|

Page

56 of 97

Figure

4-8: Model 375 100Base-T to

Fiber Transceiver for Fast

Ethernet

The

application illustrated in Figure

4-6 applies to the Model

375. You merely have to

substitute a Fast

Ethernet,

100Base-T Ethernet LAN, for

the 10Base-T Ethernet LAN and

substitute a Model 375 for

the

Model

373.

CHAPTER

5

EXPLOITING

THE ADVANTAGES OF FIBER OPTIC CABLE IN THE

INDUSTRIAL

ENVIRONMENT

5.1

Data Communications in the Industrial

Environment

Our

attention is now drawn to

the problem of data

communications in the industrial

environment. This is

the

problem of data communications in

the manufacturing facility. It is

the problem of data

communications

on the factory floor or in

the process control plant.

Data communications in these

premises

can significantly benefit by using

fiber optic cable as the

Transmission Medium.

Let

us begin by describing the

industrial environment from a

data communications

perspective.

What

type of data communications is

going on here? Typically,

the situation is illustrated in

Figure 5-1.

There

is a Master Computer located

somewhere in the manufacturing

facility. In the past this

was

usually

a mini-computer. Presently, it is either

a workstation or PC. The

Master Computer is

communicating

with any of a number of data

devices. For example, it may be

controlling automated

tools

and sensors. It may also be exercising

control by querying and receiving

data from different

monitors.

These data devices are located

throughout the facility. The

illustration provided by Figure

5-1

shows

a machine tool, but in

actuality the number of

different automated tool

types, sensors and

monitors

may be very large. By way of

example, it may extend to

well over 100 in a

semiconductor

Page

57 of 97

fabrication

facility.

The

control procedure exercised by the

Master Computer usually consists of

sending a message out

and

receiving

a message back. It may be

sending automated tool or

sensor an instruction. It may

then receive

back

either an acknowledgement of instruction

receipt or a status update of some sort.

In like manner,

the

Master Computer may send

queries to a monitor and receive back status

updates.

Figure

5-1: Data Communications in

the industrial

environment

As

is readily evident, the

whole control procedure is

executed using data

communications with

appropriate

signaling devices (modems) and other

needed equipment located at

both the Master

Computer

and the data device

locations. Required data

transmission rates need not

be significantly large.

On

the other hand, in the

industrial environment reliability

requirements are quite

stringent. This is so

regardless

of whether reliability is measured by

either BER or link up-time

or some other

parameter.

The

consequences of an unreliable data

communications link may be a mere

annoyance when it

comes

to

office communications. However,

consequences may be catastrophic in a

manufacturing operation.

Literally,

an unreliable link could close

down a whole plant.

Generally,

the type of situation

described above leads the

data communications in the

industrial

environment

to follow an inherently hierarchical

architecture. This type of

architecture is shown in

Figure

5-2. The Master Computer is

located near a communications closet.

The modems and/or

other

communications

equipment (e.g., surge suppressors,

isolators, interface converters)

needed by the

Master

Computer to effect links to

the data devices are usually

rack-mounted in a card cage placed in

the

communications

closet. Cabling then extends

out from the card cage to

the individual data devices.

At

the

data device end the matching

communications equipment may

either be stand-alone or DIN

Rail

mounted.

With the latter, the

communications equipment snap

onto a rail mounted on a

wall or mounted

on

some convenient cabinet near

the data device. DIN Rail

mounting will be discussed in greater

detail

toward

the end of this

chapter.

Page

58 of 97

Figure

5-2: Data communications

architecture usually found in the

industrial environment

It

is important to note that

this is the general case

not the absolute case. If

the Master Computer has

just

1

or a few ports there may be

no need for a card cage. All

data communications equipment

may then be

of

the stand-alone type.

There

are several topologies

associated with this type of

hierarchical architecture. The

topology could be

a

star with a cable extending out

from the card cage hub to

each data device. Each ray

of the star is

simultaneously

operating as data communications

link. The topology could be

a multi-dropped daisy

chain,

using the RS-485 interface

standard. This is particularly suited to

a polling, query-response,

data

communications

scheme - the type of

communications being carried

out by the Master Computer.

