|

Total

Quality Management

MGT510

VU

Lesson

# 38

CAUSE

AND EFFECT DIAGRAM AND OTHER TOOLS OF

QUALITY

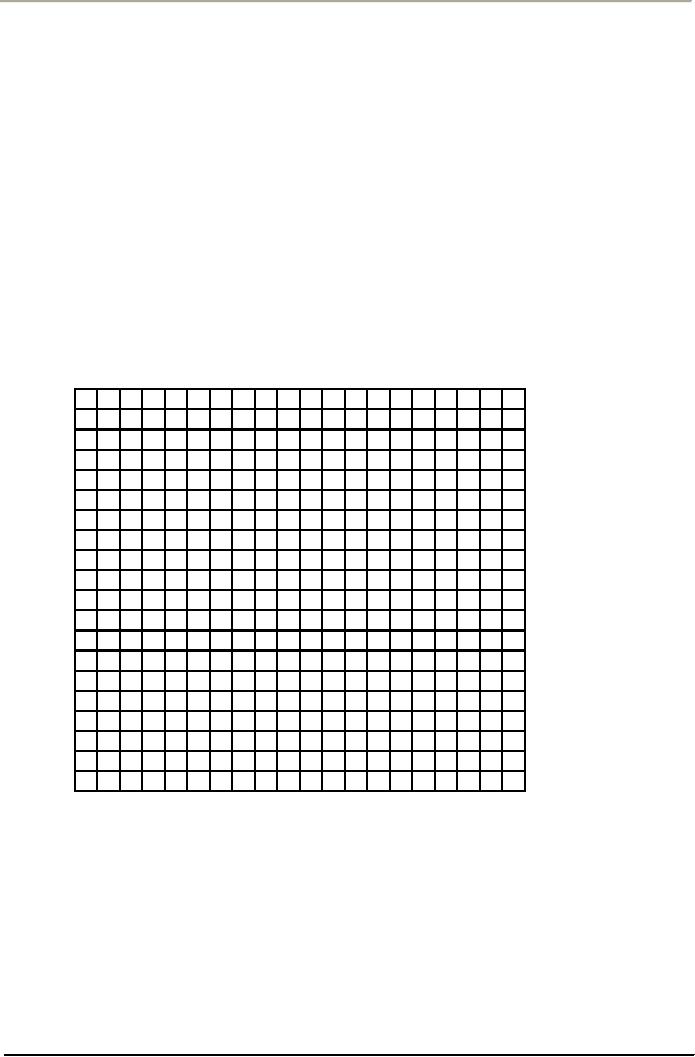

Histograms

Variation

in a process always exists and

generally displays a pattern

that can be captured in a

histogram.

A

histogram is a graphical representation of the

variation in a set of data. It shows the

frequency or

number

of observations of a particular value or

within a specified

group.

Histograms

provide clues about the

characteristics of the population from

which a sample is

taken.

Using

a histogram, the shape of the

distribution can be seen

clearly, and inferences can be

made about

the

population. Patterns can be

seen that would be difficult

to see in an ordinary table of

numbers. The

check

sheet below was designed to

provide the visual appeal of a histogram

as the data are tallied. It

is

easy

to see how the output of the

process varies and what proportion of

output falls outside of

any

specification

limits.

Example

of a Check Sheet for Variable

Data

Frequency

20

19

18

17

16

15

14

X

13

X

12

X

X

11

X

X

X

10

X

X

X

9

X

X

X

X

8

X

X

X

X

7

X

X

X

X

6

X

X

X

X

X

5

X

X

X

X

X

4

X

X

X

X

X

X

X

3

X

X

X

X

X

X

X

2

X

X

X

X

X

X

X

1

X

X

X

X

X

X

X

X

X

X

123456

7

8

9

10

11

12

13

14 15 16 17 18 19 20

Time

to process loan request

(days)

