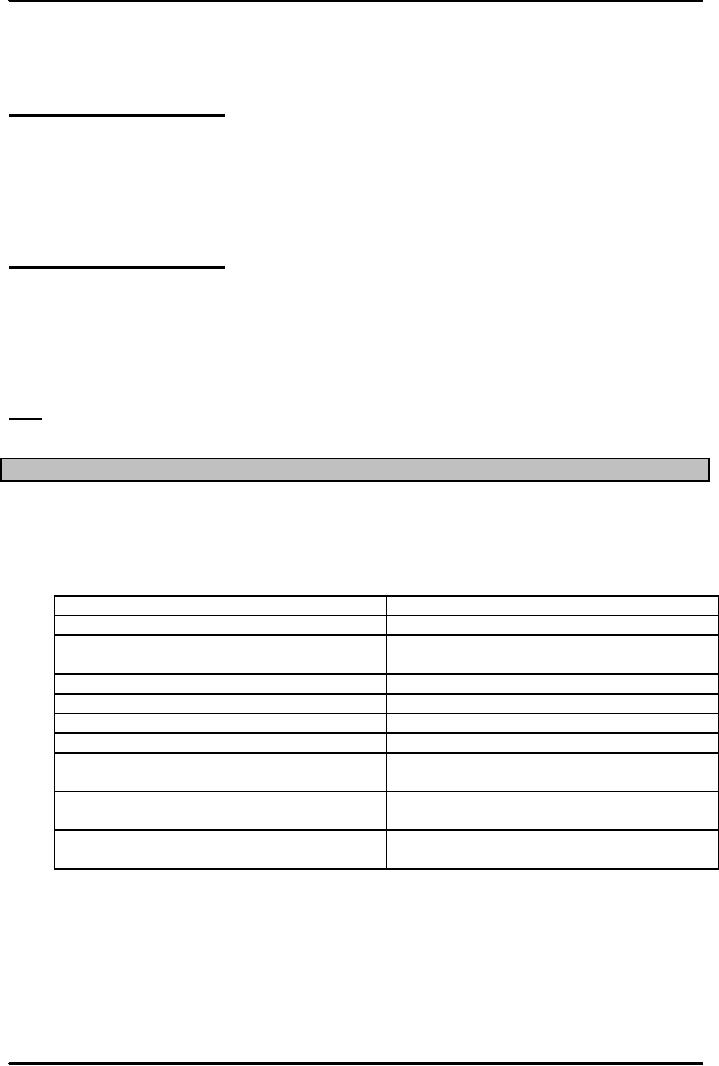

Customer

Criteria for Selecting an

online Banking Service Provider in

Pakistan

We

can apply our concepts of

service to an online banking service

provider in Pakistan. We

investigate

the

service being provided by the bank by

checking for availability, convenience,

dependability,

personalization,

price, quality, reputation, safety

and speed. This should

help us understand the strength

of

service industry in a competitive

environment especially in our

country of Pakistan.

CHARACTERISTIC

REMARKS

Availability

24

hour ATM or online financial

transaction

Convenience

Site

location from any

internet equipped

computer

in and out of Pakistan

Dependability

On-time

performance and correct information

Personalization

Know

customer's name and ID

Price

The

fee a customer pays for

online service

Quality

Reflected

in service.

Reputation

Word-of-mouth

and audited and examined by

neutral

bodies.

Safety

Customers

online data is safe and

inaccessible

to

others and hackers

Speed

Avoid

excessive waiting in website loading

and

data

available online.

Online

banking service providers are

often checked for:

Anti-competitiveness

i.e. whether are not

allowing other online

banking service providers to

enter

the market by constructing barriers to

entry

Fairness

indicates the concept of Yield

management. Meaning whether the

bank is actually

providing

the same return as it had promised to the

customer

Invasion

of Privacy. Calling people

through telephones or visiting offices

thus making use of

Micro-marketing

concepts, which often makes

the patron and customer feel

that his privacy

has

been

compromised.

17

Production

and Operations Management

MGT613

VU

Data

Security. Banks make it a point

that the financial records of the

customers are not

accessed

by

unauthorized personnel.

Reliability.

Banks always strive that

their service is reliable and considered

safe and usable by

its

customers. Most online

banking service providers allow

its customers to access

their account

statement,

free of cost.

Service

Purchase Decision

In

order to understand further we evaluate

the service organizations in terms of

Purchase Decision.

Service

Qualifier: To be

taken seriously a certain

level must be attained on the

competitive

dimension,

as defined by other market

players. Examples are cleanliness for a

fast food

restaurant

or safe aircraft for an

airline.

Service

Winner: The

competitive dimension used to make the

final choice among competitors.

Example

is price of airline ticket or

bus fare.

Service

Loser:

Failure to deliver at or above the expected

level for a competitive

dimension.

Examples

are failure to repair auto

(dependability), rude treatment (personalization) or

late

delivery

of package (speed).