The

topology

could even be a broadcast

bus, the type used by an

Ethernet LAN.

5.2

The Problem of

Interference

In

considering data communications in

the industrial environment a

key concern is the problem

of

interference.

This is an underlying concern

regardless of whether or not

the architecture is

hierarchical

or

not and regardless of what

topology is employed.

From

an interference point of view

the manufacturing facility

represents a stressed environment.

The

presence

of high current equipment

such as the automated tools

results in the propagation

of

electromagnetic

pulses that interfere with

the data communications

links. Proper grounding is

always

difficult

in the industrial environment.

Ground loops and resulting

ground currents can cause

transmitted

data

to be demodulated in error.

In

the past, UTP copper cable was

the transmission medium of

choice for the industrial

environment.

Why?

Principally, because of there was a

lot of experience in dealing with

it. There are a number

of

different

ways of handling the problem

of intense interference when

UTP copper cable is employed in

this

environment. Sponges can be inserted

into a data communications

link to protect against surges.

Isolators

can be inserted into a data

communications link to protect against

ground loops. Single

ended

serial

communications can be replaced with

serial communications employing

differential signaling

based

upon the RS-422 standard.

Differential signaling, with

sufficient balance, allows

electromagnetic

interference

of the type prevalent on the

factory floor, to cancel

itself during the data

communications

reception.

But

what about fiber optic cable

as the Transmission Medium, doesn't

this have great

interference

protection?

Good point! If fiber optic

cable is employed in the industrial

environment concerns

about

interference

can vanish. This Transmission

Medium is simply not

affected by the

electromagnetic

interference

plaguing the factory floor.

Furthermore, there is a side

benefit. It was mentioned that

data

transmission

rate requirements are usually modest.

However, this may not

always be so. Using

fiber

optic

cable eliminates the concern

about future bandwidth

needs.

Fiber

optic cable as a Transmission Medium

has been slow in coming to

the industrial

environment.

This

has been principally due to

cost. However, this is

changing as the price of

fiber optic cable

steadily

decreases.

There

are two possible ways by

which fiber optic cable

based data communications

may be introduced

Page

59 of 97

into

a given manufacturing facility. In

the first way, a fiber

optic cable based network

may be introduced

from

the ground up. In other

words, it is installed where no

network previously existed in

the facility. In

the

second way, fiber optic

cabling may be patched into a

network already installed, a

pre-existing

network

that was based on UTP copper

cable.

Today,

if you are considering

installing a network from

the ground up then you

are talking about

installing

an Ethernet LAN with a fiber

optic cable Transmission Medium. In

the past, token ring

LANs

were

quite popular in factory

settings. They guaranteed maximum

transmission delays and

were

matched

to polling techniques. However,

lately Ethernet has come to

dominate even the

industrial

environment.

Furthermore, there is the advantage of

being able to bridge the

factory floor LAN to

other

Ethernet

based LANs in your

organization.

If

you are installing fiber

optic cable by patching into a

pre-existing UTP copper based

network then you

must

deal with the different

types of data interfaces

that may exist in that

network. These data

interfaces

may

include RS-232, RS-422 and

RS-485. Electrical representations of

data from/to these

interfaces

have

to be converted to/from light pulses

traveling down fiber optic

cable.

5.3

Fiber Optic Data Communications

Products that Can

Help

Telebyte

offers a number of different

products that are well

suited to providing data

communications in

the

industrial environment. These products

are particularly well suited

to the second approach

described

above,

the case where a fiber

optic cable capability is being patched

into a previously existing

UTP

copper

cable network. Several of these will

now be described now.

The

fiber optic cable multiplexer

discussed in Chapter 3 and the

Ethernet LAN Extenders discussed

in

Chapter

4 can be also be used to implement data

communications on the factory

floor. A multiplexer can

be

used to allow the Master

Computer to reach to different automated

tools/sensors/monitors with a

single

fiber optic cable. However,

the cost saving that they

can realize depends upon how

the

tools/sensors/monitors

are clustered. The LAN

Extenders can be used to realize a

total Ethernet LAN

approach

to the problem of data

communications in this

environment.