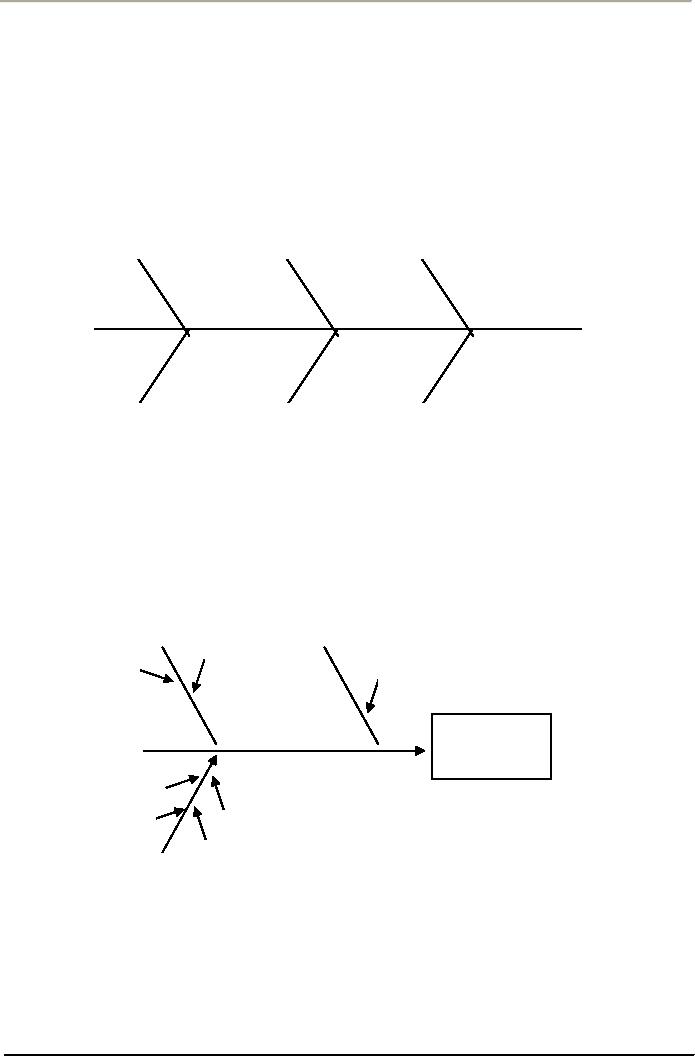

Cause-and-Effect

Diagrams

The

most useful tool for

identifying the causes of problems is a

cause-and-effect diagram, also known

as

a

fishbone or Ishikawa diagram,

named after the Japanese

quality expert who

popularized the concept.

A

cause-and-effect diagram is simply a

graphical representation of an outline

that presents a chain

of

causes

and effects. A team typically

uses a cause-and-effect diagram to

identify and isolate causes

of a

problem.

The technique was developed

by the late Dr. Kaoru

Ishikawa, a noted Japanese

quality expert.

159

Total

Quality Management

MGT510

VU

An

example is shown in figure below. At the

end of the horizontal line is the problem

to be addressed.

Each

branch pointing into the main

stem represents a possible cause.

Branches printing to the causes

are

contributors

to these causes. The diagram

is sued to identity the most

likely causes of a problem so

that

further

data collection and analysis can be

carried out.

IDENTIFYING

CAUSES

Identifying

causes is a critical step in the

process. It involves the pairing

off of causes and effects.

Effects

are the problems that have

already been identified. Say

that one such problem has

been targeted

for

solving. A fishbone diagram

has six spines and

represents the six major

groupings of causes:

manpower

(personnel). Method,

Manpower

Method

Materials

Environment

Machines

Measurement

Sample

Cause-and-Effect Diagram

Materials,

machines (equipment), measurement, and

environment. All causes of work- place

problems

fall

into one of these major

groupings. Using the diagram,

team members' brainstorm causes

under each

grouping.

For example, under the machine

grouping, a cause might be

insufficient maintenance. Under

the

manpower grouping, a cause might be

insufficient training.

A

Cause-and-Effect Diagram

Client

Time

Overload

Unclear

directions

Overload

Word

processing

errors

Inattention

Did

not

No

spell check

understand

directions

Training

Typist

Cause-and-effect

diagrams are usually constructed in a

brainstorming setting so that

everyone can

contribute

their ideas. Usually small

groups drawn from operations or

management work with

an

experienced

facilitator. The facilitator guides the

discussion to focus attention on the

problem and its

causes,

on facts, not opinions. This

method requires significant interaction among

group members. The

facilitator

must listen carefully to the

participants and capture the important

ideas.