Using

Information to Categorize Customers ( For

Call Centers in Pakistan)

Coding

grades customers on how

profitable their business

is.

Routing

is used by call centers to place

customers in different queues

based on customer

code.

Targeting

allows choice customers to have fees

waived and get other hidden

discounts.

Sharing

data about your transaction

history with other firms is

a source of revenue.

Quality

and Time Strategies

∑Quality-based

strategies

Focuses

on maintaining or improving the quality

of an organization's products or

services

Quality

at the source

∑Time-based

strategies

Focuses

on reduction of time needed to accomplish

tasks

Time

Based Strategies: Organizations have registered

reduction in time by employing

the

following

"6" time based strategies.

There are 6 time based

strategies namely:-

1.

Planning Time The time

required to react to a competitive

threat, or to adopt

new

technologies,

or to approve changes to an existing

facility

2.

Products/Service Design Time The

time needed to develop or

market new or redesigned products

or

services

3.

Processing Time The time

required to produce goods or services,

includes repairing

equipment,

quality

training, inventory

etc

4.

Changeover Time is the time needed to

change from producing one

type of product or service to

another.

New model, new insurance

/health service.

5.

Delivery Time is the time

needed to fill

orders.

6.

Response Time for complaints

is the required to improve the model or

service features according to

customer

inputs and improving employee

working conditions.

18

Table of Contents:

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Decision Making

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Strategy

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Service Delivery System

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Productivity

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:The Decision Process

- INTRODUCTION TO PRODUCTION AND OPERATIONS MANAGEMENT:Demand Management

- Roadmap to the Lecture:Fundamental Types of Forecasts, Finer Classification of Forecasts

- Time Series Forecasts:Techniques for Averaging, Simple Moving Average Solution

- The formula for the moving average is:Exponential Smoothing Model, Common Nonlinear Trends

- The formula for the moving average is:Major factors in design strategy

- The formula for the moving average is:Standardization, Mass Customization

- The formula for the moving average is:DESIGN STRATEGIES

- The formula for the moving average is:Measuring Reliability, AVAILABILITY

- The formula for the moving average is:Learning Objectives, Capacity Planning

- The formula for the moving average is:Efficiency and Utilization, Evaluating Alternatives

- The formula for the moving average is:Evaluating Alternatives, Financial Analysis

- PROCESS SELECTION:Types of Operation, Intermittent Processing

- PROCESS SELECTION:Basic Layout Types, Advantages of Product Layout

- PROCESS SELECTION:Cellular Layouts, Facilities Layouts, Importance of Layout Decisions

- DESIGN OF WORK SYSTEMS:Job Design, Specialization, Methods Analysis

- LOCATION PLANNING AND ANALYSIS:MANAGING GLOBAL OPERATIONS, Regional Factors

- MANAGEMENT OF QUALITY:Dimensions of Quality, Examples of Service Quality

- SERVICE QUALITY:Moments of Truth, Perceived Service Quality, Service Gap Analysis

- TOTAL QUALITY MANAGEMENT:Determinants of Quality, Responsibility for Quality

- TQM QUALITY:Six Sigma Team, PROCESS IMPROVEMENT

- QUALITY CONTROL & QUALITY ASSURANCE:INSPECTION, Control Chart

- ACCEPTANCE SAMPLING:CHOOSING A PLAN, CONSUMERíS AND PRODUCERíS RISK

- AGGREGATE PLANNING:Demand and Capacity Options

- AGGREGATE PLANNING:Aggregate Planning Relationships, Master Scheduling

- INVENTORY MANAGEMENT:Objective of Inventory Control, Inventory Counting Systems

- INVENTORY MANAGEMENT:ABC Classification System, Cycle Counting

- INVENTORY MANAGEMENT:Economic Production Quantity Assumptions

- INVENTORY MANAGEMENT:Independent and Dependent Demand

- INVENTORY MANAGEMENT:Capacity Planning, Manufacturing Resource Planning

- JUST IN TIME PRODUCTION SYSTEMS:Organizational and Operational Strategies

- JUST IN TIME PRODUCTION SYSTEMS:Operational Benefits, Kanban Formula

- JUST IN TIME PRODUCTION SYSTEMS:Secondary Goals, Tiered Supplier Network

- SUPPLY CHAIN MANAGEMENT:Logistics, Distribution Requirements Planning

- SUPPLY CHAIN MANAGEMENT:Supply Chain Benefits and Drawbacks

- SCHEDULING:High-Volume Systems, Load Chart, Hungarian Method

- SEQUENCING:Assumptions to Priority Rules, Scheduling Service Operations

- PROJECT MANAGEMENT:Project Life Cycle, Work Breakdown Structure

- PROJECT MANAGEMENT:Computing Algorithm, Project Crashing, Risk Management

- Waiting Lines:Queuing Analysis, System Characteristics, Priority Model