Model

271 Fiber Optic Auto Powered

Line Driver

Page

60 of 97

Figure

5-3: Model 271 Fiber

Optic Auto Powered Line

Driver

The

Model 271 Fiber Optic Auto

Powered Line Driver is a short

haul modem that employs an

RS-232

data

interface and transmits the

data onto a fiber optic

cable. This modem provides full

duplex,

asynchronous,

data communications over two

fiber optic cables. The

length of the fiber optic

cable can

be

up to 2 km and the data rate as high as

56 KBPS. Performance of the

unit is optimized for

62.5/125-

fiber

optic cable. However, the

modem can also be used with

fiber optic cable having

other dimensions.

The

operating power for the

Model 271 Fiber optic Auto

Powered Line Driver is derived

from the

transmit

data line. This is a real

convenience when an electrical

outlet is not readily

available. The

Model

271 is equipped with a DTE/DCE switch

that reverses pins 2 and 3 of

the RS-232 connector.

This

allows

the modem to support

terminals, printers, computers or

any other RS-232 based

device. The fiber

port

of the unit employs ST

connectors.

One

application of the Model 271 is

illustrated in Figure 5-4.

Notice while this

application deals with

the

factory

environment there is no card cage

shown. Rather, the

application deals with the

situation where

there

is the need for a data

communication link between a

mini-computer located in the

front office of a

company

and a PC located on the company's

factory floor. Both the

front office and the factory

floor are

in

the same building.

Page

61 of 97

Figure

5-4: Example application for

the Model 271

Data

communications carried out

strictly in the front office

may be quite reliable over

UTP copper

cable.

However, in this application

the data link traverses the

boundary to the factory

floor.

Consequently,

there is a need for the

extra reliability provided by

fiber optic cable.

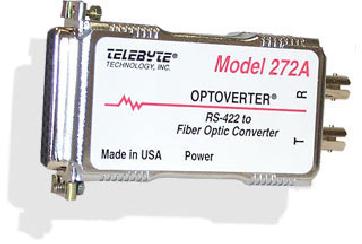

Model

272A RS-422 to Fiber Optic

Converter

The

Model 272A provides the

capability of performing an interface

conversion between full duplex,

RS-

422

signals and their equivalent

for fiber optic

transmission. For applications

where the

transmission

medium

must be protected from

electrical interference, lightning,

atmospheric conditions or

chemical

corrosion

fiber optics is the perfect

solution. The Model 272A

RS-422 to Fiber Optic Line

Driver

handles

full duplex data rates to

2.5 MBPS. The electrical

interface to the RS-422 port

is fully

differential

for transmit and receive

data and is implemented in an industry

standard DB25 connector.

The

fiber optic ports are

implemented using the

industry standard ST connectors. The

design has been

optimized

for 62.5/125 micron fiber

cable, however other sizes

may be used. The optical

signal

wavelength

is approximately 850nm. The

optical power budget for

the Model 272A is 12 dB. In

normal

applications

the distance between a pair of

Model 272A's will be at least 2 km (6,600

ft). Power to

operate

the Model 272A is supplied

by a small, wall mounted, 9

Volt AC transformer and line

cord.