160

Total

Quality Management

MGT510

VU

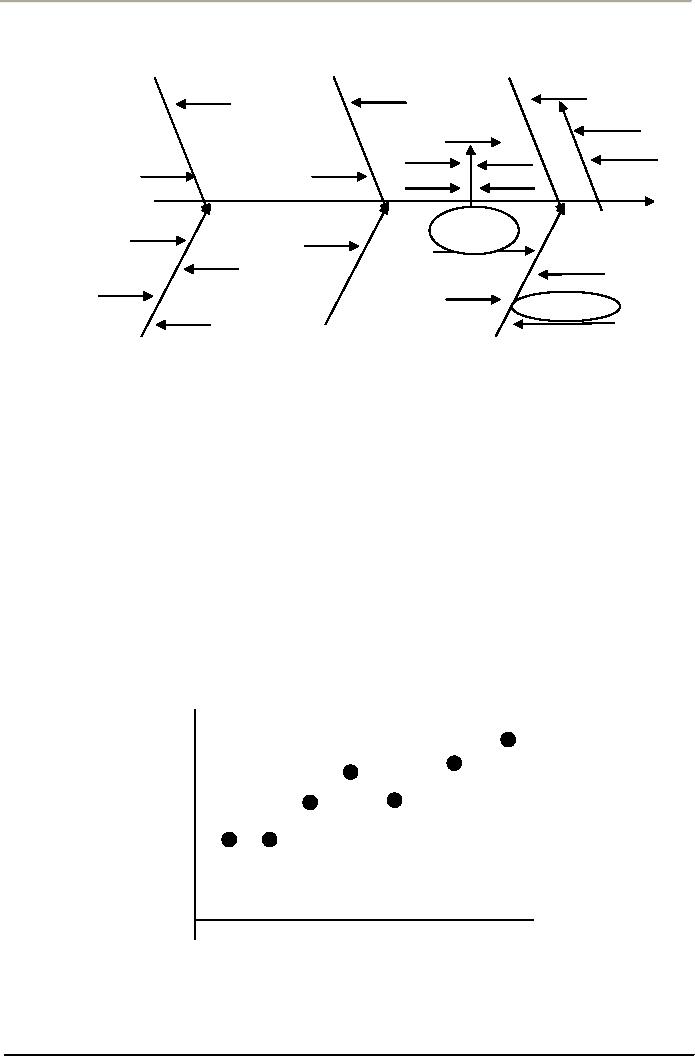

Free-Throwing

Cause-And-Effect Diagram

Materials

People

Measurement

Regulation

backboard

Hit

Player

and

rim

Nothing

but net

Miss

Touch

rim

Short

Coach

Basketball

Coach

Right

Coach

Low

free-

throw

shooting

percentage

Shooting

Video

Practice

position

camera

Indoor

Technique

Ritual

Games

Focus

point

Outdoor

Environment

Equipment

Method

Scatter

Diagram

Scatter

diagrams illustrate relationships between

variables, such as the percentage of an

ingredient in an

alloy

and the hardness of the alloy, or the number of

employee errors and overtime worked

(Figure

3.12).

Typically the variables represent

possible causes and an effect

obtained from cause-and-effect

diagrams.A

general trend of the points going up

and to the right indicates that an

increase in one

variable

corresponds to an increase in the other.

If the trend is down and to the right, an

increase in one

variable

corresponds to a decrease in the other.

If no trend can be seen,

then it would appear that

the

variables

are not related. Of course,

any correspondence does not

necessarily imply that a change in

one

variable

causes a change in the other.

Both may be the result of something

else. However, if there is

reason

to believe causation, the scatter diagram

may provide clues on how to

improve the process.