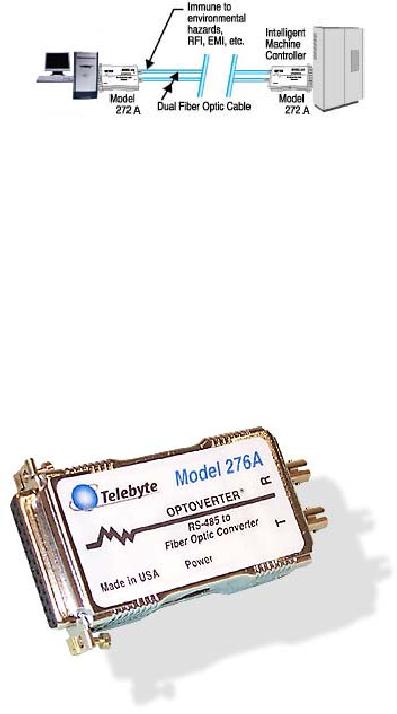

Figure

5-5: Model 272A RS-422 to

Fiber Optic

Converter

One

application of the Model

272A is illustrated in Figure

5-6. This is a simple case

of a single data

communications

link being required on the

factory floor. To avoid

complexities there is no card

cage

although

the extrapolation to one is quite

easy for the reader to

see. The link is between a

PC and an

Intelligent

Machine Controller. Previously,

the link was using RS-422

signaling for

protection.

Consequently,

the data interfaces of both

the PC and the Intelligent

Machine Controller have

RS-422

implemented

with DB25 connectors. The

Model 272A is placed at both

ends of the link and allows

the

data

communications to proceed using

fiber optic cable with its

much greater protection

from

interference.

Page

62 of 97

Figure

5-6: Example application for

the Model 272A

Model

276A - RS-485 to Fiber Optic

Converter

The

Model 276A RS-485 to Fiber

Optic Line Converter accepts

half-duplex data at rates up to 1

MBPS

through

an RS-485 interface. It then

transmits this data onto a

fiber optic cable. Likewise

the unit is able

to

receive data from a fiber

optic cable and send it to a device

through an RS-485 interface.

The RS-485

interface

used by this model is balanced and

implemented in a female DB25

connector.

Figure

5-7: Model 276A - RS-485

Fiber Optic

Converter

The

network architect specifies the

control of data flow in any

RS-485 based communications

facility.

The

Model 276 RS-485 to Fiber

Optic Line Driver provides

the network architect with

the greatest

versatility

by enabling the RS-485

transmitter when data is

detected at the fiber optic

receiver.

In

the Model 276A RS-485 to

Fiber Optic Converter the

fiber optic ports are

implemented using ST

connectors.

Performance is optimized for

fiber optic cable having

dimensions 62.5/125 and for

an

optical

signal with an 830 nm wavelength.

However, fiber optic cable of

other dimensions can be

employed.

The unit provides reliable

communication over a distance of 2

km.

Page

63 of 97

One

application of the Model 276

RS-485 to Fiber Optic Line

Driver is illustrated in Figure

5-8. This is

a

situation in which a PC on the

factory floor is controlling an

environmental control unit and a

number

of

different automated tools.

Control is exercised by communicating

commands and receiving

responses

through

an RS-485 polling network.

However, there is the

complication in that the PC

only has an RS-

232

interface. The environmental

control units and the

automated tools have RS-485

interfaces. The

enhanced

interference protection provided by

fiber optic cable is

required.

Figure

5-8: Example Application for

the Model 276A

In

this application the PC is

connected to the Telebyte

Model 290 RS-232 to

RS-422/RS-485

Concentrator

- Wiring Hub. This allows

conversion of communications from an

RS-232 interface to a

grouping

of both RS-422 and RS-485

interfaces. We are only interested in

the RS-485 ports of

the

Model

290. Data from/to the PC is

converted and is presented on these

RS-485 interfaces. Each of

these

interfaces

is then connected to a Model

276A RS-485 to Fiber Optic

Converter. The Model 276A

then

sends

this data out on a fiber

optic cable or receives the data

from a fiber optic cable. On

the far side of

each

of these fiber optic cables

is another Model 276A. This

takes the data from

the fiber optic cable

and

provides

it either to the environmental

control unit or to one of the

automated machine tools.

Likewise,

it

takes data from these and

transmits it back along a fiber

optic cable to the

PC.

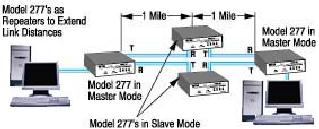

Model

277 RS-232, RS-422, RS-485 to

Multimode Fiber Optic Line

Driver

The

Model 277 Multi Interface

Fiber Optic Line Driver is

pictured as a stand-alone unit in

Figure 5-9.