Scatter

Diagram

Number

of

errors

Volume

of work

161

Total

Quality Management

MGT510

VU

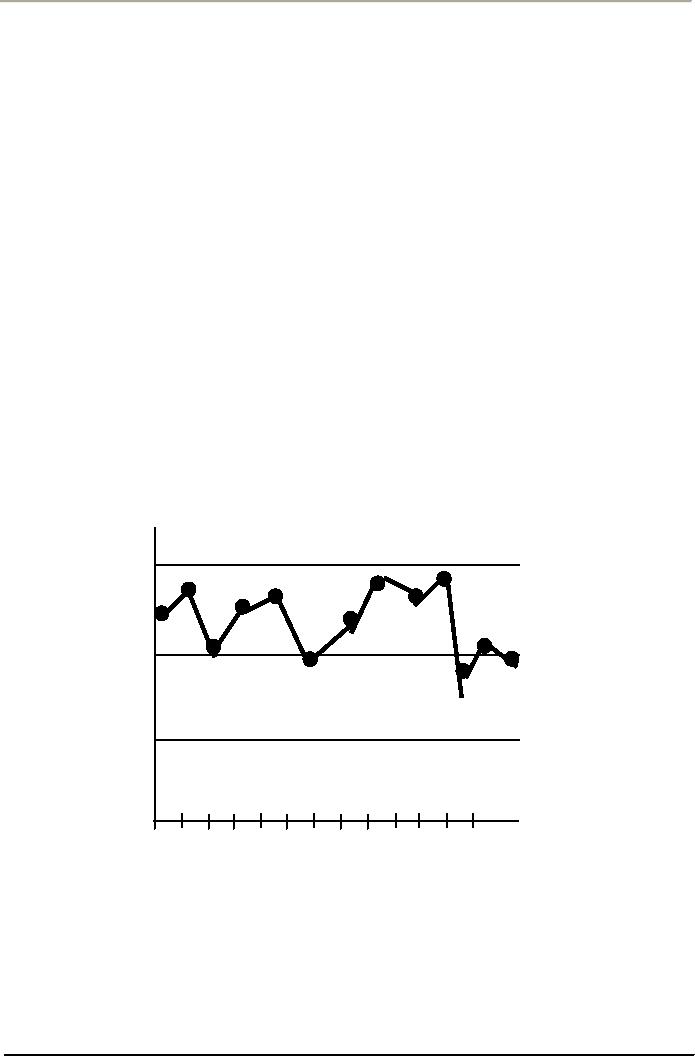

Control

Charts

These

tools are the backbone of statistical

process control (SPC), and were

first proposed by Walter

Shewhart

in 1924. Shewhart was the first to

distinguish between common causes and

special causes in

process

variation. He developed the control chart

to identify the effects of special causes.

Much of the

Deming

philosophy is based on the use of

control charts to understand

variation.

A

control chart displays the state of

control of a process. Time is

measured on the horizontal axis,

and

the

value of a variable on the vertical

axis. A central horizontal

line usually corresponds to the

average

value

of the quality characteristic being

measured. Two other

horizontal lines represent the

upper and

lower

control limits, chosen so

that there is a high probability

that sample values will fall

within these

limits

if the process is under control

that is, affected only by common

causes of variation. If points

fall

outside

of the control limits or if unusual

patterns such as shifts up or

down, trends up or down,

cycles,

and

so forth exist, special causes

may be present.

Two

fundamental mistakes that

can be made concerning

variation are

1.

Treating

special causes as common causes,

and

2.

Treating

common causes as special causes.

Control

charts minimize the risk of

making these two types of

mistakes. As a problem-solving tool,

they

allow

workers to identify quality problems as

they occur and base their

conclusions on hard facts.

EXAMPLE

OF A CONTROL CHART

Percent

shipped

within

24 hours

Upper

97%

Control

Limit

Average

93%

Lower

Control

89%

Limit

Day

1

2

2

4

5

6

7

8

9

10 11 12 13

162

Table of Contents:

- OVERVIEW OF QUALITY MANAGEMENT:PROFESSIONAL MANAGERIAL ERA (1950)

- TOTAL QUALITY MANAGEMENT AND TOTAL ORGANIZATION EXCELLENCE:Measurement

- INTEGRATING PEOPLE AND PERFORMANCE THROUGH QUALITY MANAGEMENT

- FUNDAMENTALS OF TOTAL QUALITY AND RATERS VIEW:The Concept of Quality

- TOTAL QUALITY MANAGEMENT AND GLOBAL COMPETITIVE ADVANTAGE:Customer Focus

- TOTAL QUALITY MANAGEMENT AND PLANNING FOR QUALITY AT OFFICE

- LEADERS IN QUALITY REVOLUTION AND DEFINING FOR QUALITY:User-Based

- TAGUCHI LOSS FUNCTION AND QUALITY MANAGEMENT

- WTO, SHIFTING FOCUS OF CORPORATE CULTURE AND ORGANIZATIONAL MODEL OF MANAGEMENT

- HISTORY OF QUALITY MANAGEMENT PARADIGMS

- DEFINING QUALITY, QUALITY MANAGEMENT AND LINKS WITH PROFITABILITY

- LEARNING ABOUT QUALITY AND APPROACHES FROM QUALITY PHILOSOPHIES

- TOTAL QUALITY MANAGEMENT THEORIES EDWARD DEMING’S SYSTEM OF PROFOUND KNOWLEDGE

- DEMING’S PHILOSOPHY AND 14 POINTS FOR MANAGEMENT:The cost of quality

- DEMING CYCLE AND QUALITY TRILOGY:Juran’s Three Basic Steps to Progress

- JURAN AND CROSBY ON QUALITY AND QUALITY IS FREE:Quality Planning

- CROSBY’S CONCEPT OF COST OF QUALITY:Cost of Quality Attitude

- COSTS OF QUALITY AND RETURN ON QUALITY:Total Quality Costs

- OVERVIEW OF TOTAL QUALITY APPROACHES:The Future of Quality Management

- BUSINESS EXCELLENCE MODELS:Excellence in all functions

- DESIGNING ORGANIZATIONS FOR QUALITY:Customer focus, Leadership

- DEVELOPING ISO QMS FOR CERTIFICATION:Process approach

- ISO 9001(2000) QMS MANAGEMENT RESPONSIBILITY:Issues to be Considered

- ISO 9001(2000) QMS (CLAUSE # 6) RESOURCES MANAGEMENT:Training and Awareness

- ISO 9001(2000) (CLAUSE # 7) PRODUCT REALIZATION AND CUSTOMER RELATED PROCESSES

- ISO 9001(2000) QMS (CLAUSE # 7) CONTROL OF PRODUCTION AND SERVICES

- ISO 9001(2000) QMS (CLAUSE # 8) MEASUREMENT, ANALYSIS, AND IMPROVEMENT

- QUALITY IN SOFTWARE SECTOR AND MATURITY LEVELS:Structure of CMM

- INSTALLING AN ISO -9001 QM SYSTEM:Implementation, Audit and Registration

- CREATING BUSINESS EXCELLENCE:Elements of a Total Quality Culture

- CREATING QUALITY AT STRATEGIC, TACTICAL AND OPERATIONAL LEVEL

- BIG Q AND SMALL q LEADERSHIP FOR QUALITY:The roles of a Quality Leader

- STRATEGIC PLANNING FOR QUALITY AND ADVANCED QUALITY MANAGEMENT TOOLS

- HOSHIN KANRI AND STRATEGIC POLICY DEPLOYMENT:Senior Management

- QUALITY FUNCTION DEPLOYMENT (QFD) AND OTHER TOOLS FOR IMPLEMENTATION

- BASIC SQC IMPROVEMENT TOOLS:TOTAL QUALITY TOOLS DEFINED

- HOW QUALITY IS IMPLEMENTED? A DIALOGUE WITH A QUALITY MANAGER!

- CAUSE AND EFFECT DIAGRAM AND OTHER TOOLS OF QUALITY:Control Charts

- STATISTICAL PROCESS CONTROL (SPC) FOR CONTINUAL QUALITY IMPROVEMENT

- STATISTICAL PROCESS CONTROL….CONTD:Control Charts

- BUILDING QUALITY THROUGH SPC:Types of Data, Defining Process Capability

- AN INTERVIEW SESSION WITH OFFICERS OF A CMMI LEVEL 5 QUALITY IT PAKISTANI COMPANY

- TEAMWORK CULTURE FOR TQM:Steering Committees, Natural Work Teams

- UNDERSTANDING EMPOWERMENT FOR TQ AND CUSTOMER-SUPPLIER RELATIONSHIP

- CSR, INNOVATION, KNOWLEDGE MANAGEMENT AND INTRODUCING LEARNING ORGANIZATION