Also

shown with it is the Model

8277. The Model 8277 is the

same as the Model 277 except

that it is

DIN

Rail mounted.

Page

64 of 97

Figure

5-9: The Model 277

and the Model 8277.

Both units are the

same except the Model 8277 is

DIN Rail

mountable.

The

Model 277 Multi Interface

Fiber Optic Line Driver is a

unique asynchronous fiber

optic modem.

The

optical interface can operate

either by a point-to-point or daisy

chain ring,

multi-drop,

configuration.

The electrical interface can also

operate in either a point-to-point or

multi-drop

configuration.

The network architect

selects the

configuration.

This

unit is appropriate for factory

floor networks where there

is an existing mixture of

point-to-point

and

multi-drop, UTP copper cable based

links. It can easily convert

them to fiber optic

operation with

the

added protection this

provides.

For

a point-to-point configuration, two

Model 277's are connected

back-to-back, to form a high

speed,

full

duplex, fiber optic

link.

In

an optical ring configuration,

three or more Model 277's, in

all 4-wire modes are

daisy chained in a

ring.

The ring will consist of a

Master Model 277 and two or

more slave Model 277's.

Master/slave

modes

are switch selectable. The slaves

pass the received optical

data along with the

transmit data from

their

own electrical interface to

their optical transmitters.

The Master does not

pass the received

optical

data.

A ring of up to 10 Model 277's at a

data rate of 1 MBPS can be formed. To

extend the optical

Page

65 of 97

distance

a pair of Model 277's can be

inserted into the optical

interface to act as a line

extender.

This

unit can support fiber optic

links as long as 1 mile with

a transmission rate as high as 1 MBPS.

The

design

is optimized for transmission

over multi-mode cable at a wavelength of

850 nm.

The

Model 277 electrical interface is

switch selectable between RS-232,

RS-422 and RS-485. As a

result,

this unit is well suited to

assisting in the evolution to fiber

optic cable of existing UTP

copper

cable

based factory networks.

Switch selection enables

data to flow from the

electrical interface

the

optical

transmitter or to be controlled by the

Request To Send (RTS)

line.

Full

duplex, four wire, or

half-duplex, four or two

wire, may be selected when

the RS-422 or RS-485

interface

is selected. The RS-422 or RS-485

interfaces of the Model 277

may operate in a

multi-dropped

or

point-to-point environment.

In

the half duplex mode,

the Model 277 controls the

transmit data line on the

electrical interface.

The

Model 277 is shown in an application in

Figure 5-11. Here several

Model 277's are being

employed

to

extend link length past 1

mile.

Figure

5-10: The Model 277

shown in application to extend

the link length

Model

9271 RS-232 Fiber Optic Auto

Powered Line

Driver

Model

9271 RS-232 Fiber Optic Auto

Powered Line Driver features a standard

DB9 interface for

maximum

performance and reliability of data

transmission over glass

fiber, eliminating the need

for

serial

to nine-pin adapters. In addition, it

brings effective data

communications to manufacturing

environments.

It can be installed in applications

requiring very high data

transmission rates,

offers

resistance

to Electromagnetic Interference (EMI),

and isolation from lightning-induced

current surges

and

ground loops. The unit

employs an RS-232 data

interface, can achieve 56 kbps

asynchronously and

operates

in either half- or full-duplex

modes over dual fibers up to

2 km in length.

Table of Contents:

- Introduction:The Fundamental Problem of Communication, Program

- The Fiber Optic Data Communications Link For the Premises Environment:Fiber Optic Cable

- Exploiting The Bandwidth Of Fiber Optic Cable-Employment by Multiple Users:Sharing the Transmission Medium

- Exploiting The Delay Properties Of Fiber Optic Cable For LAN Extension:Brief History of Local Area Networks

- Exploiting The Advantages Of Fiber Optic Cable In the Industrial Environment:The Problem of Interference

- Serial Data Communications Over Fiber Optic Cable

- Standards

- Glossary